Development of Industrial Automatic Box Sealing Machine

| ✅ Paper Type: Free Essay | ✅ Subject: Mechanics |

| ✅ Wordcount: 1872 words | ✅ Published: 18 May 2020 |

Industrial Automatic Box Sealing Machine: Introduction

The previous two many years of years has an important in advancement in the field of robots application. A lot more applications are relied upon to show up in space investigation, front line and in different actives of day by day life in the coming years. A robot is a mechanical gadget that performs mechanised errands and developments, as indicated by either pre-characterised program or a lot of general rules and direct human supervision. These errands either supplant or improve human work.

For example, in assembling, constriction or control of overwhelming or risky material. Robot is a basic part in robotizing the adaptable assembling framework that one extraordinarily popular nowadays. Robots are presently in excess of a machine, as robots have turned into the arrangement of things to come as cost work wages and clients request. Despite the fact that the expense of securing mechanical framework is very costly. However as the present quick improvement and an extreme interest in quality, human are never again prepared to do such requests. Innovative work of future robots is moving at an extremely fast pace due to the always improving and overhauling of the quality models of items. Material taking care of hardware is commonly isolated into four principle classifications: storage and handling equipment, designing frameworks, modern trucks, and bulk material handling. In this looked into work material taking care of have been planned by the methods for pneumatic so as to diminish the process duration by teaming up both the vacuum sucker and gripper system in material taking care of robot.

Packaging

Packaging is the technology of using conveyor belts for enclosing or protecting products (food, wood, and material) for storage, pack objects together into containers, sale, and use. Packaging additionally alludes to the procedure of plan, assessment, and production of bundles. Packaging can be portrayed as an organised arrangement of getting ready products for vehicle, warehousing, coordination, seal, and end use. Packaging contains preserves, transports, informs, and sells.

Project Background

The emphasis of the early research into sealing tended to concentrate on the well constrained problem of packing regular shapes. The main objective of the proposed work is to present the advantages of using automated sealing machine which can automatically seal various sized products and to check its performance. Development of fully automated packing machines keep cost factors such as space and personnel at a low level. (Automated Packaging Machine Using PLC, 2015)

Photoelectric Sensors

A photoelectric sensor is another kind of position detecting gadget. Photoelectric sensors are like the ones with an adjusted light pillar that is either broken or reflected by the objective. The control comprises of a producer (light source), a recipient to identify the discharged light, and related hardware that assess and intensify the recognised sign causing the photoelectric output switch to change state.

Keywords: Packaging Machine, Automated, PLC, Switches, Photoelectric Sensor.

Problem Statements

This project is totally based on the robotic arm which work according to programming and the robotic arm work is to only reduce the human effect which apply more on this peak point of the conveyor belt. The concept of using this plc project which revel to used various sensor and contemporary component as robotic arm which they using their employ instead of the robotic arm. In this two conveyor for the transport of the project which easily manufacture in plant. In this the sensor using for pallet hold on the specific direction and place, where robot will put product on pallet when it will full then the second process start but before this doing by the employees of the company which is very expansive things and it quickly response when see the error in the product

Project Objectives

- To reduce the total cost of the project.

- To increase the production rate.

- To increase the total efficiency.

- It reduce the human errors and production transport cost.

- To able to create the simulation robot in NIRTEC software with machine simulation.

Methodology

WORKING METHODOLOGY

Products are approved on conveyor belt. They are detected by the photocell sensor and the counter is set to ‘1’. When the product totally goes through the sensor, SENSOR 1 switches off. At the point when the sensor switches off, clock (recently set to certain delay) begins. After certain delays, robot seals the box. The robot is distinguished by SENSOR 2 and the counter is reset to ‘0’. This procedure is rehashed for the required term. (Shashank M. Lingappa, 2014)

Figure 1 Working Methodology

Figure 2 Working Methodology

The working principle of this PLC programmed project which is created in EASY PLC software. The project is Industrial Automatic Box Sealing Machineby robotic arm. The Project is totally based on the plc software and the requirement of the component which is easily available in software. There are many type of switches and sensor for the plc project mainly the component utilise as robotic arm, inductive sensor, photocell sensor conveyor belt, conveyor roller. The mainly working principle of this project which is sealing of product from the conveyor belt that product manufacture from the industry.

Related work

This section is about point by point history of Automatic Packing machines which utilise various advancements. Here we present just a short history of the subject with exceptional notice of the pioneers in the field and some significant occasions. Programmed Packing Machine depends on identifying results of various sizes arriving in a solitary line. Item will be detected and dependent on the PLC program, packaging happens.

Book Packaging Engineering which gives data on PLC Control of Feed Weight estimation and Automatic Packaging was useful in realizing the different parameters to be considered while box packing.

Wu Wen Jun’s [1].(Jun’s, n.d.)

3.2. Project Components

Photoelectric sensor:

Photoelectric sensor is reasonable for recognition of dark or intelligent items. It can’t be utilised to identify straightforward objects. Also, vibration can cause alignment issues. The emitter and recipient are in one unit. Light from the emitter strikes the objective and the reflected light is diffused from the surface at all angles. In the event that the recipient gets enough reflected light the output will switch states.

At the point when no light is reflected back to the recipient the output comes back to its unique state. In diffuse filtering the emitter is set opposite to the objective. The recipient will be at some point so as to get a portion of the dispersed (diffuse) reflection.

Figure 4 Photoelectric Sensor

Conveyor Belt:

There are two conveyor belts used for the belt. A conveyor line is the conveying mode of a belt transport system (frequently abbreviated to belt transport). A belt transport framework is one of numerous sorts of transport frameworks. A belt transport system comprises of at least two pulleys, with an endless circle of conveying medium—the transport line—that rotates about them. (conveyors, n.d.)

Figure 5 Pallets Running on Conveyor Belt

Robot 1-Axis

The single-axis module type of its high modularity and its wide range of payloads lends itself to applications in diverse industries. The assigned roller and guideway system ensures very quiet running and low sensitivity to environmental cleanliness. The rack and pinion drive system permits excellent dynamic motion with high accuracy.

Figure 6 Robot 1-Axis

Programmable Logic Controller

PLC or Programmable Controller is an advanced PC utilised for automation of electromechanical methods, such a control of apparatus on production line mechanical production systems, diversion rides, or light installations. PLC’s are utilised in numerous ventures and machines. Dissimilar to universally useful PCs, the PLC is intended for numerous data sources and yield plans, broadened temperature ranges, invulnerability to electrical commotion, and protection from vibration and effect. Projects to control machine activity are commonly put away battery-supported up or non-unpredictable memory.

Advantages of PLC:

- PLC is armoured for severe conditions like dust, moisture, heat, cold, etc.

- Maintenance of the PLC is easier, and reliability is greater.

- PLC can be reprogrammed. Conventional controls must be rewired and are often scrapped instead.

- PLC takes less floor space then relay control panels.

- Special purposes such as time-delay actions and counters can be easily implemented using PLC.

- A PLC has ability for extending input/output arrangements.

COMPONENTS REQUIREMENT

- Conveyor Belt X 2

- Photocell Sensors X 4

- Rollers

- Gantry 1-Axis

- Pallets X 3

- Foundation

- Rectangular Work piece X 3

- Results and Discussions

4.1. Input and Output system

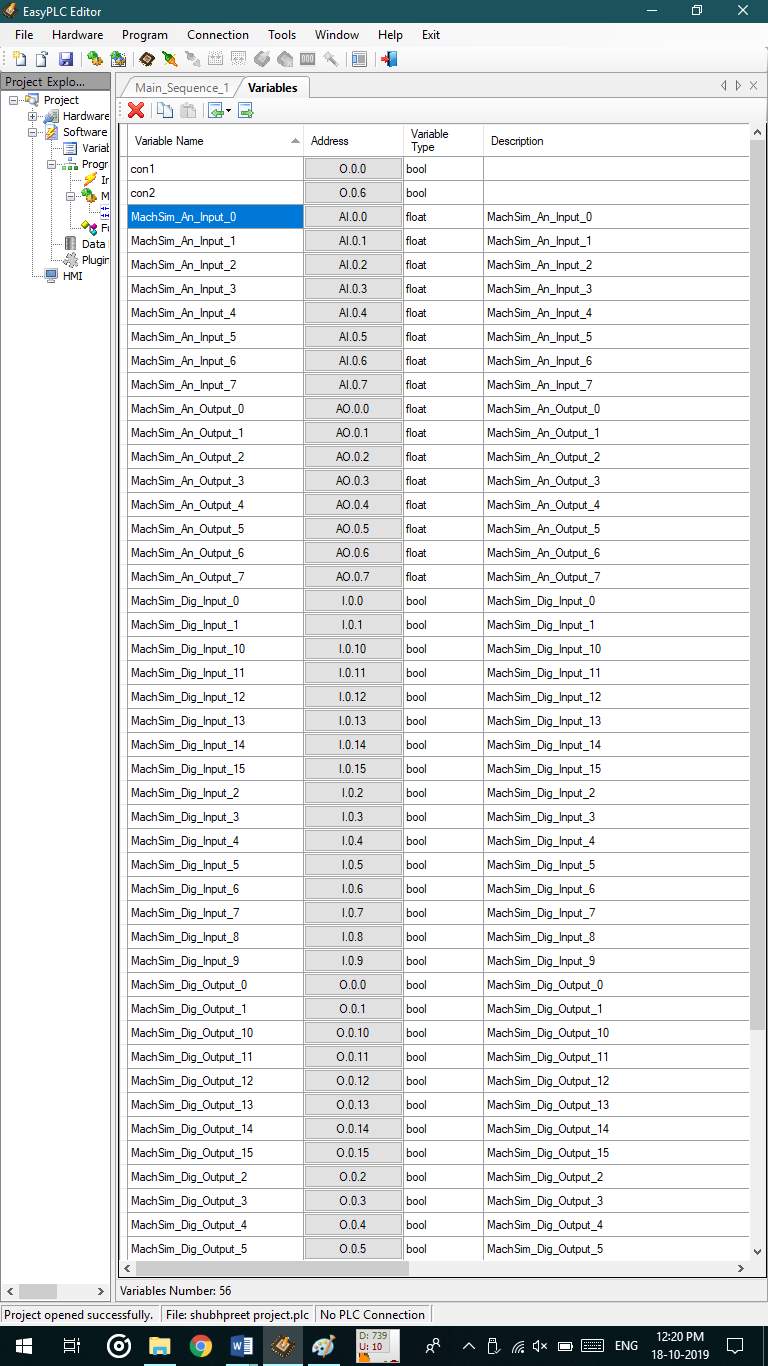

Figure 7 Input and Output Variables

The following Figure 8 Input and Output variables from the ladder programming reveals the input variable address with description of the component which is working according to the ladder logic program.

4.2. Ladder Diagram

Ladder diagrams are specialised schematics ordinarily used to archive modern control logic system. They are designated “ladder” graphs since they take after a ladder, with two vertical rails (supply control) and the same number of “rungs” (horizontal lines) as there are control circuits to represents. On the off chance that we needed to draw a straightforward ladder diagram demonstrating a light that is constrained by a hand switch, it would resemble this.

The following Figure 9 shows that start the ladder logic diagram for the project. In this ladder logic diagram include the emergency switch provides for the project.

4.3. Project Simulation Model and Design

Figure 8 Robotic Arm

In the above Figure 8 Robotic arm can be seen sealing the box to prevent inside materials.

Figure 9 Top View of Seal Robotic Arm

The following Figure 9 shows that the top view of project with some of the component which attached with the conveyor belt and roller. The two photoelectric sensors have been attached to each sides to control robot and conveyor belt.

Figure 10 Robot sealing the Boxes

The following diagram Figure 10 shows the simulation process where 3 product or work parts are coming straight towards the sealing robot. When the box reaches under the robot it works immediately to seal the box.

Figure 11 Box placed on Pallets

The above Figure 11 shows the boxes coming from conveyor roller towards the conveyor belt where pallets are placed.

Figure 12

The following picture Figure 12 shows that all components running on the conveyor roller with pallet and opposite side mount conveyor belt with robotic arm.

Figure 13 Model and Design of project

The above picture Figure 13 shows that model and design of the project and the all simulation created with the PLC system with some of the component mounted according the needs as well as process of the industry with ladder logic diagram. This system is totally about the reduce work for the human effort.

Bibliography

- Automated Packaging Machine Using PLC. (2015, May). Retrieved from Researchgate: https://www.researchgate.net/publication/277670326_Automated_Packaging_Machine_Using_PLC

- conveyors. (n.d.). Retrieved from oceanservice.noaa.gov: https://oceanservice.noaa.gov/facts/conveyor.html

- Jun’s, W. W. (n.d.).

- Jun’s, W. W. (n.d.).

- Shashank M. Lingappa, V. B. (2014, Feb). PLC Controlled Low Cost Automatic Packing Machine. Retrieved from www.semanticscholar.org: https://www.semanticscholar.org/paper/PLC-Controlled-Low-Cost-Automatic-Packing-Machine-Lingappa-Bongale/5e56623c0ea6f672b78c06e3c229f17d4c0499e1

- conveyors. (n.d.). Retrieved from oceanservice.noaa.gov: https://oceanservice.noaa.gov/facts/conveyor.html

- Felker, A. M. Design_and_Implementation_of_an_Automated_Pick_and_Place_System. California.

- inductive sensor. (12, 02 2019). Retrieved from en.wikipedia.org: https://en.wikipedia.org/wiki/Inductive_sensor

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal