Measuring Fluid Viscosity and Effects of Shear Rate

| ✅ Paper Type: Free Essay | ✅ Subject: Chemistry |

| ✅ Wordcount: 2334 words | ✅ Published: 23 Sep 2019 |

Contents

Procedure 1 (Viscosity varying temperature)

Procedure 2 (Varying sheer stress) (Ketchup and Mayonnaise)

Procedure 3 (Viscosity varing shear rate)(cornstarch)

1.1 Risk Assessment Justification

Calibration of Rheometer – The hazard that would cause the biggest issues for the system are the pinch points in the rheometer as large pressure is applied to the system and operators that are not aware of the danger may gain injuries due.

Adjustment of Spindles – The spindles offer light hazards as they may cause small injuries as there are tight points that need to be adjusted for the spindles. These spindles need to be adjusted by hand meaning proper care should be taken in to account to ensure the spindles are secure as they will be moving.

Maintaining of Constant temperature – The system using heating equipment, but the system is full enclosed meaning there is a low chance of burns. The system will be used between the temperatures of 15-30°C. The main danger is the system being used poorly as an operator might set the temperature too hot or the water not being in the system and the heating wire burning out.

Compressing of Fluids – Rheometer acts at large shear rates could cause injury to an operator’s hand if they are pressed close to the user because of this any operator should keep a safe distance when the apparatus is turned on.

Rotation of Spindle – The spindle will rotate in a glass beaker which may cause injury to a person’s hands or by damaging equipment. As is usual with equipment rotating quickly there is a very dangerous hazard of loose clothing and hair being caught up in the machine to reduce this regular laboratory grooming procedure should be followed.

Electrical Apparatus – The wires in the apparatus are mostly insulated but could be damaged if any damage is seen it should be reported to a laboratory attendant as in the experiment water will be used to make up solution and could be very dangerous if this hazard is ignored.

Moving around the lab – General hazards around the laboratory such as slips trips and fails. These are the most common injuries, Theses can be avoid by practicing good house-keeping around the laboratory by keeping the work space clean.

Using Glass Equipment – Glass beakers are used, any breakage of material should immediately clean and placed in the designated glass bin in the back of the laboratory. With lab equipment such as glass the hazards tend to be cause in series as if a beaker breaks it may cause a spillage of the material it was holding if this happens the material should be immediately cleaned before carrying on with the experiment.

2.1 Materials and Equipment

The objective of this experiment is to measure the viscosity of certain fluids and test the affect that shear rate has on them. The fluids that are to be tested in this experiment are ketchup, mayonnaise and a corn starch solution. The reason that a corn starch solution is to be tested is that at higher concentrations of corn starch in water the solution can react very Non-Newtonian. A different measurement device will have to be used for this solution. The solution of corn starch in question is a 50% w/w solution of corn starch and water.

Figure 1 – Ketchup and Mayo to be used in experiment (Elite Daily, 2018)

The samples of the mayonnaise and ketchup will be placed on the plate of the Brookfield’s Rheometer in the lab and the corn starch solution will be placed in a beaker with the spindle from the Brookfield’s Viscometer inside it.

There are two different pieces of equipment being used in this experiment. The first one is the Brookfield Rheometer which will be used for the less viscos fluids stated above. The plate can be heated, and different shear rates can be applied to the plate. Both properties of this piece of equipment allow the rheologic properties of the materials to be acquired.

Figure 2 – Brookfield’s Rheometer (News Medical Life Sciences, 2018)

The second piece of equipment to be used is the Brookfield’s Viscometer. This is the device used to calculate the viscosity of the corn starch solution. The device can be calibrated by navigating through the simple menus on the panel of the device where the rpm and other parameters are set. Using this the shear rate of the corn starch can be calculated and then compared with the values from the other device.

Figure 3 – Brookfield’s Viscometer (Amazon, 2019)

3.1 Procedures

3.1.1 Procedure 1 (Viscosity varying temperature)

- Set the water bath to the starting temperature of 15°C

- Place 1ml of the sample on to the centre of the plate. Ensuring the sample can be seen around the entire circumference of the spindle

- Lower the spindle onto the stage

- Excess material should be removed with the police tool

- Allow the sample and cone to come to equilibration 10-15 minutes is required

- Set the viscometer to remote to allow the system to be used on the computer

- Set the measuring system to C-50-1

- Set the system to measure the viscosity of the material

- Record the value

- After the sample has been tested wipe clean where the sample was with the cleaning material that is provided

- Repeat this for the substances Ketchup, Mayonnaise and corn-starch at 15, 20, 25, 30 °C

- Analyse the data by plotting temperature vs Viscosity

3.1.2 Procedure 2 (Varying sheer stress) (Ketchup and Mayonnaise)

- Set the water bath to the starting temperature of 15°C

- Place 1ml of the sample on to the centre of the plate. Ensuring the sample can be seen around the entire circumference of the spindle

- Lower the spindle onto the stage

- Excess material should be removed with the police tool

- Set the viscometer to remote to allow the system to be used on the computer

- Set the measuring system to C-50-1

- Vary the sheer stress of the system of values 100,200,300 (1/s)

- Set the step time to 5 seconds and run time to 15 minutes

- Run the programme

- Graph the shear stress vs viscosity

- Repeat with two replicates for Ketchup and Mayonnaise

3.1.3 Procedure 3 (Viscosity varing shear rate)(cornstarch)

- Turn on the Brookfield DV-11 + Viscometer

- Make up solution of 50% cornstarch w/w with water in a 600ml bearker

- Attach apporopriate spindle to the viscometer

- Set rpm to the rate required

- Lower the spindle to the 600ml to the submertion point of the spindle

- Run the system and record the viscosity

- Repeat this with different rpms equvilent to (100,200 and 300 1/s shear rate)

- Repeat process twice

- Record values and add to graphs shear stress

4.1 Design of Experiments

4.1.1 DOE 1

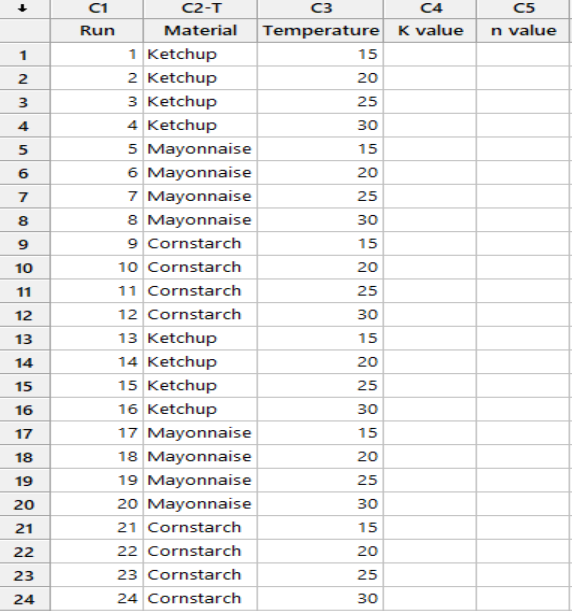

The design of this experiemwnt will be used to determine with a 95% confidence interval wether of not changing the material will effect the viscosity of the materials of ketchup, mayonnaise and cornstarch. The materials are measure between the temperatures between the values of 15-30°C. The will be two replicantes for the system to ensure better results. The K value and n values for the system can be compared to see the classfication of the materials used.

Table 1 – Changing viscosity with temperature of materials Ketchup Mayonnaise and Cornstarch

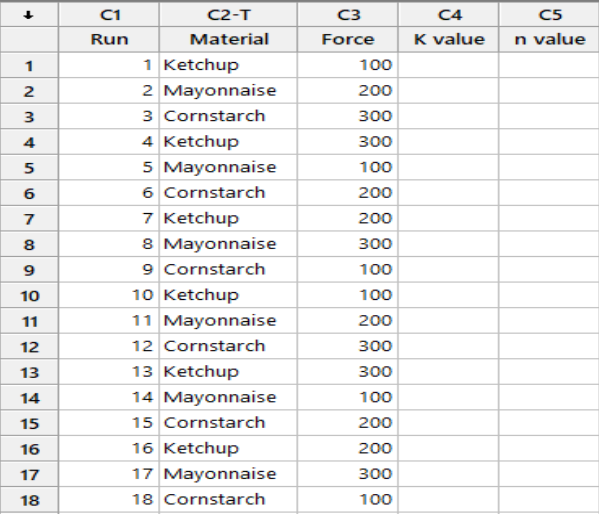

4.1.2 DOE 2

The second design of experiment the temperature is remained constant. The system that is being tested is does material effect the effect of the viscosity on sheer stress with a 95% confidence level. There are two replicates for the system. The system is testing the system under the sheer stress rates of 100,200 and 300 (1/s). The is a large error in the system as the corn-starch solution is too difficult to measure in the same instrumentation as the ketchup and mayonnaise so it is measure separately in a beaker. The instrumentation should be properly calibrated making the values with 5% of there true value making the error much smaller.

Table 2 – Showing the Material (A) Force (B) for ketchup mayonnaise and cornstarch on Minitab

5.1 Theory on the Rheological Properties of Non-Newtonian Fluids

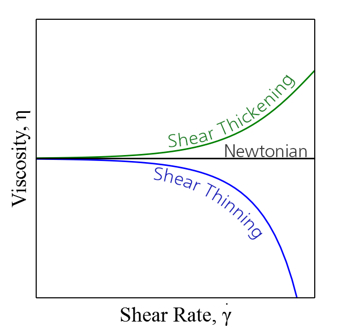

For Newtonian fluids such as water, the viscosity of the substance remains constant regardless of the volume of shear stress applied. However, the viscosity of non-Newtonian fluids can increase or decrease with shear stress. In the case of tomato ketchup, the fluid remains almost solid in the bottom of the container until it is squeezed (i.e. a certain force is applied to the system) after which it easily squirts out. This phenomenon is called “shear thinning” (Chemistry World, 2011). Meanwhile, a mixture of cornstarch and water changes from fluid-like to behaving almost like a solid when additional shear is applied. This phenomenon is called “shear thickening”.

Figure 5.1.1 – Viscosity of Newtonian, Shear Thinning and Shear Thickening fluids as a function of shear rate

[Source: RheoSense, 2019]

Tomato ketchup is a two-phase system in which solid particles of tomato pulp and added spices are dispersed in a colloidal continuous phase that consists of sugars, salts, organic acids, a fraction of soluble pectins, and other compounds of extract dissolved in water. The components of the ketchup which affect the viscosity most include the thickening agents, particularly polysaccharide hydrocolloids (Gujral et. al, 2002). Guar and xanthan gums are found to be the most successful in decreasing serum separation of the fluid (Varela et al., 2003; Sahin and Özdemir, 2007). The rheological properties of ketchup are affected by the rheological characteristics of tomato concentrate (Bayod et. al, 2008; Barbana and El-Omri, 2009). Tomato variety, sieve pore sizes and the temperature of the concentration process are found to be the critical parameters which most affect the rheological characteristics (Sanchez et. al., 2002; Valencia et. al., 2004).

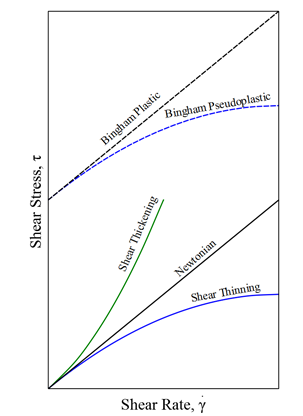

Bingham plastics are fluids which require a minimum applied stress in order to flow. Mayonnaise is one such fluid. They are strictly non-Newtonian, but once the flow starts, they behave essentially as Newtonian fluids. This mean that the shear stress is linear with the shear rate.

Concentrated cornstarch suspensions have been shown to exhibit shear thickening behaviour. This is because as the shear rate increases, the viscosity of the fluid also increases. At rest, the voidage of the suspension is at a minimum and the liquid present in the sample is sufficient to fill the voids completely. At low shearing rates, the liquid lubricates the motion of each particle past another thereby minimising solid-solid friction. Consequently, the resulting stresses are small (Chhabra, n.d.). At high shear rates, however, the mixture expands slightly so that the available liquid is no longer sufficient to fill the increased void space and to prevent direct solid-solid contacts (and friction). This leads to the development of much larger shear stresses than that seen in a pre-dilated sample at low shear rates. This mechanism causes the apparent viscosity η(= σ/γ˙) to rise rapidly with the increasing rate of shear (Chhabra, n.d.).

Figure 5.1.2 – Shear stress as a function of shear rate for several types of fluids

[Source: RheoSense, 2019]

Non-Newtonian fluids flow behaviour can be best modelled using the Herschel Bulkley equation where shear stress,

is measured in mPa. This model is a three parameter yield/power law model which was developed in 1926. The model consists of two distinctive parts. The first term is the Herschel Bulkley yield stress and is denoted by

. The second term,

originates from de Waele and Ostwald. K is the consistency coefficient and is measured in units of Pa

where n is the power law exponent. The Herschel Bulkley equation describes viscoplastic behaviour when n < 1. As the power law (i.e. where

shear thinning n < 1; shear thickening n > 1), Newtonian (i.e. where

n = 1) and Bingham plastic behaviour (i.e. n = 1) can be regarded as special cases, the model represents the flow behaviour of a wide range of fluids (Fester et al., 2012). The second term in the Herschel Bulkley equation,

when plotted on a log-log graph models a straight line with a slope of n. Values of n typically range from 0.2 to approximately 1.4. The further the value of n is from unity, the more non-Newtonian the fluid is.

(5.1)

References

-

Amazon, 2019. Amazon. [Online]

Available at: https://www.amazon.com/BYK-Gardner-7902-Brookfield-Viscometer-Centipoise/dp/B00S183942

[Accessed 15 Febuary 2019]. -

Azomaterials, n.d. Azomaterials. [Online]

Available at: https://www.azom.com/materials-video-details.aspx?VidID=1104 - Barbana, C., & El-Omri, A. (2009). Viscometric behavior of reconstituted tomato concentrate. Food and Bioprocess Technology.doi:10.1007/s11947-009-0270-3.

- Bayod, E., Willers, E. P., & Tornberg, E. (2008). Rheological and structural characterization of tomato paste and its influence on the quality of ketchup. LWT- Food Science and Technology, 41,1289–1300.

-

Chemistry World, 2011. Microscopy reveals why ketchup squirts. [Online]

Available at: https://www.chemistryworld.com/news/microscopy-reveals-why-ketchup-squirts/3002513.article

[Accessed 17 February 2019]. -

Chhabra, R., n.d. Non-Newtonian Fluids: An Introduction. [Online]

Available at: http://www.physics.iitm.ac.in/~compflu/Lect-notes/chhabra.pdf

[Accessed 17 February 2019]. -

Elite Daily, 2018. Making Mayo and Ketchup. [Online]

Available at: https://www.elitedaily.com/p/heres-how-to-make-heinz-mayochup-if-youre-craving-the-new-condiment-8851539

[Accessed 15 2 2019].

- Gujral, H. S., Dharma, A., & Singh, N. (2002). Effect of hydrocolloids, storage temperature and duration on the consistency of tomato ketchup. International Journal of Food Properties, 1, 179–191.

-

News Medical Life Sciences, 2018. RS Plus Controlled Stress Rheometer from Brookfield. [Online]

Available at: https://www.news-medical.net/RS-Plus-Controlled-Stress-Rheometer-from-Brookfield

[Accessed 15 Febuary 2019]. - Sahin, H., & Özdemir, F. (2007). Effect of some hyrocolloids on the serum separation of different formulated ketchups. Journal of Food Engineering, 81, 437–446.

- Sànchez, M. C., Valencia, C., Gallegos, C., Ciruelos, A., & Latorre, A. (2002). Influence of processing on the rheological properties of

- tomato paste. Journal of the Science of Food and Agriculture, 82, 990–997.

- Valencia, C., Sànchez, M. C., Ciruelos, A., Latorre, A., Franco, J. M., & Gallegos, C. (2002). Linear viscoselasticity of tomato sauce products: influence of previous tomato paste processing. European Food Research and Technology, 214, 394 – 399.

- Varela, P., Gámbaro, A., Giménez, A. M., Durán, I., & Lema, P. (2003). Sensory and instrumental texture measures on ketchup made with different thickeners.Journal of Texture Studies, 34, 317–330.

- Veruscha Fester, Paul Slatter and Neil Alderman (2012). Resistance Coefficients for Non-Newtonian Flows in Pipe Fittings, Rheology, Dr. Juan De Vicente (Ed.), ISBN: 978-953-51-0187-1, InTech, Available from: http://www.intechopen.com/books/rheology/resistance-coefficients-for-non-newtonian-flows-in-pipe-fittings

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal