Characterisation of Powder Degradation of PA 11 (Nylon 11) During the Additive Manufacturing Cycles

| ✅ Paper Type: Free Essay | ✅ Subject: Chemistry |

| ✅ Wordcount: 1626 words | ✅ Published: 18 May 2020 |

Characterisation of powder degradation of PA 11 (Nylon 11) during the additive manufacturing cycles

Abstract

Additive Manufacturing (AM) has become a production technique and is changing the way of fabrication. Polyamide-11 is the focus of this research and it is also the one of the main polymers that is being used in AM right now. Results show that the more cycles that the PA-11 is being reused, they tend to show signs of thermal oxidation. This report picks up on the topic and gives an introduction on the material and its properties.

1 Introduction

Polyamide-11 also known as PA11 is a high performing, lightweight bioplastic with a very unique combination of high-performance properties. Compared to other engineering plastics, PA11 has an outstanding level of thermal, chemical and impact resistance over a wide range of flexibility. It is widely used in industrial applications where safety, versatility and durability are very important. Therefore, it is also used as a cost-effective replacement for metal or rubber in very technical applications [1].

The idea of additive manufacturing relies on a better way to produce objects by adding material (powder), unlike the traditional subtractive manufacturing where large amount of material needs to be removed when additive manufacturing (AM) uses the raw material efficiently by building the object layer by layer. The leftover powder can also be reused with minimum processing. Thus, there is an increased in accessibility and significantly saving time in the product development cycle [2,3].

Powder reuse has always been an economic strategy for additive manufacturing. Utilizing the remaining powders from previous builds translates into direct cost savings for the orthopaedic industry which uses additive manufacturing to improve design flexibility. However, the process of reusing the powder during additive manufacturing requires both the material and part quality to be quantitively assessed [4,5].

Powder degradation of the PA11 from different cycles of additive manufacturing will be studied to observe changes in its properties. This study will utilize the surface topography and composition of the sample from different cycles. The Ultimate Tensile Strength (UTS) and Elongation at Break (EAB) will also be studied for different cycles.

2 Objectives

The objective of this thesis is to:

1) Characterizing the properties of PA 11 during additive manufacturing.

2) Understanding how additive manufacturing cycles affect the quality of the material.

3 Literature Review

3.1 Polyamides

High-molecular-weight polyamides are also known as nylon. They are crystalline polymers that are usually produced by the condensation of a diacid and a diamine. There are a couple of types and they are often labelled by their respective numbers. The numbers refer to the carbon atoms present in the molecular structures of the amine and acid, respectively. Like for example, PA11 means there are 11 acids present [6].

3.1.1 Polyamide 11 Applications

The growth in the use of polyamides comes from the increasing use in the automotive industry. When it is employed as an engineering plastic, polyamides are also sometimes used as co-polymers means it is mixed with other materials. Polyamides 11 are usually very useful in applications such as automotive: due to high flexibility and tensile strength, sports and leisure: high abrasion resistance and low coefficient of friction and as well as in the healthcare and medical sector. PA 11 are offer benefits for additive manufacturing because of its good control of particle size, thermal properties and very good processability in laser sintering machines [7,8,9].

3.1.2 Properties and Limitations

The excellent properties of Polyamide 11, such as outstanding impact strength even at low temperatures, resistant to chemicals, resistance to stress cracking and abrasions makes them the choice of material in a wide range of applications especially in the medical industry. While it does have lots of excellent properties, PA 11 does have its own drawbacks. PA 11 has lower heat resistance than other polyamides and has poor resistance to boiling water and UV [9].

3.2 Additive Manufacturing Process

Fresh PA11 powder is first used with a ratio of 30:70 reused powder to build the 3D printed parts in the HP Jet Fusion 4200 3D printer & Processing Station that is available at iOrthotics. The process can be seen in Figure 1 shown below. Powder samples along with dog-bone specimens are then taken out after Step 9 during post-processing and given to us to run different tests on it to study the properties.

Figure 1: Additive Manufacturing Process Steps

4 Experimental

4.1 Scanning Electron Microscope (SEM)

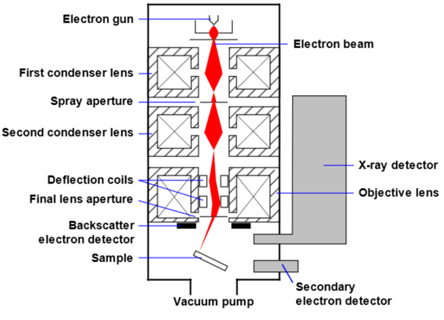

A SEM scans a focused electron beam over a surface to create an image. The electrons in the beam interacts with the sample and thus creating various signals that can be used to obtain information about the material’s morphology and composition. As dimensions of any sample shrinks, many structures can no longer be characterized by light microscopy [10].

Figure 2: SEM image of a PA11 Powder

4.1.1 How a SEM works

The main components of a SEM are:

- Source of electrons

- Electron detector

- Sample chamber

- Computer and display to view the images

- Column down which electrons travel with electromagnetic lenses

First, the electrons are produced at the top of the column and is passed through a combination of lenses and apertures to produce a focused beam of electrons which hits the surface of the sample. The sample is mounted on a small base in the chamber area.

Figure 3: Schematic of a SEM

4.2 Instron Tensile Machine

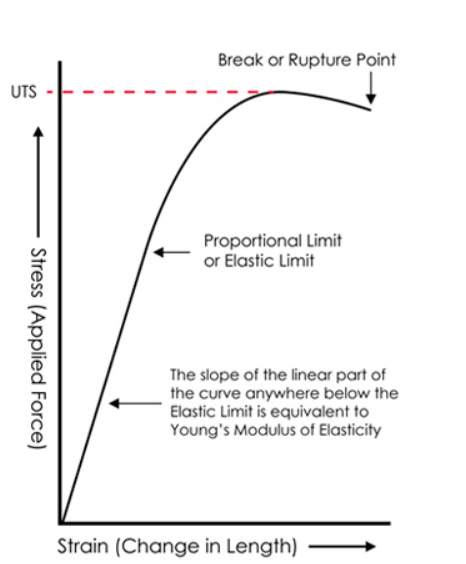

With the Instron machine, tensile tests can be done on the dog-bone specimen obtained from iOrthotics. A tensile test applies a tensile(pulling) force to a material and measures the specimen’s response to the stress applied. From this, it determines how strong a material is and how much it can elongate. For this study, Ultimate Tensile Strength and Elongation at Break is the main results we are trying to find for each cycle and how much it changes.

Figure 4: Tensile Test UTS

5 Results and Discussion

5.1 First Run Microstructure

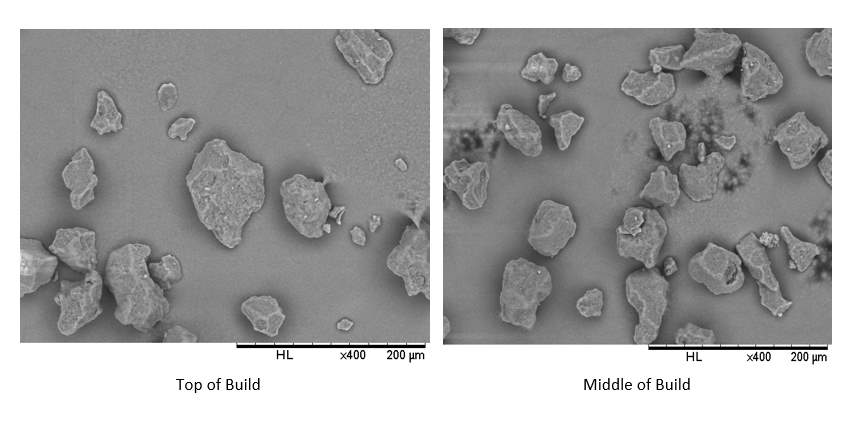

Figure 5: 1st Run Microstructure

From Figure 5, a difference can be seen between the surface morphology of the powder from the top of the build and from the middle of the build. The darker shadows around each powder particle for the middle of the build is probably due to higher heat encompassing the middle of the build during the additive manufacturing. We’ll most likely see this difference be more obvious after more cycles due to thermal oxidation being more apparent in later stages of the additive manufacturing.

6 Research Plan for Semester 2

Figure 6 illustrates the plan that is going to be conducted in Semester One, 2020 which will be commencing on the 24th of February 2020.

Figure 6: Research Plan for Semester 1 2020

More runs of the PA11 will be done in the next semester. More in-depth of the morphology through SEM and mechanical testing of the builds will be done along with DSC if time permits.

Plan to rush and do as much as I can in the first 5weeks of the new semester to catch up on what I’ve missed in the first semester.

Start on the report/presentation slides as soon as the semester starts so I do not rush when the deadline comes.

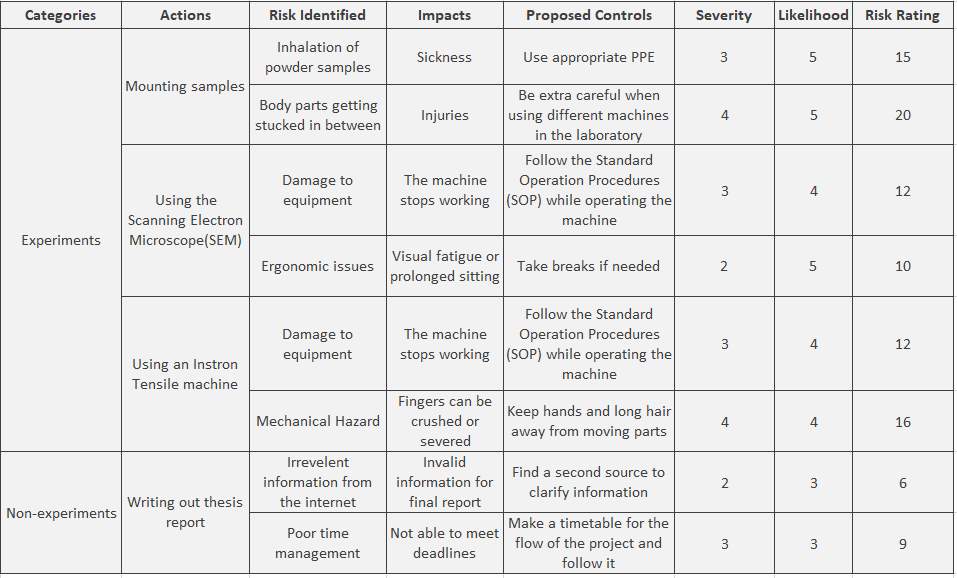

7 Risk Management Plan

References

[1] Devaux, J.-F., Lê, G., & Pees, B. (n.d.). APPLICATION OF ECO-PROFILE METHODOLOGY TO POLYAMIDE 11 . Retrieved from APPLICATION OF ECO-PROFILE METHODOLOGY TO POLYAMIDE 11.

[2] Prakash, K. S., Nancharaih, T., & Rao, V. V. S. (2018). Additive Manufacturing Techniques in Manufacturing -An Overview. Materials Today: Proceedings, 5(2), 3873–3882. https://doi.org/10.1016/j.matpr.2017.11.642

[3] Rahmati, S. (2014). Direct Rapid Tooling. In Comprehensive Materials Processing (Vol. 10, pp. 303–344). Elsevier Ltd. https://doi.org/10.1016/B978-0-08-096532-1.01013-X

[4] Kozlovsky, K., Schiltz, J., Kreider, T., Kumar, M., & Schmid, S. (2018). Mechanical Properties of Reused Nylon Feedstock for Powder-bed Additive Manufacturing in Orthopedics. Procedia Manufacturing, 26, 826–833. https://doi.org/10.1016/j.promfg.2018.07.103

[5] Cordova, L., Campos, M., & Tinga, T. (2019). Revealing the Effects of Powder Reuse for Selective Laser Melting by Powder Characterization. JOM, 71(3), 1062–1072. https://doi.org/10.1007/s11837-018-3305-2

[6] 7 – Polyamides Nylons. (2013). In The Effect of UV Light and Weather on Plastics and Elastomers (pp. 163–191). https://doi.org/10.1016/B978-1-4557-2851-0.00007-4

[7] M. Laura Di Lorenzo, A. Longo & R. Androsch. (2019) Polyamide 11/Poly(butylene succinate) Bio-Based Polymer Blends

[8] The Essential Chemical Industry. (2018, November 8th). Retrieved from http://www.essentialchemicalindustry.org/polymers/polyamides.html

[9] SpecialChem. (2017). Omnexus: The material selection platform. Retrieved from https://omnexus.specialchem.com/selection-guide/polyamide-pa-nylon

[10] Nano Science. (n.d.). nanoScience Instruments. Retrieved from Nanoscience: https://www.nanoscience.com/techniques/scanning-electron-microscopy/

[11] Schmid, M., & Wegener, K. (2016). Additive Manufacturing: Polymers applicable for laser sintering (LS). In Procedia Engineering. Elsevier. https://doi.org/10.3929/ethz-a-010803572

Appendix: Proposed Draft for Final Thesis Report

Acknowledgements

Abstract

Table of Contents

- Introduction

- Goals and Objectives

-

Literature Review

-

Polyamides

- Polyamide 11 Applications

- Additive Manufacturing Processes

-

Polyamides

-

Experimental

-

Scanning Electron Microscope (SEM)

- How a SEM works

- Instron Tensile Machine

-

Scanning Electron Microscope (SEM)

-

Results and Discussion

- 100% new PA11 microstructure

- First Run Microstructure

- Second Run Microstructure

- “”

- UTS and EAB for different runs and so on

- Conclusion

- References

- Appendix

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal