Thermal Damage During the Grinding Process

| ✅ Paper Type: Free Essay | ✅ Subject: Engineering |

| ✅ Wordcount: 770 words | ✅ Published: 23 Sep 2019 |

Abstract:

In this lab a grinding machine was used with several work pieces with the aim of determining the limitations of increasing removal rates during the grinding process with the lab focusing on identifying the conditions in which thermal damage occurs, this can cause other problems like cracks occurring on the work-piece and softening and re-hardening of the material followed by residual stress

In this lab a grinding machine was used with several work pieces with the aim of determining the limitations of increasing removal rates during the grinding process with the lab focusing on identifying the conditions in which thermal damage occurs, this can cause other problems like cracks occurring on the work-piece and softening and re-hardening of the material followed by residual stress

Figure 1 shows results of grinding process. (Sherif, A. 2018)

Figure (1) is a photo of three work-pieces taken at the lab all three pieces show different results the top piece shows no signs of burns (thermal damage) this is because there wasn’t sufficient speed on the piece or wheel. The middle piece shows signs of burns due to the speed of the wheel or the piece however the bottom piece shows no signs of burns even though the same speed was reached, this is because a coolant was used hence the blue discolouration on the piece. From this we know if grinding at high speeds coolant is necessary to reduce chances of thermal damage.

Table of contents:

Abstract……………………………………………………………………………………………………………………………………………. 2

Introduction………………………………………………………………………………………………………………………………………3

Method……………………………………………………………………………………………………………………………………………..4

Theory……………………………………………………………………………………………………………………………………………….4

Results………………………………………………………………………………………………………………………………………………5

Discussion………………………………………………………………………………………………………………………………………….6

Conclusion…………………………………………………………………………………………………………………………………………7

References…………………………………………………………………………………………………………………………………………7

INTRODUCTION:

Grinding is a process in which a work piece is engaged by an abrasive wheel rotating at a certain adjustable speed which cuts smalls chips from the work piece via sheer deformation. This process improves surface finish and abrades hard materials, this process is similar to sanding and because of the speed at which this occurs the abrasive action of grinding generates heat so it’s necessary to flood the cutting area with fluid. (Neailley K., 1988)

The grinding machine spins at a certain speed which is determined by the wheel diameter and manufacturers rations, this is usually done using a formula. The work piece is on a bed with a fixture guiding it, the grinding head is controlled to travel across or the head can be fixed and then piece is instead moved towards the head. Accuracy and fine control of the head or table is possible with the use of a Vernier calibrated wheel. The objective of this lab is to determine the specific energy and using that predict the values of infeed rate (Vƒ) and work piece speed (Vɯ) at which burns occur.

Figure 2 shows how a grinding wheel interacts with a work piece. (Kumar, L. 2013)

(https://www.slideshare.net/lalukumar56027/l9-grinding2012)

Material is removed from the work-piece by abrasion which generates substantial heat; therefore a coolant is required to keep the work-piece at a safe cool temperature so it doesn’t overheat and fall outside the tolerance range. The coolant fluid is also a safety feature for the person handling the grinder as heat may cause burns in some occasions. Coolant isn’t always required for some high-precision machines as they generate so little heat that the rise in temperature is negligible, they remove about 200 nm per pass. There are different types of grinding wheels made of different materials CBN grinding wheels are the second hardest just before diamonds they were developed as a by-product in the 50s during the manufacturing of synthetic diamond however unlike diamond it isn’t a form of carbon which opens it up to use on carbon steels whereas if diamond was used, ‘graphitization’ would occur because of the affinity of the carbon in both materials this causes rapid wear of the diamond and high temperature. These problem are not found with CBN. When it comes to coolants they are effective in preventing thermal damage since fluids remove heat from the grinding zone and they lubricate to reduce friction on the wheel and work-piece. However there are restrictions when it comes to coolants ability to cool effectively in creep-feed grinding, Shafto et al. (1975) have shown us that when it comes to creep-feed grinding water-based coolants only effectively work when the surface temperature is below the critical value of 130 °C after this temperature is reached the coolant no longer works effectively allowing the work-piece temperature to increase, because of this thermal damage occurs.

Method:

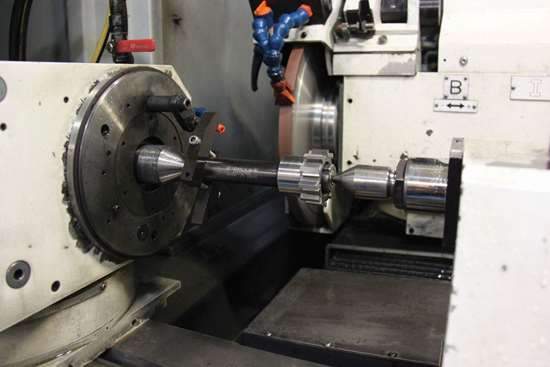

Figure 3 shows a grinding machine that’s in operation. (Probst, E. 2016)

(https://www.mmsonline.com/articles/grinding-machine-increases-tool-suppliers-production)

The lab was setup using a grinding machine similar to that of figure (x) and using suitable values of infeed rate and work-piece speed given, surface grinding was carried out and 15 different results were recorded using different samples all the pieces were then evaluated for thermal damage. During the grinding cycle the peak grinding power should be taken note of and the work piece diameter before and after the cycle should be taken down.

Theory:

a = depth of cut

θm* = critical temperature at which burn occurs

R = energy partition ratio between the wheel and the work-piece.

Approximate values of the above parameters may be obtained from the Annals of the CIRP

Where:

ec* = θm*(le/αw.Vw)0.5.λw/(0.887R.a)

Results:

|

Experimental Specific Energy (Us) |

The Equivalent Diameter |

The Depth of Cut |

Geometric Length of Contact |

True length of contact between the wheel and the work-piece |

Energy partition ratio |

Theoretical critical specific energy |

|

170.07572994 |

39.467628 |

0.0196 |

0.8795225 |

2.63856761 |

0.57847 |

129.646153 |

|

137.79573156 |

39.467628 |

0.0196 |

0.8795225 |

2.63856761 |

0.57847 |

129.646153 |

|

131.61384689 |

39.468457 |

0.016334 |

0.8029066 |

2.408719929 |

0.60053 |

130.707039 |

|

108.16318532 |

39.470944 |

0.014001 |

0.7433952 |

2.230185567 |

0.61887 |

131.812355 |

|

103.47641683 |

39.470115 |

0.012251 |

0.6953691 |

2.086107194 |

0.63448 |

132.933642 |

|

98.24007248 |

39.470115 |

0.01089 |

0.6555994 |

1.966798266 |

0.64803 |

134.044281 |

|

96.59660192 |

39.470944 |

0.009801 |

0.6219693 |

1.865907916 |

0.65995 |

135.134614 |

|

93.93941384 |

39.470944 |

0.00891 |

0.5930256 |

1.779076789 |

0.67056 |

136.20309 |

|

93.46834222 |

39.471773 |

0.008168 |

0.5677908 |

1.703372329 |

0.6801 |

137.244448 |

|

91.98347725 |

39.471773 |

0.007539 |

0.5455153 |

1.636545939 |

0.68874 |

138.261253 |

|

98.30915567 |

39.473431 |

0.007001 |

0.5256957 |

1.577086964 |

0.69663 |

139.248605 |

|

87.44468030 |

39.47426 |

0.006534 |

0.5078811 |

1.52364324 |

0.70387 |

140.212233 |

|

99.32277807 |

39.47426 |

0.005766 |

0.4770715 |

1.431214453 |

0.71675 |

142.070073 |

|

81.26932077 |

39.475089 |

0.005159 |

0.4512739 |

1.35382166 |

0.7279 |

143.836032 |

|

159.41289842 |

39.475089 |

0.005159 |

0.4512739 |

1.35382166 |

0.7279 |

143.836032 |

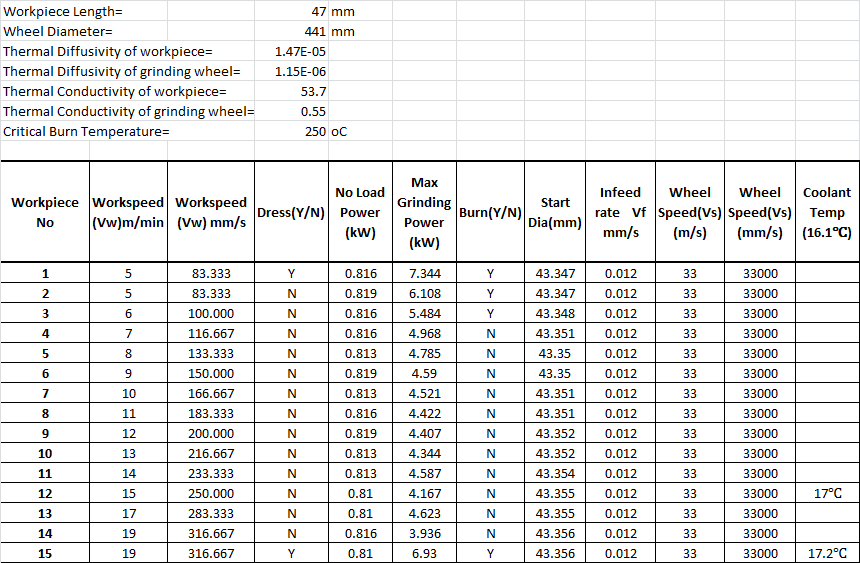

Using the above formulas and the results recorded in our table we calculated the required values for the following as shown in the table below.

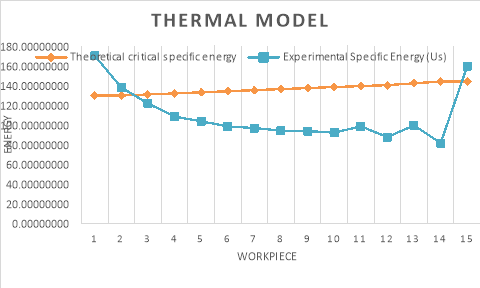

From the table we can see that thermal damaging is occurring when the experimental specific energy is above that of the theoretical critical specific energy.

Here’s a graph comparing the theoretical critical specific energy and the experimental specific energy anywhere where the blue line is above the green thermal damaging is likely to happen.

Results aren’t always 100% accurate there are always factors or things that effect our results that need to be taken into consideration, they are; tempering of the work-piece, thermal damage and residual stress. These occur due to the high temperatures the work-pieces are exposed to. The benefits of grinding are suggested by Divedi, H. (2015):

- Produces a finished piece with high dimensional accuracy

- The surface finish is approximately 10x better compared with milling and turning process of machining

- The operation is easier requires less steps

- Less energy is used making it cheaper

Discussion:

Grinding is used to produce a lot of parts that must meet a certain standard of quality for a range of reason, ultimately if a part doesn’t function like it needs to be whole structures can be compromised which rings serious health and safety alarms. Because surface temperatures rise upwards to around 1000°C plus the high temperature is the determining factor for thermal damage which may be visible to the naked eye however it can also occur on microscopic levels which will contribute to its reduced fatigue life and wear resistance and cause the part to fail before expected.

King and Hahn (1986) have summarised how to avoid thermal damage, they discussed how wheel speed effects grinding power and experimentally found that optimum wheel speed is usually within the range 8000-10000 f.p.m at either sides of this range thermal damage is more likely. However with increased speed comes increased grinding power and more heat produced this can be reduced where its stated that grinding power can be minimized by using sharper wheels of softer grades with dressing applied frequently and the proper choice of fluid type plays a big role in reducing risk of thermal damage. They go on to explain that use of oil will reduce friction in the grinding zone resulting in lower grinding power even though it possesses lower cooling properties than water however oil has a film boiling temperature of 300°C whereas water is lower so film boiling is more likely with water.

CBN grinding wheels have many advantages and the advantage that research has now confirmed is that CBN grinding wheels allow for cooler grinding. The reduced risk of thermal damage is linked with the lower grinding specific energies and the fact that a lower proportion of total grinding energy enters the work-piece when compared with an alumina wheel. The CBNs good thermal conductivity is the reason for this. (Mills, B. et al., 1996)

Conclusion:

The components produced during grinding need to be of a certain standard and live up their expected life so we need to eliminate the chance of damage whether it be from thermal damaging, softening and re-hardening of surface materials or the residual stress. To avoid this we need to prevent film boiling by reducing the heat that the work-piece is exposed to this can also be achieved by removing the heat more efficiently. There are different ways this can be achieved. These are:

- Use CBN wheels because of the high thermal conductivity.

- When suitable use oil as a coolant.

- Make sure work and wheel speed is at optimum settings

- Sharper wheels of softer grades.

- Coarse dressing as opposed to fine dressing.

References:

- https://link.springer.com/article/10.1007%2FBF01186926

- Neailley, K., 1988, “Surface Integrity of Machined Components — Microstructural Aspects,” Metals and Materials, Vol. 4, No. 2. Pp.93-96.

- Shafto, G.R., Howes, ID., and Andrew, C., 1975, “Thermal Aspects of Creep-feed Grinding,” Proceedings of the 16th International MTDR Conference, Manchester UK

- http://www.hkdivedi.com/2015/12/applications-and-advantages-of-grinding.html

- https://www.slideshare.net/lalukumar56027/l9-grinding2012 (pic)

- King, R.l., and Hahn, R.S., 1986, Modern Grinding Technology, Chapman and Hall, New York, London

- https://www.mmsonline.com/articles/grinding-machine-increases-tool-suppliers-production (pic)

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal