Operational Analysis of BP

| ✅ Paper Type: Free Essay | ✅ Subject: Engineering |

| ✅ Wordcount: 1780 words | ✅ Published: 30 Aug 2017 |

P1 Describe the different sectors in which engineering companies operate and the function that they carry out in that sector.

Task1

a)Research and describe the function / operation of one of each engineering companies that you judge to work within the Primary, Secondary, Tertiary and Quaternary sectors.

Where applicable, state any products that these companies manufacture.

Bp

- Primary – BP is basically located in all the sectors. Primary sector basically involves the extraction of raw materials. These raw materials include iron ore, trees, unprocessed coal, and oil. The primary sector is also referred to as the extractive production. BP is involved in this sector as it extracts its own raw materials which include crude oil and gas. Extraction is of their oil is mainly done in the Gulf of Mexico which include Atlantis, Na Kika, Thunder Horse and Mad Dog and on land their oil drilling rigs are in many places including 48 states on the United States and one of them is Alaska. In its involvement in the raw material extraction, BP between 2013 and 2015 its average daily production or extraction raised from 189,000 barrels of oil equivalent to 249,000. After crude oil and gas has been extracted the next step is to transport it to a refinery plant and create known fuels of today and that will commence the next stage which is the secondary sector. BP is involved in all the sectors meaning that it extracts its own raw materials, refine its own oil to make products and then distribute it and it does its own research to improve its refining methods to make its products of great quality.

Oil rigs in the Gulf of Mexico operated by BP

.

- Secondary – as BP is involved in all the sectors as mentioned above, it refines its own crude oil to make many products that include fuel for many vehicles including aircrafts, gas used in homes and many more. The secondary sector basically involves the turning of raw materials into finished products or goods which will be used by other businesses. The main BP refinery plant is in Cherry Point, Wash.; Whiting, Ind.; and Toledo, Ohio as per BP website and they refine up to 744 000 barrels of oil every day. In this sector, they produce a wide range of products which include fuels like petrol and diesel, petrochemicals and lubricants which are then used to power up vehicles of all sorts. The end products of this sector are sold to aircraft owners as jet fuel, motor vehicle fuel and vehicle lubricates such as motor oil.

BP refinery plants

- Tertiary – this sector includes the distribution of the finished products or in other words the provision of services and goods to customers like for example jet fuel to companies like Boeing. To distribute its products throughout the whole world, BP has created fuel stations throughout the world which sell petrol and diesel. It also sells gas. It also supplies its products through independent jobbers and dealer wholesales and franchised retail sites as per the BP website.

- Quaternary – this sector basically involves research and development within a company. The quaternary sector is based on knowledge and skill and scientific research to improve efficiency or the quality of the products being created. With BP, there is a sector which is always developing and researching technologies to make its operations safer and efficient and explore and discover new resources to use. As per the BP website, it tests, uses, and creates innovative technologies at its refinery plants and in its fuel business to make the product of quality and to make sure that it is safe to use. It is also researching ways to avoid oil spills that will destroy the natural environment thereby making the world a safer place.

Shell

- Primary– as with BP, shell is also an oil based company that is involved in all sectors. In the primary sector, it extracts its own crude oil mainly in the North Sea. It extracts crude oil as well as gas and because it mainly operates in the North Sea, they constantly face challenges extracting that oil. In this sector shell uses extended reach drilling technology that allows it to work in places with high pressure as where the crude oil and gas is located since the fossils where made in high pressure conditions. Their first major oil discovery was in 1971 and was in Brent field which then started producing oil in 1976. Its first gas field was in Leman field and it was in 1966. Shell operates about 33 offshore oil extraction plants and about 65 interests in the North Sea as per the shell website.

- Secondary- after the extraction has been done like for example offshore, the raw materials are then transferred to onshore for processing. Its transported by pipeline most of it. When it arrives, the oil is refined and processed using a process called fractional distillation. Also, the oil enters the globally traded crude oil market and the finished products such as petrol and diesel that is put into cars, aviation, and marine fuel and lubricants and plastics and chemicals are then distributed in the tertiary sector. With gas, it is processed on shell’s 3 main gas plants which include St Fergus, Mossmoran and Bacton and they produce about 35% of the UK gas as per the shell website.

- Tertiary – after the secondary stage has been finished that it the products have been made such as fuel, lubricants and products like plastic, the next stage is to distribute them to potential customers which include large companies like for example involved in aviation business and motor vehicle. Also, SHELL has its own fuel stations across the world so that it can distribute its fuel to the people. As a large company shell has small franchises that only specializes in the distribution sector like for example some fuel stations maybe franchises and it is another way of distributing its fuel to the world.

- Quaternary – as a large company, Shell is always looking or researching for new technologies to improve its raw materials extraction, its production. It’s looking for ways to make the whole process efficient. It’s also developing technologies to cope with the deal with challenging environment like high pressure environment like in the North Sea. It’s also researching in the field of advanced imaging to improve production. This include the research of 3D seismic images to help see the flow pattern of oil underground. This is all done to boost the oil production to meet the demand of the growing population.

TATA industries

- Primary- TATA steel mainly operates in India and its 3 main materials it extracts are iron ore, chromite, and coal. Iron ore and coal are the main raw materials needed for the creation of steel. The company started mining these raw materials in 1903 as per their own website. The mining sites are in Noamundi, Joda and Katamati in the states of Jharkhand and Odisha. Its coal mines are in Jharia & West Bokaro, in the state of Jharkhand. These raw materials are then used to make steel that is then transported to its vehicle making plant to make motor vehicles and other machines.

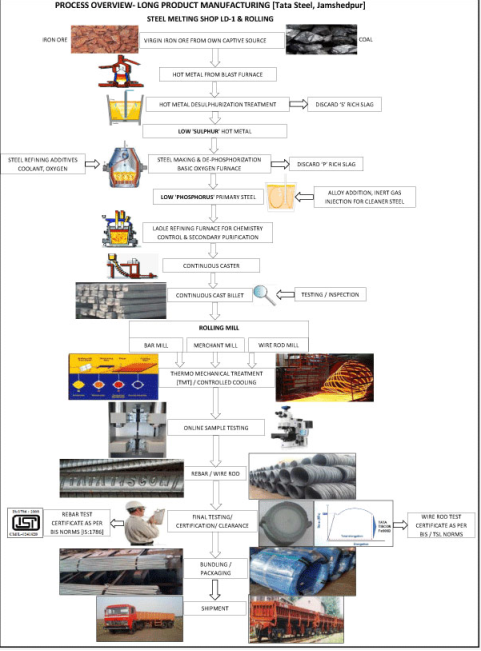

- Secondary- the whole secondary process is explained through the picture below. from how the iron ore is melted and the processes it goes for steel to be produced. Also, as mentioned above this process involves the transformation of raw materials to finished goods and products. In this sector is where the steel production is done by using iron ore and coal. Iron ore is smelted and the iron is separated from the ore. After that the iron is then further re melted and addictive’s are added such as coke and limestone in the furnace. After this process steel is produced. After steel, has been made it is used to make cars in the land rover and jaguar factories. Besides making cars, it also makes Gears, engines, motors, hydraulic systems, power generation.

- Tertiary – after the manufacturing process, the next stage is to distribute and sell the finished goods to the consumers. The company has its own dealers that sells the famous jaguar and range rover cars. Besides cars it also sells car gears and engines to other manufactures. It also sells motors and generators. So, the company has its own dealerships as well as other franchises that will sell their products on their behalf.

- Quaternary – the company has a division that specializes in research and development and production of advanced technologies. The company is always looking for new technologies to make mining safe and efficient. Also, its researching ways to make cars that produce less carbon footprints. Also, its producing technology or software that estimates the volume of coal in every seam and the quality.

Information and pictures extracted from https://uk.pinterest.com/annmaireesaward/bp/

http://www.shell.co.uk/energy-and-innovation/meeting-todays-demands/finding-oil-and-gas.html

http://www.tatasteelindia.com/products-and-processes/raw-materials.asp

P2 Describe the organisational types of three given engineering companies

Task2

From the companies, you have chosen above;

- Give a brief outline for the companies and state the sort of organisational type (the type of business organisation) they may have? (For example: sole traders, partnerships, companies, franchises).

Shell is a franchise

- Describe the nature of their business.

- Describe the range of products that they offer and the engineering functions they carry out.

- State the kind of Organisational structures they have? (For example: Line Organisational Structure, Hierarchical structures).

- Explain why an Organisation needs a Structure?

P3Outline how information flows through an engineering company in relation to an engineering activity

Task3

- Using the company you work in, draw up an organisational chart that shows the line of command in the company. Select a product that the company maintains.

- With reference to the above product, describe with aid of a flow chart how information is passed in an effective manner between the people responsible for its maintenance.

M1 explain how improvements in information flow could enhance the functional activities of an engineering company

Task4

- Explain how business improvement techniques such as 5S/5C (Sort, Set-In-Order, Shine, Standardise and Sustain) facilitate information flow.

D1 Evaluate the information flow through an engineering company in relation to an engineering activity

Task5.

Evaluate the effectiveness of how information is passed for the given company. Your evaluation should include as a minimum;

- The advantages and disadvantages of the process flow.

- Time it takes to complete the order against customer needs.

- Identify problems with the system.

- Describe why Lean Manufacturing has become an important philosophy to manufacturing industry and why techniques such as Just in Time (JIT), Kanban and 5S are so valued.

- You need to write to your manager explaining how you think information flow and communications can be improved.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal