Dounreay power station: Decommissioning, Waste Management and Site Remediation

| ✅ Paper Type: Free Essay | ✅ Subject: Engineering |

| ✅ Wordcount: 7437 words | ✅ Published: 23 Sep 2019 |

|

Dounreay power station: Decommissioning, Waste Management and Site Remediation Decommissioning, Waste Management and Site Remediation |

Abstract Report researching Dounreay relating to Legislation & Regulations, Planning implications, Techniques & Methods and Issues & Impacts. |

Introduction

Dounreay Site

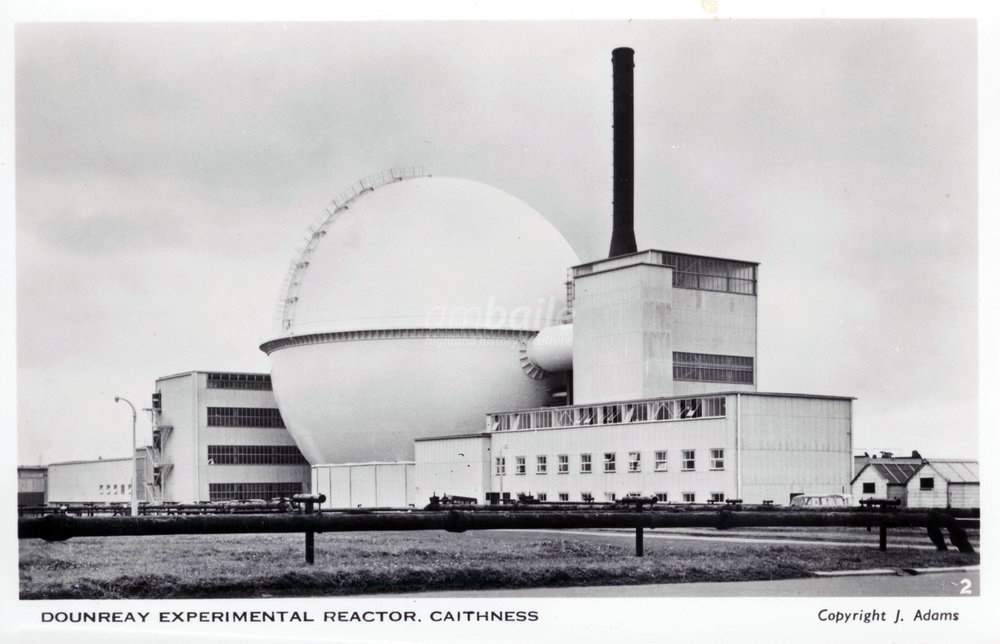

Figure 1 (Ambaile.org.uk, 2018)

Construction of the Dounreay power station began in 1955 on the north coast of Scotland in Caithness. Caithness is the most northerly county in Scotland and this was an important factor when choosing the site. Mainly for safety reasons, in case of explosion. The most prominent feature of the site was the sphere-shaped steel structure which at its highest point measured 139ft.

The Dounreay site was originally the base of a World War II airfield. The site then went on to house three nuclear reactors. Two Fast Breeder Reactors and a thermal research reactor.

When it was constructed Dounreay was at the centre of the UK’s fast reactor research and development. Here scientists and engineers experimented with plutonium and uranium among other metals to gather information in pursuit of being able to generate electricity using the advanced type of nuclear reactor. Research went on for nearly 40 years ceasing to operate in 1994.

The arrival of the plant came as a welcomed boost to the local economy. The town had been in decline for some time. The population of Thurso tripled, and the plant also provided a high employment rate.

Now the site is one of the largest clean-up and demolition projects. The plan is to return the site as close as possible to its original state. The work being undertaken is funded by the Nuclear Decommissioning Authority. The Office for Nuclear Regulation (ONR) are responsible for monitoring the clean-up where regular inspections are carried out in line with health and safety standards. Decommissioning is due to be complete by 2022-2025 which is an improvement on original plans which would have taken until 2038. This reduced time frame is expected to save over £1 billion.

The site still provides a high level of employment even in its decommissioning phase.

www.dark-tourism.com/index.php/15-countries/individual-chapters/1152-dounreay-exhibition-thurso#b

Decommissioning

Within the nuclear industry decommissioning is the dismantling of facilities and structures that have reached the end of their lives. The term ‘Clean-Up’ refers to the treating or removal of contamination from around the site. The final stages of Decommission and Clean Up will involve managing large amounts of radioactive waste. High level waste will be stored securely but most waste from decommissioning will only have low levels of radioactivity. This will commonly include demolition rubble, scrap metal, foundations, drains and pipelines, or soil. All needing to be disposed of safely.

Legislation & Regulations

Many of the Regulations and legislation that are in place covering decommissioning will apply to the whole of the UK. However, as Dounreay is in Scotland some of the Regulations and Legislation may differ or be governed by a different body, which will be highlight below. Consideration must be given to a lot of regulations and legislation, but I will draw attention to the ones of major importance.

Before any work on decommissioning and Clean-Up operations can commence it must first take into account;

- all relevant environmental legislation

- relevant government policy

- statutory guidance published by government

- other guidance issued under the Radioactive Substances Regulation (RSR) regime

- relevant guidance on regulation of non-radioactive substances and protection of the environment

The Environmental Agency (EA), Natural Resources Wales (NRW), and the Scottish Environment Protection Agency (SEPA) have jointly produced a publication to set out guidance for nuclear sites. The guidance for nuclear sites is given when operators are planning work on decommissioning and clean-up projects. The aim is to make sure that operators are working in in a way that is safe for the environment and the public. This guidance address area such as; how they leave the site, and how they manage radioactive waste. Operators are required to produce a waste management plan (WMP), produce a site-wide environmental safety case (SWESC), make sure the condition of the site meets standards for protection of people and the environment, now and in the future. Operators are also encouraged to meet obligations under the management of non-radioactive waste. Early engagement with the local communities and public as well as regulators is advised. The overall goal is to ensure that the site is brought to a condition so that it can released from the Radioactive Substances Regulation (RSR), in a way that protects the health and interests of the public and the environment throughout the period of regulation and afterwards.

The guidance has been prepared taking into consideration the ‘Policy on Decommissioning of the UK Nuclear Industry’s Facilities (2004)’ and the ‘Policy for the Long-Term Management of Solid Low-Level Radioactive Waste in the United Kingdom (Defra, 2007)’. For higher level waste the ‘Radioactive Waste Management Cases (RWMCs) (ONR et al., 2015)’ need to be produced. The NS_GRA (EA et al., 2009) will apply to any near surface radioactive waste disposal facility on-site and this will also require its own Environmental Safety Case (ESC)

https://www.sepa.org.uk/media/365893/2018-07-17-grr-publication-v1-0.pdf

Scottish Environment Protection Agency (SEPA) regulate the management of radioactive substances in Scotland under the Environmental Authorisations (Scotland) Regulations 2018 (EA(S)R. There are four different types of authorisation under the EA(S)R which include:

- General Binding Rules GBRs)

- Notification

- Registration

- Permit

SEPA are the environmental regulators for Scotland. They are responsible for issuing permits and registration of the nuclear industry which include conditions on how radioactive substances are managed. SEPA are responsible for enforcing The Regulatory Reform (Scotland) Act,it is in place to protect the environment and promote environmental and social success as well as economic growth. SEPA works jointly with the NDA to manage Decommissioning and Clean-Up in Scotland.

The Office of Nuclear Regulation (ONR) are responsible for assessing environmental impacts of decommissioning nuclear power stations and reactors before work commences. Using the ‘Nuclear Reactors (Environmental Impact Assessment for Decommissioning) Regulations 1999 (EIADR)’ Operators must apply for consent before starting a decommissioning project, submitting a supporting Environmental Statement. They operate Nuclear site safety under the ‘Nuclear Installations Act 1965 (NIA 65)’ they are also responsible for granting nuclear site licences to operators. Health Safety Environment (HSE) decided that EIADR does not apply to Dounreay as work on Decommissioning had started before it was introduced in 1999 but it is still within scope of Regulation 13 of Environmental Impact Assessment for Decommissioning) Regulations (EIADR).

Nuclear Decommissioning Authority (NDA) are responsible for overseeing decommissioning in the UK and ensure the safe and efficient clean-up. It is responsible for the safe management of radioactive and non-radioactive waste products, implementing policy on the long-term management of nuclear waste and developing strategy for Low Level Waste. It is an executive non-departmental public body sponsored by the Department for Business, Energy & Industrial Strategy supported by Dounreay, Low Level Waste Repository Ltd, Magnox Ltd, Radioactive Waste Management and Sellafield. The body was created through the Energy Act 2004. In Scotland the NDA are responsible to Scottish ministers. The NDA are also responsible for establishing an approach, allocating budgets, setting targets and monitoring progress.

The Environment Agency, Natural Resources Wales, and the Scottish Environment Protection Agency have a duty to protect members of the public and the environment from radioactive substances regulating the disposal of radioactive waste from nuclear sites under the ‘Radioactive Substances Act 1993 (RSA 93)’ for Scotland.

Environmental Authorisations (Scotland) Regulations 2018 (EA(S)Rare responsible for delivering the framework to protect water, waste management, radioactive substances and pollution prevention and control.

The European Commission must also be consulted, and the operator would need to submit a plan for the disposal of radioactive waste to comply to ‘Article 37 of the Euratom Treaty (European Atomic Energy Community (1957)’ Where it would be assed to see if the project was likely to affect another member state in the way of radiological contamination. The Department for Business, Energy and Industrial Strategy (BEIS) can be consulted if there is any doubt about the application of Article 37.

The Department for Environment, Food and Rural Affairs (Defra) is a Government Department and are responsible for environmental protection and ensuring the nation recovers quickly in the event of a chemical, biological, radiological and nuclear incident.

International Atomic Energy Agency (IAEA 2012) is responsible for assisting research, development and practical application of Atomic Energy for peaceful uses globally. It oversees safeguarding arrangements and inspection of nuclear sites.

Health and Safety Executive (HSE) are responsible for the prevention of work-related death, injury or illness in Great Britain. The Health and Safety at Work etc Act 1974 is in place to cover health and safety in Great Britain. Within the nuclear sector operators are required to comply with this Act.

“Operators of nuclear facilities in Great Britain, like their counterparts in

other industries and places of work in general, are required to comply

with the HSW Act and its relevant statutory provisions. The HSW Act places a fundamental duty on employers to ensure, so far as is reasonably practicable, the health, safety and welfare at work of all their employees. It also imposes a duty on employers to ensure, so

far as is reasonably practicable, that persons not in their employment

are not exposed to risks to their health or safety as a result of the activities undertaken.”

(https://onedrive.live.com/?cid=1102AD6316A0CD51&id=1102AD6316A0CD51%21972&parId=1102AD6316A0CD51%21459&o=OneUp)

Office of Nuclear Security (OCNS)

It is strongly advised that proposals for work on a Decommission or Clean-Up project are discussed with the local planning Authorities. Some work may require planning permission under the ‘Town and Country Planning (Scotland) Act 1997’.

‘Water Environment (Controlled Activities) (Scotland) Regulations 2011’ is in place to make sure that the wider water environment is protected from the adverse effects of water abstraction, water impoundment, water course engineering and discharges to surface water. The Groundwater Directive (EC 2006) must also be taken into account. Management is also needed for the prevention of contamination of ground and groundwater by radioactive substances. The ‘Regulatory Expectations for Successful Land Quality Management at Nuclear Licensed Sites’ (ONR, NRW, SEPA & EA 2014) and ‘Statement of Common Understanding’ on the disposal of radioactive waste on nuclear sites by deposit or burial (EA, SEPA, NRW & ONR, 2016)’ should be referred to.

Operators should also consult the ‘Disposal of radioactive waste by deposit or burial: Joint Regulators’ Statement of Common Understanding’ (EA, SEPA, NRW & ONR, 2016)’ and ‘Near-surface Disposal Facilities on Land for Solid Radioactive Wastes: Guidance on Requirements for Authorisation’ (NS-GRA) (EA et al., 2009).

Radioactive waste is subject to different legislation to that for non-radioactive waste RSR legislation in the UK transposes Directive 2013/59/Euratom (EC, 2013) whose primary aim is the protection of people from ionising radiation. UK legislation governing non-radioactive waste (directive waste) transposes the Waste Framework Directive.

The Framework Directive addresses the collection, transport, recovery and disposal of directive waste and makes sure that it is recovered and disposed of without endangerment to public health or causing harm to the environment.

The international Radiation Protection Framework has legislative force throughout the European Union.

Measures of radiation and Harm managed by the ICRP (2007)

Radioactive Substances Act 1193 (RSA 93) and the Radioactive Substances (Basic Safety Standards) (Scotland) Direction 2000

.

- The Carriage of Dangerous Goods and Use of Transportable Pressure

Equipment Regulations 2009 (as amended)

- Control of Major Accident Hazards Regulations 1999

- Dangerous Substances and Explosive Atmospheres Regulations 2002

- The Energy Act 2013

Part 3 of The Energy Act 2013 deals with Nuclear Regulation. It

establishes ONR as a statutory corporation. Amongst other things,

it makes the ONR responsible for the enforcement of statutory

provisions which are ’relevant statutory provisions’ for the purposes

of that Act. These provisions include sections 1; 3-6; 22 and 24A of

NIA65 as well as the Nuclear Industries Security Regulations 2003

(NISR) and the Carriage of Dangerous Goods (CDG) 2009 as they

apply to the carriage of radioactive material for civil purposes. It refers

throughout to the ‘appropriate national authority’ which in England,

Wales and Scotland are the ONR. In relation to Northern Ireland, it is the

Secretary of State.

- Management of Health and Safety at Work Regulations 1999

- The Nuclear Installations Act 1965/69 as amended

The Nuclear Installations Act 1965 (NIA 1965) establishes three main elements with regard to nuclear installations: the requirement to be licensed, the exercise of control through the issue of permit over certain processes, and the provision of a legal regime regarding the liabilities of the licensee to third parties.

- Radiation (Emergency Preparedness and Public Information) Regulations 2001

- The Nuclear Industries Security Regulations 2003 (as amended) (NISR)

- Radiation (Emergency Preparedness and Public Information) Regulations 2001 (REPPIR).

- Radiological Protection Act 1970

- Ionising Radiations Regulations 1985

- Environmental Protection Act 1990

- Radioactive Substances Act 1993

- Environment Act 1995

- Radioactive Material (Road Transport) (Great Britain) Regulations 1996

- Packaging, Labelling and Carriage of

- Environmental Impact Assessment for Decommissioning Regulations 1993

- Health Protection Agency Act 2004

- Health and Social Care Act 2012

- Town and Country Planning (Environmental Impact Assessment) Regulations 2017 (TCP 2017).

- Radioactive Material by Rail Regulations 1996

Planning Implications

The cost of decommissioning is set out with a Nuclear Provision which aims to estimate how much it will cost to clean up all the UK’s nuclear sites. The estimate includes decommissioning, dismantling and demolishing the buildings, managing and disposing of all waste and remediation of land. The annual cost for decommissioning is currently around £3.146 billion with Dounreay accounting for 1.9% of this figure. Of the £3.146, £2.967 billion is coming from government funding. It is expected that the costs will continue for the 120 years costing £121 billion but there is some level of uncertainty and costs could be anywhere from £99 billion to 225 billion.

https://www.gov.uk/government/publications/nuclear-provision-explaining-the-cost-of-cleaning-up-britains-nuclear-legacy/nuclear-provision-explaining-the-cost-of-cleaning-up-britains-nuclear-legacy

In 2000 the Dounreay Site Restoration Plan was set out with an expected 60-year timeframe costing £4.3 billion. In 2007 a new plan was agreed with an expected 25-year timeframe costing around £2.9 billion. And then the year after that the timeframe was reduced to 17 years costing £2.6 billion. It is estimated that the annual figure for 2018/2019 is £192 million. It is the responsibility of Dounreay Site Restoration Ltd (DSRL) for the Clean-Up and demolition of the Fast Reactor research and development. The DSRL are owned by Cavendish Dounreay partnership and are funded by the NDA.

Funding of the NDA is provided publicly through the Department for Business, Energy and Industrial Strategy (BEIS) with Parliament voting on total planned expenditure. The NDA also has funding coming from their commercial activities, which include transportation and management of spent nuclear fuels.

Dounreay Stakeholder Group is an independent body that provide public scrutiny of the Dounreay Site. This helps provide communication between the Site operators and the NDA and local stakeholders. Other groups who may have an interest are:

- Caithness West Community Council

- Committee on Medical Aspects of Radiation in the Environment

- Copeland Borough Council

- Cumbria County Council

- Environment Agency

- Hampshire County Council

- Health Protection Agency

- Highland Council

- NHS Highland

- Nuclear Decommissioning Authority

- Orkney Island Council

- Particles Retrieval Advisory Group (Dounreay)

- Scottish Natural Heritage

- Scottish Water

- Shetland Islands Council

http://dounreaystakeholdergroup.org/files/downloads/download2758.pdf

https://www.sepa.org.uk/media/116693/dounreay-radioactive-waste-disposal-consultation-document.pdf

The Dounreay Site employs over 1000 people in house with plans to reduce jobs and redundancies packages being offered as the site is coming to the end of its lifespan. Dounreay Site has announced that it committed to the workforce and the long-term employment.

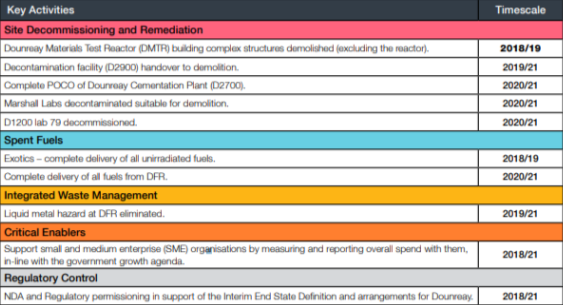

Figure 2

Phase 1 of decommissioning at Dounreay started in 2007

The Prototype Fast Reactor (PFR) was designed to test fuel, coolant and equipment on a scale appropriate to commercial electricity station. It ran from 1974 until 1994. It was decided by the UK government to shut the programme down and Decommissioning started in 2016 Fuels and materials have been transferred to Sellafield for safe cost-effective storage. The waste of Highly enriched Uranium has been transported to the United States. With all fuel being in either long-term storage or shipped of site by 2025.

The NDA funds decommissioning at Dounreay.

Within Decommissioning the stages are defined in facilitates of life:

- Operational phase.

- Shut-down transition phase (defueling & post operational clear-out known as POCO).

- Preparation for safe enclosure.

- Safe enclosure period.

- Final dismantling.

Dounreay staged planning started in 2005 initiating Phase 1, where planning permission was granted for intermediate level waste (ILW) cementation plant and store and an extension to the existing ILW store. Phase 1 was completed in 2012 and the second phase commenced. This phase addresses the provision of further fuel and waste management. It will include headworks for the shaft and silo of the waste treatment plant. It will also include the storage of the demolition rubble which will be later used in landscaping. This phase will start decommissioning of redundant plants and demolition of some structures. Phase 2 ended in 2018 marking the start of Phase 3. In Phase 3 it is planned that final demolitions will happen with the removal of rubble and debris being collected and being re-used for landscaping. The only remaining buildings will be the ILW stores and LLW disposal facility at the End point. This phase is expected to be complete in 2025.

The UK’s total and expected radioactive waste is estimated to be at around 4.5 million cubic meters. This includes waste from planned operations and existing operations. All this waste needs to be eventually stored in an underground repository, but this isn’t expected to be ready until 2040. Most of the nuclear waste is produced comes from research and development of nuclear technology. With most of it coming from nuclear power stations. The radioactive waste is stored in concrete containers once it has been converted into solid form. For Low Level Waste the waste must be compacted to minimise its volume, it is then placed into metal containers and then placed in concrete lined vaults. For Intermediate-level waste it must be encapsulated in cement-based materials within a 500 litre stainless steel drums with larger items being packaged in higher capacity stainless steel or concrete boxes. There is no existing disposal route for ILW, the waste is stored in drums, tanks, vaults and silos on site. Sometimes when needed it transported off site to a specialised facility. High-Level liquid waste needs to vitrificated to incorporate it into borosilicate glass. It is then poured into stainless steel canisters and the lid is welded on. There is no current route for disposal of HLW, the waste needs to be stored for 50 years before it can be disposed. This allow the heat to diminish before it can be transported and disposed of.

The waste hierarchy

Figure 3 (Ukinventory.nda.gov.uk, 2018)

The waste hierarchy is in place to encourage new approaches towards LLW to make waste management more sustainable. The idea is to prevent as much waste being produced as possible and if it isn’t possible then re-cycling or re-using would be an option. Before recycling can happen, the waste must have first been decontaminated. Incineration would also be another option, leaving disposal as a last resort.

Dounreay houses an Intermediate Level Waste packaging plant with most waste being stored at Sellafield. It is transported there by train or by road, but route is not made common knowledge due to security risks.

Plans to deal with the Clean-up of Dounreay include waste management. The above ground waste store is expected to be processed and packaged within the next three years. Work has also begun to deal with the waste produced by the prototype fast reactor. This involves turning the liquid into a solid which is achieved through mixing it with cement ash and lime. Once mixed it will be poured into drums before it solidifies where it will be stored long-term. All Prototype fast reactor liquid waste known as Raffinate is expected to be processed in the next five years. Dounreay also plans to build a new LLW facility where it can treat, package and emplace waste.

Waste Management Policy

The Scottish Government’s policy on Scotland’s Higher Activity Radioactive Waste (2011) says:

“The Scottish Government Policy is that the long-term management of higher activity radioactive waste, should be in near-surface facilities. Facilities should be located as near to

the site where the waste is produced as possible. Developers will need to demonstrate how the facilities will be monitored and how waste packages, or waste, could be retrieved. All long-term waste management options will be subject to robust regulatory requirements.”

(PDF-Supplementary Guidance Dounreay Planning Framework 2)

Site End State Assumption

The site at Dounreay is planned to be de-licensed in 2033 which will be the Final End Point. At this stage it is expected that the site will have been restored to a point where it can be used for other purposes. Although some infrastructure will be left in-situ and residual contamination will remain. The PFR will be cleaned out of residual coolant once the remaining heels have been drained, The PFR is planned to be demolished in 2025 once all the reactor internals have been reduced into suitable waste packages.

The vision for the end of use of the Dounreay site is develop the land for employment issues, with off shore renewables being a favourable option. Other potential options for use of the land will be regularly reviewed with any changes being compatible with any ongoing regulatory requirements, including SEPA’s environmental permits.

Techniques & Methods

Decontamination to remove contamination from any surfaces of the facilities or equipment. This can be performed in a number of different ways. This can include washing, chemical, electrochemical action, mechanical cleaning. The aim is to keep radiation exposure to a minimum, recover equipment and materials. To reduce the amount of equipment and materials that need to be stored or disposed of in disposal facilities. To restore the site back (or as close) to its original state. To remove any loose radioactive contaminants and fix any other bits ready for the protective storage. To reduce the amount of radioactive material being stored to protect the health and safety of the public.

Loose contaminants can be cleaned from floors and walls with water rinsing but then this possess the problem of the pipes and system being treated for contamination.

Chemical Decontamination is used to remove contamination from base metals. Diluted Chemicals reagents are used in contact with the contaminated area. It works by dissolving the layer of contamination from the metal and also dissolves some of the base metal itself. This is fine as long as the corrosion does not completely penetrate the metal. And if the metal is not planned for re-use then it doesn’t matter at all.

The benefits of using Chemical Decontamination are its effectiveness at reducing the radioactivity of large surface areas, complex geometries as well as in and outside pipes. It is a relatively inexpensive method that is well established within the nuclear industry. There is little risk of contamination becoming airborne. And can almost completely remove all radionuclides from surfaces. If carried out well the item may be decontaminated up to releasable levels.

The Disadvantages of using Chemical Decontamination are that they require efficient recycling of reactive chemicals. If insufficient recycling of decontamination products happens then this will result in a build-up of secondary wastes which are extremely costly and difficult to treat. The problems can occur when the surface is rinsed with water causing recontamination. Also, it may not be very effective in treating internal/hidden areas and can’t be used on porous surfaces. Risks are possible when handling toxic and corrosive reagents.

Mechanical decontamination are physical techniques, it can include washing, swapping, foaming agents and latex-peelable coatings. And can be used on any surface achieving good results. Techniques like Spalling or Scarifying use abrasive blasting or grinding on concrete and plastic structural surfaces. This method has proved very successful at achieving a very high decontamination factor. One of the set backs are that when using a wet abrasive system water droplets and dust are created and these might be difficult to treat. Great care needs to be taken so that contamination is not introduced into the material surface, this is known as the hammering effect. Another downfall of mechanical decontamination is that it cannot be performed on complex surface.

Melting Decontamination is usually the last step in the decontamination process performed after say, chemical decontamination has already been completed. It works by homogenising (breaking up molecules) many radionuclides from the material. It is a great benefit for dealing with complex parts with inaccessible surfaces that need to be decontaminated. It is also able to decontaminate radionuclides within the slag and filter dust from the remaining from the melting process. It is a great option for dealing with large bulky components that otherwise would take up a lot of space within a repository. The scrap metal produced is highly valuable and can be recycled.

Demolition Methods used in decommissioning consist of three main methods;

- Immediate Dismantling, Safe Enclosure and Entombment. Immediate Dismantling happens soon after the facility is closed-down usually within a few months or years. Once the equipment, structures and parts containing contamination have been removed. Immediate dismantling allows the site to be re-used.

- Safe Enclosure is where dismantling is deferred usually for 40-60 years. The site is monitored while radioactive decay is allowed to happen. Once the decay is complete the site can begin to be dismantled and building can be decontaminated. There is a risk with this method as regulatory change could increase costs unpredictably.

- Entombment is where is any radioactive contaminants are encased permanently on site within a concrete. The site will be monitored once radioactivity levels reach a point where they are safe for restricted release.

Each approach has its advantages and disadvantages, Immediate dismantling ensures that the burden of decommissioning is not passed down to future generations. It also makes use of the experience and skills of the operating staff already working on the site. Safe Enclosure has the benefit of radioactive residue being reduced meaning less exposure to radiation hazards. The expected mechanical technique improvements could lead to a reduction in costs and hazards. Entombment has the benefit that when it comes to the decommissioning of site the radioactive risks are no longer of concern.

http://www.world-nuclear.org/information-library/nuclear-fuel-cycle/nuclear-wastes/decommissioning-nuclear-facilities.aspx

Electro-chemical decontamination is the process used to treat contaminated item by bathing item in an electrolyte bath or applying a pad over the surface of the item that needs to be decontaminated. An electrical field assists the chemical decontamination, the electric current causes the anodic dissolution and removal of metal and oxide layers from the component. You can only apply this process to a conducting surface, but they are a highly effective at decontamination.

Unfortunately, there are limitations to its use. When being immersed into a bath there is a maximum size that will fit. Also, when a pad is being used there may not be enough clearance to access all area due to the geometry of the item being treated. This makes it impractical for many industrial decontamination projects as pipes, valves and pumps cannot be accessed completely. Also, the exposure to workers is increased when using the bathing method. The electrochemical method can only be used on materials that are conductive eg. Iron-based alloys, copper, aluminium, lead and molybdenum. And the material must not have any oil, grease, paint, coatings or oxides present. These must be removed before this process is attempted.

New decontamination mythologies are being developed that will incorporate chemical, electrochemical, biological, mechanical, laser and sonic mythologies.

https://www.oecd-nea.org/rwm/reports/1999/decontec.pdf

Bioremediation is a process used to treat radioactive waste, where microorganisms interact with metal ions to remove or neutralize pollutants from a contaminated site. These organisms effectively degrade pollutants at rapid rates. It can be used to treat contaminated ground water and soil to get the site back to a usable state. It can be done via either in-situ or ex-situ method. The benefits of In-situ bioremediation are that everything is left in place. The organisms are added to environment to support bioremediation also known as bioaugmentation. Ex-situ involves taking the contaminated soil or water from the site to be treated. The process aims to improve clean-uptime and cost of the site.

Unfortunately, when the organisms are introduced to the site, they rarely survive more than a couple of weeks and can establish a niche in the environment. The organisms may be strongly absorbed by the solid surfaces making it difficult to transport them to the site. There is still very little that is known about Bioremediation, but more research is being done. There is resistance from regulators and the public about the use of Bioremediation and some remain fearful of the release of genetically engineered organisms being released into the environment.

https://www.sciencedirect.com/topics/earth-and-planetary-sciences/bioaugmentation

Dounreay has opted for tried and tested methods as well as innovative techniques in their plan to decommission the plant. For the Prototype Fast Reactor Post-Operative Clean-Out was undertaken following its closure. The main task involved removing the fuel which significantly reduced the immediate hazard risks and maintenance requirements. There are significant pre-works that need to be undertaken before physical decommissioning can happen. Firstly, A HEPA filtered ventilation needs to be installed. The monitoring and sampling systems need to upgrade for atmospheric discharges. Also, Environmental monitoring systems need to be upgraded. waste handling plants need to be built for the solid and liquid waste. The electrical supplies need to be upgraded. The biggest decommissioning task of the PFR is the disposal of 1500 tonnes liquid metal.

https://www.gov.uk/government/publications/dounreay-credible-options

Issues & Impacts

As a nuclear site nears the end of its life and starts to enter into decommissioning phase, lots of changes can be observed that may have an effect of social and economic aspects. One possible change could be that the site ownership could change hands. Another could be delays in work begging in the decommissioning process. These delays could be caused by political, funding or licencing issues. This may have a negative effect on the workforce, effect staff morale, motivation and loyalty. Many of these issues can cause uncertainty about their future, affecting staff stress levels which will be felt by their families as well. Concerns about finances may be an issue if jobs are lost, this could also raise concerns about pensions, social security and other benefits. The skill set that is required during the clean-up might not be recruited from the original workers.

The local community will also feel the effects of a site shut down too with most people in remote areas relying on the site for employment. The local infrastructure will also be significantly affected as will the local economy. With many people now being on lower incomes after possibly choosing a redundancy package. People may even be forced to move out of the area to find work. This could lead to a surplus of property in the area resulting in a fall in property value. Creating a negative image of the area. The increased traffic caused by the clean-up could cause damage to the roads local amenities may be withdrawn and investment for local service could dry up. Local taxes paid might fall with the loss of jobs as well as the loss of taxes paid by the facility. These impacts could be felt by the wider community with them feeling the hit of financing the decommissioning project, changes to the infrastructure and public relations. With responsibility for the clean-up not having been clearly set out. With decommissioning imminent, stakeholders and the public may have a greater interest in the plant with concerns over spent fuel management, fuel storage and waste disposal strategies.

The effects that are felt will depend on the size of the workforce. A small workforce would probably not have that much of an effect of the economy, but a large workforce could have a dramatic effect.

Decommissioning could potentially increase jobs in the area for a short period of time. This could cause an increase in economic activity. Opportunities for local services may arise to provide support during the decommissioning phase. New facilities for spent fuel could create more jobs.

The socio-economic impact can be managed effectively. With careful planning and support the workforce, local community and wider community can be eased through the process. Financial support for workers, as they transition out of their roles as well as for the local community to support the demographic changes. Communication between stakeholders, the community and investors and management will make the process more successful. Legislation has been set out to support this process;

The Energy Act 2004 [33], which established the NDA, sees that organization

“as giving encouragement and other support to activities that benefit the social or economic life of communities living near designated installations, designated sites or designated facilities or that produce other environmental benefits for such communities.”

The NDA are not legally obliged to provide jobs for a redundant workforce but ethically they should take management of this programme. As with Dounreay (Annex VII for the case of Dounreay)

https://www-pub.iaea.org/MTCD/publications/PDF/trs464_web.pdf

Dounreay is a situated in a rural location with a very large number of staff completely reliant on the employment the power plant provides. The impact of loss is expected to extreme as the local community have become dependent on the Dounreay. Many people working at Dounreay are working in high-tech jobs and are being paid 30%-48% higher than the national average wage. This level of income will not be achievable outside of the nuclear industry in such a remote location. A site-wide environmental impact statement has been commissioned to create a baseline report.

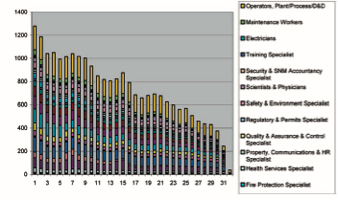

Below is a graph from the environmental impact statement showing how jobs have steadily fallen but also the swings in skill sets from year to year.

Figure 4 (Anon, 2018)

Eventually all jobs will come to an end but in the meantime, there must be greater planning when managing different skill sets. With skill sets being released once they were not needed anymore.

Unfortunately, there has been very poor planning for the future workforce of Dounreay with the local council concentrating more so on the local infrastructure. There has been resistance to suggest ideas for how the area will continue to grow economically after the closure of the site. Preferring to allow other bodies to suggest plans that they can then comment on. The highland and Islands Enterprise have been working to set up a strategy to prepare a vision of a regenerated local community in keeping with the closure of the Dounreay site. Many different views from the community and members of parliament have been taken into account so’s to create a sustainable plan that can provide a future business base for the community.

Members of the socioeconomic working group;

- J. Thurso MP (Chair)

- Lord McLennan of Rogart

- J. Stone MSP

- Caithness & Sutherland Enterprise North Highland College

- The Highland Council

- Highlands and Islands Enterprise

- The Nuclear Decommissioning Authority UKAEA

- Dounreay Stakeholder Group

- Local trades unions

- Local community councils

As previously said the NDA doesn’t have the responsibility to find workers new jobs but in the case of Dounreay, they are providing financial support to improve the economics of the local area and are eager to support new businesses. The area has a highly skilled work force that have been responsible for the construction and the running of the plant for the last 50 years.

Development in other areas include renewable energies due to the high winds and strong waves experienced in the area. Investors are being attracted into new developments. Many of the skills sets need for this type of development already exist in this area.

Political Issues

The UK government is now responsible for it decommissioning with the tax payer funding much of the costs, 85%.

Environmental Issues

Before decommissioning of a nuclear power plant can commence guidance must be given by the ONR ‘Guidance on the Nuclear Reactors (Environmental Impact Assessment for Decommissioning) Regulations 2018 (EIADR18).

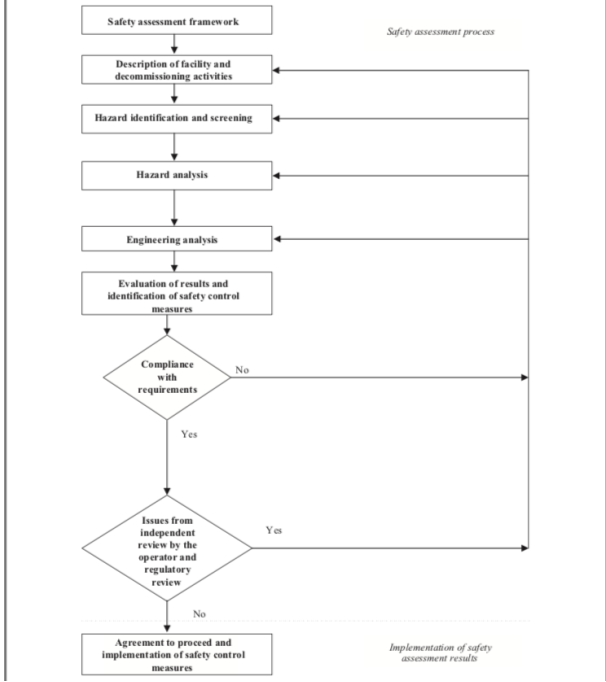

The ONR uses a process Flowchart to assess the environmental impact of decommissioning as shown below:

Figure 5 (Onr.org.uk, 2018)

Decommissioning and clean-up projects require consent granted by the ONR.

The are many environmental impacts that can happen as a result of the decommissioning of a nuclear power plant. A life Cycle Assessment will be conducted which will include the removal and demolition of the plant as well as the decontamination, conditioning, interim storage and final repository of low-level and interim-level waste disposal and recycling. Soil contamination can be an issue when decommissioning and power plant.

At the Dounreay site the effects of the site’s environmental impact are relatively low. Radioactive particles were released into the marine environment around the local area due to the reprocessing of nuclear fuels. Occasionally being washed up onto local beaches mainly the Dounreay Foreshore and Sandside Bay. But work has been undertaken to remove the highest activity particles from the offshore sediment and work is reviewed by the Particle Retrieval Advisory Group (Dounreay)(PRAG(D)). This work is expected to result in in a reduced number of particles remaining and in turn the amount that are being washed up. SEPA also run a programme to monitor beaches. Soil and ground water quality is also monitored as part of the Dounreay decommissioning and restoration programme. The site has closed its landfill and is monitoring groundwater in that area.

Safety Assessment

Before decommissioning can begin a Safety Assessment must be completed as part of a bigger decommissioning plan. The assessment will look at hazards, complexity and relative risks. The assessment will be carried out by experienced multidisciplinary team lead by a safety assessor.

Before the safety assessment can be under taken it is important to specify the frame work for the assessment. This includes specification, scope, objectives, timeframes, end states, requirements, outputs and safety approach.

Below shows an example of a Safety Assessment Process Flow Chart:

Figure 6 (Www-pub.iaea.org, 2018)

One of the first steps in developing a safety assessment is in identifying hazards, either existing or future. How the radiological/non-radiological effect the workers, members of the public and the environment. Below shows a List of Hazards and Risks Associated with Typical Decommissioning Activities.

|

Hazard |

Risk/pathway |

Control |

|

Decontamination, wet/dry |

||

|

Used radioactive decontamination solution and free radioactive liquids |

External radiation to workers; Routine atmospheric and liquid releases; |

Organization of work, use of shielding; |

|

Collected contaminated dust particles on dust extractor filters |

External radiation to workers; Internal contamination of workers |

Organization of work, use of shielding; |

|

Airborne aerosols released from liquids, foams, dust at work-place |

Internal exposure to workers from inhalation; Atmospheric routine release |

Use of protective masks; Stack monitoring with annual limits |

|

Decontamination solutions, foams |

Chemical toxicity to lungs and skin of workers |

Protection of breath (masks) and skin (protective gloves and clothing) |

|

Dismantling, cutting and manipulation with large pieces/equipment and parts |

||

|

Radioactive parts of dismantled equipment |

External radiation to workers |

Organization of work, use of shielding |

|

Dismantling of parts with traces of residual oils inside |

Fire |

Adequate drainage and availability of local fire extinguishers |

|

Airborne aerosols and gases released at work-place |

Internal exposure to workers from inhalation; Atmospheric routine release |

Respiratory protection, masks; Stack monitoring with annual limits |

|

Collected activated or contaminated dust particles on dust extractor filters |

External radiation to workers; Internal contamination of workers |

Organization of work, use of shielding; |

|

low contaminated materials, decontaminated and dismantled |

External radiation and internal contamination to workers; |

Organization of work, use of shielding; |

|

Organization of work, use of shielding; |

||

|

Physical injury to workers |

Fall from ladders or scaffolding; |

Use of certified equipment and adherence to occupational health regulations; |

|

Electric shock to workers |

Cutting or dismantling cabling that has not been disconnected |

Securing the disconnection of the electricity supply to the system to be dismantled |

|

Radioactive waste handling |

||

|

Treatment of liquid, dust and solid radioactive waste |

Exposure and contamination to workers and the environment via complex pathways |

Organization of work, use of shielding, masks and protective clothing; |

|

New solidified radioactive waste, transport and manipulation |

External radiation to workers |

Organization of work, use of shielding |

|

Decontamination, wet/dry |

||

|

Spill of decontamination fluid |

External and internal exposure to workers performing mitigating actions |

Organization of work, use of shielding and adequate clothing and masks for protection of workers from chemical hazards |

|

Fire, spread of steam and aerosols from radioactive materials, solutions and chemicals |

Accidental airborne radioactive and chemical release; |

Active ventilation; |

|

Failure of ventilation system |

Inhalation of radioactive substances to workers |

Monitoring of ventilation performance; |

|

Flood of radioactive solutions |

liquid release to surface water and underground water; |

Flood control measures; Test of groundwater contamination; Monitoring of radiation |

|

Fall of radioactive piece or equipment |

External radiation to workers |

Monitoring of radiation; Protective clothing; |

|

leak of liquid radioactive waste reservoir |

Release to underground water and the environment; External and internal exposure to workers |

(Periodic) integrity and material controls; Groundwater test for radioactive contamination; Use of shielding and adequate clothing and masks |

(https://www-pub.iaea.org/MTCD/publications/PDF/Pub1604_web.pdf)

At Dounreay Hazard Management Project has been funded £22 million. The money is intended to be used to build an extension to the waste store.

Reference & Bibliography

- Psa.ac.uk. (2018). [online] Available at: https://www.psa.ac.uk/sites/default/files/conference/papers/2015/KIM%20hyung%20Decommissioning_btw%20GB%20and%20KOR.pdf [Accessed 20 Dec. 2018].

- Www-pub.iaea.org. (2018). [online] Available at: https://www-pub.iaea.org/MTCD/publications/PDF/Pub1604_web.pdf [Accessed 20 Dec. 2018].

- Anon, (2018). [online] Available at: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/696420/Strategic_Environment_Assessment_site_specific_baseline.pdfde [Accessed 20 Dec. 2018].

- GOV.UK. (2018). Dounreay: management of exotic fuels and nuclear materials. [online] Available at: https://www.gov.uk/government/publications/dounreay-credible-options [Accessed 20 Dec. 2018].

- Sciencedirect.com. (2018). Bioaugmentation – an overview | ScienceDirect Topics. [online] Available at: https://www.sciencedirect.com/topics/earth-and-planetary-sciences/bioaugmentation [Accessed 20 Dec. 2018].

- Oecd-nea.org. (2018). [online] Available at: https://www.oecd-nea.org/rwm/reports/1999/decontec.pdf [Accessed 20 Dec. 2018].

- Sepa.org.uk. (2018). [online] Available at: https://www.sepa.org.uk/media/116693/dounreay-radioactive-waste-disposal-consultation-document.pdf [Accessed 20 Dec. 2018].

- Dounreaystakeholdergroup.org. (2018). [online] Available at: http://dounreaystakeholdergroup.org/files/downloads/download2758.pdf [Accessed 20 Dec. 2018].

- Sepa.org.uk. (2018). [online] Available at: https://www.sepa.org.uk/media/365893/2018-07-17-grr-publication-v1-0.pdf [Accessed 20 Dec. 2018].

- Anon, (2018). [online] Available at: http://www.dark-tourism.com/index.php/15-countries/individual-chapters/1152-dounreay-exhibition-thurso [Accessed 20 Dec. 2018].

- Onr.org.uk. (2018). ONR – Sites that we regulate: Dounreay. [online] Available at: http://www.onr.org.uk/sites/dounreay.htm [Accessed 20 Dec. 2018].

- Bayliss, C. and Langley, K. (2003). Nuclear Decommissioning, Waste Management, and Environmental Site Remediation. Burlington: Elsevier.

- Dounreay. (2002). Dounreay Site Restoration Plan: Looking Forward, Making Choices: UKAEA.

Table of Figures

Figure 1 Ambaile.org.uk. (2018). [online] Available at: http://www.ambaile.org.uk/preview/en/33591/1/EN33591Dounreay%20Experimental%20Reactor/Am%20Bail.jpg [Accessed 20 Dec. 2018].

Figure 2 Ukinventory.nda.gov.uk. (2018). [online] Available at: https://ukinventory.nda.gov.uk/wp-content/uploads/sites/18/2017/03/High-Level-Summary-UK-Radwaste-Inventory-2016.pdf [Accessed 20 Dec. 2018].

Figure 3 Anon, (2018). [online] Available at: https://www.researchgate.net/publication/317299150_Exploring_variability_among_quality_management_system_auditors_when_rating_the_severity_of_audit_findings_at_a_nuclear_power_plant [Accessed 20 Dec. 2018].

Figure 4 Onr.org.uk. (2018). [online] Available at: http://www.onr.org.uk/eiadrguidance.pdf [Accessed 20 Dec. 2018].

Figure 5Www-pub.iaea.org. (2018). [online] Available at: https://www-pub.iaea.org/MTCD/publications/PDF/Pub1604_web.pdf [Accessed 20 Dec. 2018].

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal