Development of Automatic Ice Cone Filling Machine

| ✅ Paper Type: Free Essay | ✅ Subject: Engineering |

| ✅ Wordcount: 2114 words | ✅ Published: 18 May 2020 |

Introduction–

My project is automatic ice cone filling machine this machine the scope of this study like designing or focuses the various terms and developing of ice cone filling machine which is available on different type of companies like small and medium or big industries. This filling machine having a power to done manually with lot of human sources or limiting the capability to fulfil the market groups demand whereas, to automate the whole process of filling ice cone machine this machine is controlled the output of the ice cone from the discharge the top of the nozzle of the robot my purpose to design the automatic ice cone filling machine it is save our time with the help of two software I make my project machine simulations is very important thing in industrial automated because with the of machine simulation we make project in different ways there are many things available in this software such as machine design or different type of factories size available and different type of components are available on my project automatic ice cone filling machine I can use large conveyor belt and four sensors and one robot and two sensors for robot and two for conveyor.

Background of our project-

i) Balemi is a famous proposed man they can interpretation of different type of survey control theory form the basic things output and input include. This system was constructed in the year of 1992 moreover, in this system are include many things like input output process and some command are accept that it is correct or not this process when command is accept output or input of project produced some various type of message related to some changes that were occurred in the system. Belemi found some different type of problem in this project like communication delay between PLC and machine simulation. (sew)

ii) Hellene it is also a famous man they an surveyor of this project Hellene can started surveyor in the year of 1996 in this project they suggested that the main reason this was of the relay between physical implementation and abstract supervisor this things are noticed when the implementation was to be totally based on PLCs moreover, in the year of 2006 they improved their came and structure with a flow.

Problem statement of my project – There are various problem I research in pervious project some problems like

i) Manual work

ii) low production

iii) efficiency

iv) time consuming

v) sensors problems

vi) low quality

But I have solve all this problems in my project In my project automatic ice cone filling machine i face different type of problems like-

1) During the project the some information are missing on internet.

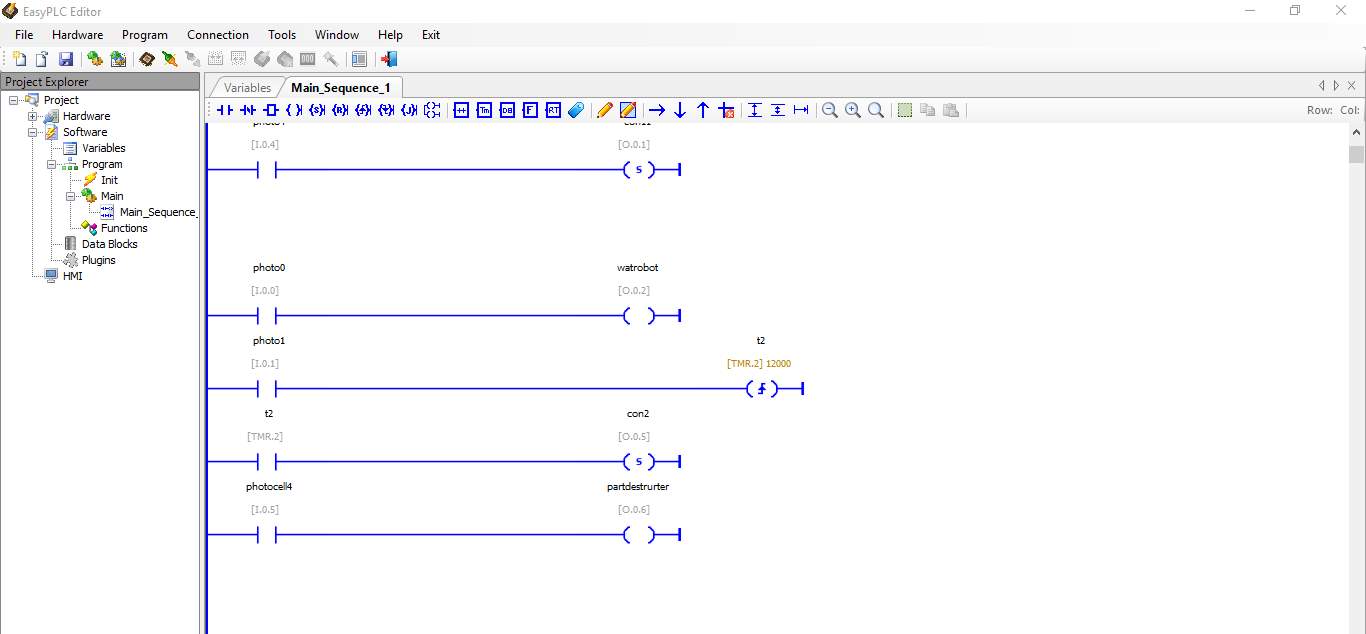

2) When I work on ladder programme I face problem about inputs and outputs.

3) When I work on Machine simulation I face problem on finding work parts.

4) I design a close loop system which can control conveyor by infrared sensor.

5) During the making project I put photocell sensor its very difficult to run.

6) I face problem in machine simulation after practice many time i learn simulation.

Project objectives-

1) Increase affiance while working on my project I put many thing in my project with the help of all thing I can make my project easy

2) This project is very important for big and small industry while I working on this project I put sensors to control the workparts.

3) I also put timer in my project with the help of ladder diagram its control the efficiency of work parts and work correct with the help of timer

4) It is also save a time and filling automatic ice cone in good way with the help of robot.

5) In this project I have to run the PLC ladder diagram and during this project this ladder diagram are very important in this subject .

Methodology-

This work is a finished utilization of robotization. The procedures constrained by PLC and observed by utilizing SCADA. PLC and SCADA are significant piece of the ice filling framework. As the framework controlled by the modified PLC and SCADA is utilized to observe the procedure in framework. This framework uses a begin/stop control of the motor when we on the switch at that point engine will be on. Cone are kept over a robot line . At the point when conveyor will switch on then transport will begin moving. At the moment that container go under the tank then a sensor sense the cone and the valve open for the specific time that set in the programming for that time the work parts in to the container. The described volume through which client can pick the volume of liquid to be filled. Machine simulation I can work on different thing and mainly have to operate the quality of my project with the help of machine simulation In my ladder program I make according to project I make ladder in proper way with the help of some inputs and outputs.In my project I have to add many things such as conveyor belt and robots and sensors and my workparts.PLC is in charge of the considerable number of tasks in our venture. The unfurled bundle is placed in the filling machine. a legitimate shape is given to the crate i.e a rectangular box.. The Selector switches are on and all out 1 bundles are sent at transport line simultaneously where the utmost switches are in charge of putting the ice cone are actually underneath the valve

Components use in our project-

|

s. no |

components |

type |

Quality |

|

1 |

sensors |

photocell |

4 |

|

2 |

robot |

Develop solder robot |

1 |

|

3 |

conveyor |

Simple roller |

2 |

The detail and description of each components is given below-

Sensor-

There are different type of sensor which are applied in the project all sensor I put in my project that was photocell sensors because this sensors are available in the software and also these sensor photocell are appropriate for my project automatic ice cone filling machine.

Photocells-

The functioning of my photocell 1 is given blow and the parameters and location of photocell

i) To run first conveyor belt

ii) 1 photocell for run robot

iii) 1 photocell for off robot

iv) To run second conveyor

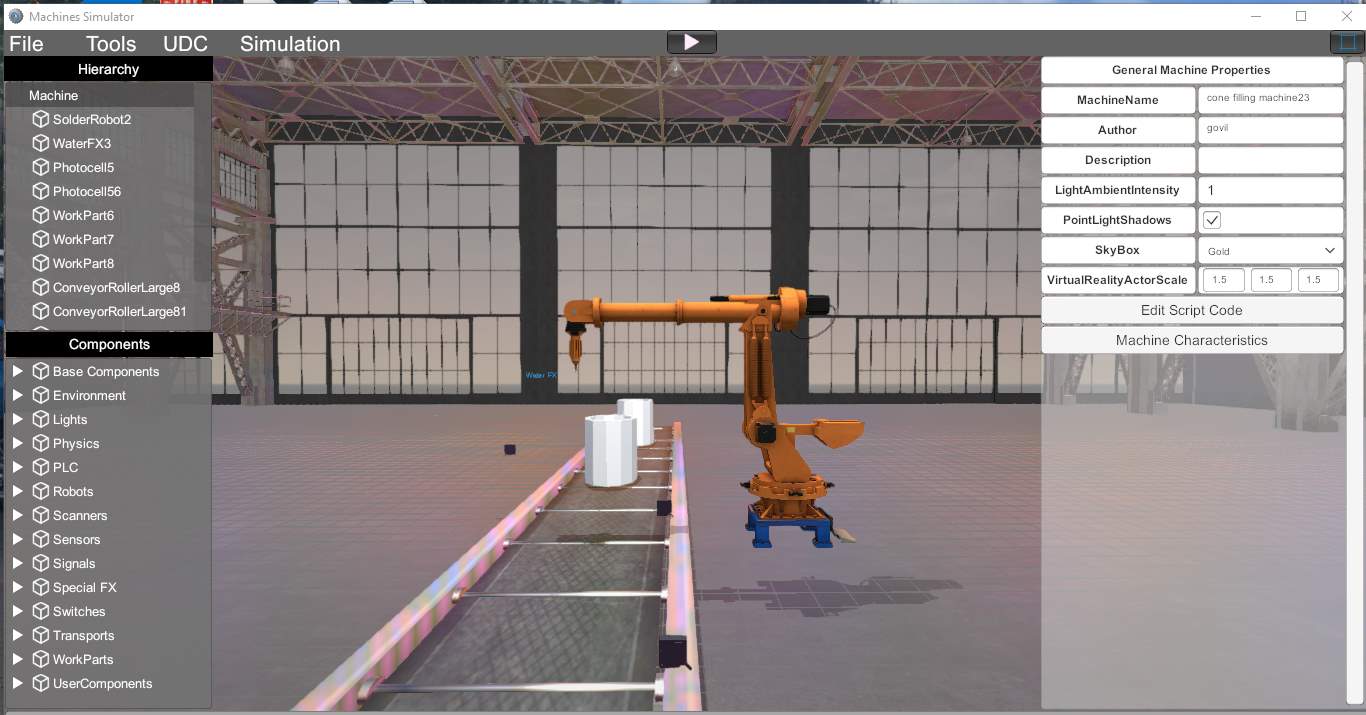

Figure 1 sensor

Robot-

i) Cone filling robot I have to develop this robot with the help of various thing in my project such as with the help of machine simulation software.

ii) This robot working to fill ice cone in the correct way

Conveyor belt-

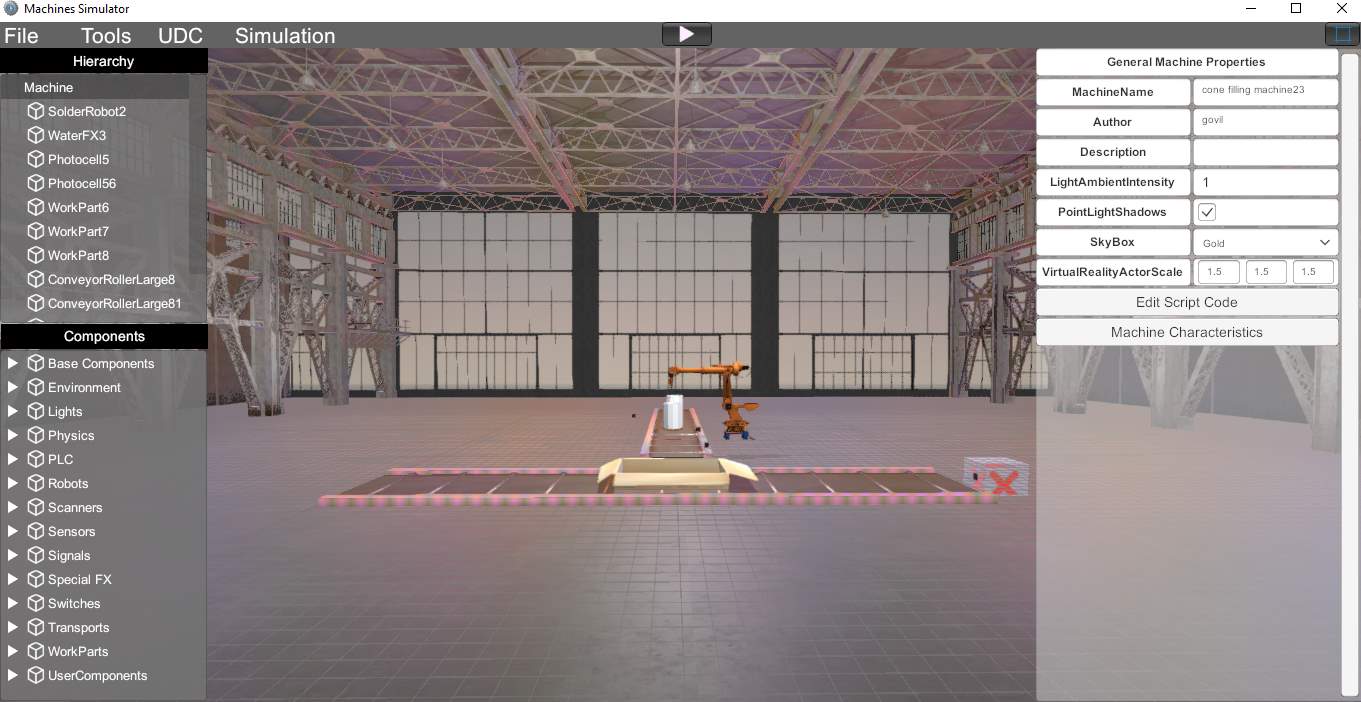

Figure 2 conveyor belt (Ananth1, 1995)

i) Establishments with transport lines can be planned essentially and reasonably by considering a couple of variables.

ii) I will talk about how clients can stay away from superfluous increases which climb up the cost and muddle generation.

iii) Two of the most well-known erroneous conclusions are an abundance of shafts and following aides.

iv) The specialist may have a sense of safety about the application, however the augmentations will

v) Make the establishment progressively delicate to abandons and less clean.

Project design-

Figure 3 project design

Working principle-

In my project ice cone filling machine I have include many things which was related to my project in this project I include conveyor belt I have two conveyor belt and one conveyor belt having one robot to fill all ice cone in correct way and conveyors having sensor as well to control everything in sequence and I put another two sensors in another conveyor belt At the information side the containers are kept in position over the conveyor moreover, after complete my simulation I worked on ladder diagram with the help of all correct variable my project is run I put some inputs and outputs according to my project whereas, The inductive nearness sensor is utilized to distinguish cone without reaching. These non-contact nearness sensor identify ferrous material, in a perfect world The yield is then perused by outside control unit (for example PLC) that changes over sensor ON and OFF state into useable data.

Result and discussion-

The programmable controller based ice cone filling machine the machine has very quicker execution timer and time and working successful moreover, coordination with lot of security measure to different type of investigation simplicity and materials of activity because of the hand to different hand to hand there are many components I have to show in my project but some equipment’s and progressively complex with good wiring and requires in my project automatic ice cone filling machine is consume time and limit of workers I have to make m project with the help of ladder programme in ladder programme I design according to m y work I put some inputs and outputs when I make all variable correct than my project run in ladder programme this project is very helpful in big companies.

1) It is very helpful project in ice cream company

2) Its is save the time

Ladder programme –

Figure 4 ladder program

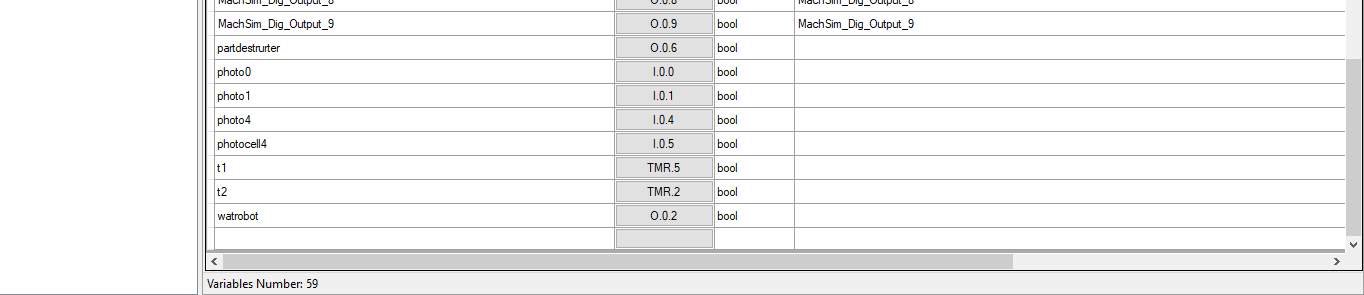

Variables –

Figure 5 variables

Figure 6 My variables

In the automatic ice cone filling machine it is also known as automatic robot which I use but I use different type of variables in my project and those variable are use in project are to run the system and different functions. The variable those I used in my project are given in figures. All different type of variables applied for the components like in the form of digital inputs and outputs.

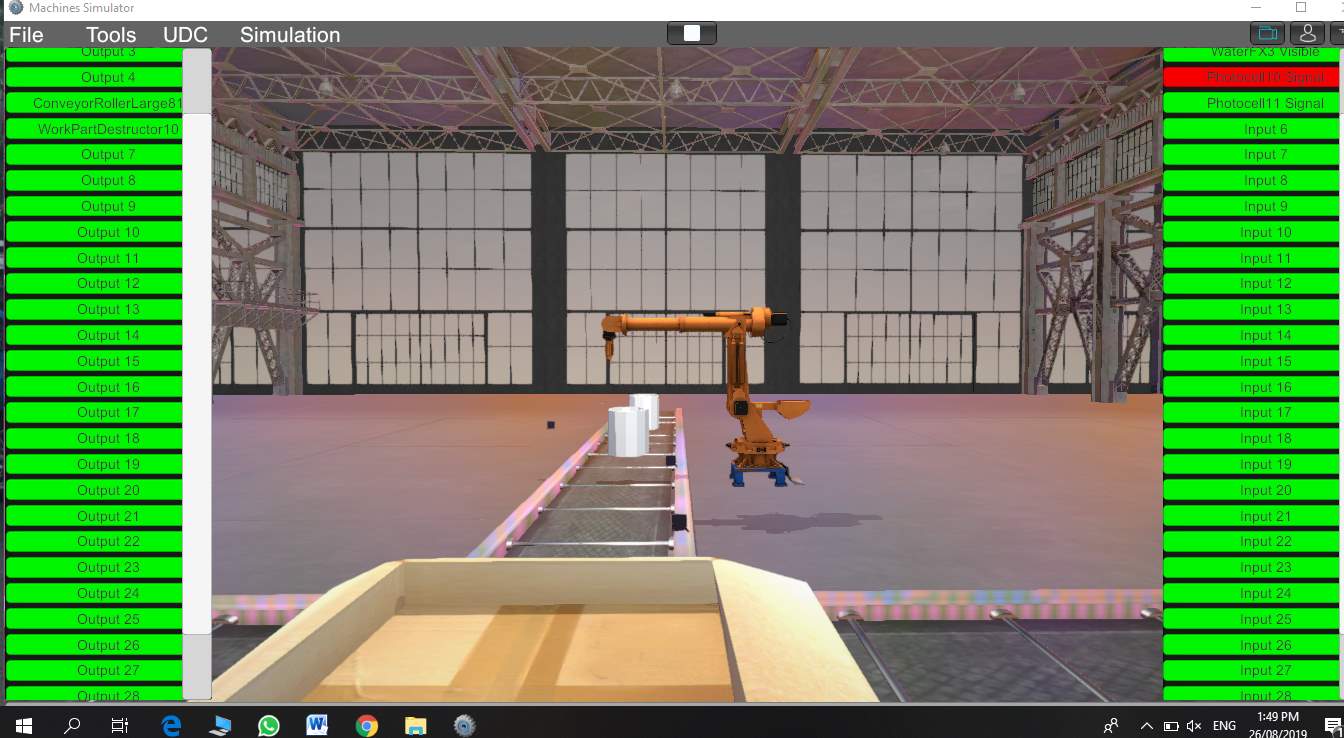

Project simulation-

Machine simulation finally I make my project in according to my work all things are correct I put some outputs and inputs according to my work as u see in figure I run my project properly with the of machine simulation software here you show I put one robot that was solder robot and two conveyor belt which I found in machine simulation software and I also include four sensors in my project and that can run with the help of ladder commands in ladder commands I make timer with the help timer sensors is run.

Bibliography

- Ananth1, K. N. (1995). DESIGN AND SELECTING THE PROPER CONVEYOR-BELT.

- sew, w. (n.d.). /processing filling. Retrieved from www.tetrapak.com: https://www.tetrapak.com/processing/filling/tetra-pak-ice-cream-filler-a3

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal