Study on Construction and Demolition Waste Recycling Centers

| ✅ Paper Type: Free Essay | ✅ Subject: Construction |

| ✅ Wordcount: 1442 words | ✅ Published: 03 Jul 2018 |

Introduction

The construction sector is an important solid waste generator. In Brazil, the recent economic and politics growth has rapidly encouraged further development and investment in the construction sector. Nevertheless, such speedy growth of the Brazilian’s construction has brought an elevated concern and attention to the waste problem and its management for a developing country growth like Brazil. Nagalli, 2012

Like in Europe, Brazil has a compulsory regulation on construction projects to reduce the construction and demolition waste. The national laws obligate the builders to be responsible for the waste of their works. It is legally consolidated and requires the builders a proactive posture in sense to planning the waste management. Nagalli, 2012. The municipalities are the responsible party on the waste management in Brazil, except for the private investments such as (industries, private constructions or demolitions, etc.). Báez et al. 2012.

However, only (11) which presents (0.25%) of about 5000 Brazilian municipalities have construction and demolition (C&D) waste recycling center As well as there are (13) stationary plants and recycling waste center produced in local communities. Therefore, it’s quite clear that a large part of the waste is not recycled in Brazil. It is also worth mentioning that since the established of CONAMA 2002 (Brazilian Environmental Protection Agency); things are moving better and all Brazilian local governments are nowadays obliged to prepare and adopt strategies for sustainable management of C&D waste. MMA, 2002. All investors are obliged to produce feasibility studies plans of the production and use of construction and demolition (C&D) wastes materials of each project. Notwithstanding, a very little amount of researches have been conducted to demonstrate the feasibility of the construction and demolition (C&D) waste recycling centers. Professional inquiries illustrated that private projects which produces 20 tons per hour (t/h) or less of C&D waste processing flow will probably not be met financially to continue, due to the low productivity and lack manufactured product prices, as the use of manufactured products are still not widespread so the investment in recycling on large scale with complex facilities centers will not be cost-effective neither.

02 – Feasibility Analysis :

Many studies and researches are taken place to develop plans for the feasibility study for the complex projects and the (C&D) waste recycling centers in Brazil. One of this study was by UNIDO (1987), which presented a structural model for feasibility studies to complex projects, including a huge investments from different sources of funding and simplify the study and structure then adding control elements described by another important study from Kohler (1997), the following main stages were identified in preliminary feasibility studies for construction and demolition (C&D) waste recycling centers as follows:

- Analysis of market needs and the amount of existing competition from different sources. Depends on the geographical location of the center.

- Assessment and estimated of waste generation. Depends on the geographical location of the center.

- The estimated incomes and cost from the construction and demolition waste.

- Investment analysis in construction and demolition waste field.

Market & Competition study analysis:

There are plentiful resources for civil construction combining several elements in Brazil. The main consumer construction and demolition waste centers are located in areas with good and convenient quality of different reserves.

According to DNPM (2003), “sand and gravel are low in price and produced in large quantities. Transport costs correspond to around 2/3 of the end price of the product, which make it necessary

to produce sand and gravel as near as possible to the consumer market, which are the urban agglomerates”.

In Brazil, which is one of the developing countries, the rate of consumption is estimated at approximately (2) tons /inhabitant a year. Sindipedras (2004). Comparing that figure with Europe countries, we found that Brazil has low consumption where the average consumption in Europe reaches (8-10) tons/inhabitant a year. Taking into account that the population in Brazil is about (180 million) IBGE(2000), so the total consumption estimated to nearly (270) tons a year about (175) million cubic meter.

Table no.1: The rate of construction aggregates prices without transport.( SINDIBRITA.2004).

Aggregates Aggregate grading

Prices (excl. taxes) ( Prices (incl.taxes)

|

(diameter in mm) |

(GBP $/m³) |

(GBP $/t) |

(GBP $/m³) |

(GBP $/t) |

|

|

Sands |

< 5.0 |

3.10 |

1.80 |

4.00 |

2.35 |

|

Stone powders |

< 5.0 |

3.10 |

2.00 |

4.00 |

2.55 |

|

Gravel 0, 1, 2, 3 |

from 5.0 to 75.0 |

3.80 |

2.60 |

4.85 |

3.36 |

|

Mixed Gravel |

from 5.0 to 55.0 |

3.10 |

1.75 |

4.00 |

2.27 |

ESTIMATED PRODUCTION OF C&D WASTE

We should know the productivity and collection of (C&D) waste to find out the needs and the interest of developing and establishing recycling centers. From Table no.2 below, estimates from the production and collection of construction and demolition (C&D) waste in some of the main Brazilian Cities:

Table 2: Estimative for production / collection of C&D waste in some Brazilian cities (Nunes, 2004)

|

Cities |

Estimative of C&D waste |

Year- |

Population (IBGE, |

Production per inhabitant (kg/inhab.day) |

Collection per inhabitant |

|

|

Produced |

Collected |

2000) |

(kg/inhab.day) |

|||

|

Riode Janeiro |

n/a |

1,100 |

2003 |

5,850,000 |

n/a |

0.20 |

|

Salvador |

n/a. |

2,750 |

2000 |

2,450,000 |

n/a |

1.15 |

|

São Paulo |

16,000 |

3,400 |

2001 |

10,440,000 |

1.55 |

0.40 |

|

Ribeirão Preto |

1,100 |

200 |

2003 |

505,000 |

2.00 |

0.55 |

|

São José |

740 |

n/a |

1995 |

540,000 |

1.50 |

n/a |

|

Piracicaba |

635 |

n/a. |

2003 |

330,000 |

1.88 |

n/a |

|

Vinhedo |

n/a. |

10 |

2003 |

48,000 |

n/a |

0.32 |

|

Guarulhos |

n/a. |

n/a. |

– |

1,100,000 |

n/a |

n/a |

|

Ribeirão Pires |

n/a. |

n/a. |

– |

105,000 |

n/a. |

n/a |

|

São José do Rio Preto |

690 |

n/a. |

1996 |

360,000 |

1.92 |

n/a |

|

Santo André |

1,000 |

n/a |

1996 |

650,000 |

1.56 |

n/a. |

|

Belo Horizonte |

n/a. |

2,300 |

2000 |

2,240,000 |

n/a |

1.05 |

|

Londrina |

1,300 |

n/a |

2003 |

450,000 |

2.86 |

n/a |

|

Brasília |

n/a. |

n/a |

– |

2,055,000 |

n/a |

n/a |

|

Macaé |

– |

40 |

2003 |

133,000 |

n/a |

0.34 |

|

Florianópolis |

635 |

n/a |

2001 |

286,000 |

2.23 |

n/a |

Averages 2.00 0.65

The Rio de Janeiro city estimates a collection of 1,100 ton/day (0.20 kg/inhabitant .day), an amount below the average in other cities under study. The reason that some municipalities are less than the average for the disposal of waste is the illegal and calculated within the general waste in official statistical tables. IBGE (2000)

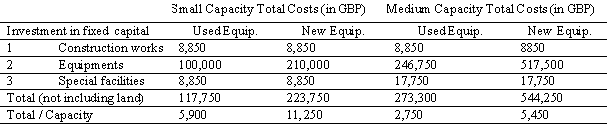

ESTIMATED REVENUES AND COSTS

In Brazil, the equipment used in the (C&D) waste recycling center requires large investment. Most equipment used in the mining sector, which is one of the largest and powerful sector in Brazil, this was calculated when analysis or estimate the profits and benefits of investment. The Table no.3 below shows the form of the fixed capital investment required for (20) tons/hour which we can call it as a small center and (100) tons/hour as a medium center depending on the size of the production and the new or used equipment. It’s possible to add some cost with equipment and site, the costs with site acquisition, transportation and the way of disposal the recycling center rejects. Nunes (2004)

Through consultations to many professionals, it was found that the minimum size of a site for a recycling center would be: (a) 6.000 m² the appropriate area for the (20) tons/hour recycling centers; (b) 30.000 m² area for the (100) tons/hour recycling centers.

Table 3: Investment in fixed capital and the operational costs (summary). SINDIBRITA (2004).

Operational Costs

Fixed Costs

|

1 |

Labour |

26,250 |

26,250 |

56,500 |

56,800 |

|

2 |

Other fixed costs |

65,450 |

76,000 |

280,250 |

307,400 |

|

Variable Costs |

|||||

|

3 |

Variable costs |

24,000 |

24,000 |

94,000 |

94,000 |

|

Total |

115,750 |

126,300 |

430,000 |

457,100 |

CONCLUSION:

The Brazilian civil construction’s aggregates are available in wide range with good quality and close to the urban consumer centers. It’s worth mentioning that both aggregates as well as several new construction projects prices have been low for some time. Hence, and in order to attract more clients and bring better attention to such industry, the prices of the recycled aggregates must be competitive with the natural aggregates. Meanwhile, the (C&D) waste reception as well as the recycling centers has to compete with the landfills. According to the Brazilian state-of-art, large amounts of inert material are usually needed to cover the landfill cells. The material is also required to build the access roads and maneuvering areas for the waste collection trucks on the landfills. Therefore, the inert landfills do set as high competitors with recycling centers in relation to reception of (C&D) waste. It was therefore recommended that two different recycling centers’ projects should be analyzed in order to capitalize and boost such industry forward: one, a small scale (20 t/h), and the other midsize (100 t/h) with the assumption of the use of processed products and the absence of (C&D) waste recycling projects in the country due to the lack of such industry tradition, the feasibility of future private recycling centers will initially be somewhere between the two aforementioned capacities. Nunes (2004)

References:

- André Nagalli , (2012) “Quantitative Method for Estimating Construction Waste Generation”

- Báez AG, Sáez PV, Merino MR, Navarro JG (2012). Waste Management.

- MMA (Ministry of the Environment) (2002) CONAMA Resolution no. 307.

- UNIDO (United Nations Industrial Development Organization) (1987).

- Kohler, G. (1997), Practice of Recycling: Construction Materials.

- CONAMA 2002(Brazilian Environmental Protection Agency).

- Ângulo, S. C. (2002) (Development of new markets for the recycling of C&D waste).

- DNPM (National Department for Mineral Research) (2006).

- Sindipedra (Federation of the Gravel Mining Industry of the State of São Paulo) (2004).

- IBGE (Brazilian Institute of Geography and Statistics) (2000)

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal