THE CHALLENGES IN THE MICROBIAL FUEL CELLS APPLICATION TO WASTEWATER TREATMENT

| ✓ Paper Type: Free Assignment | ✓ Study Level: University / Undergraduate |

| ✓ Wordcount: 2020 words | ✓ Published: 06 Jun 2019 |

Regardless of all the advantages and benefits this technology can offer to wastewater treatment, to energy production and to sludge reduction, there are certain barriers and hurdles this technique has to overcome in order to scaling up from laboratory level to real-world application. This limitations include low electricity production, electric current instability, high materials costs, among others. This section discusses the most important challenges of the application of Microbial Fuel Cells (MFCs), despite all the efforts that have been made to improve the performance and other factors.

- COD removal rates:

Clauwaert, Aelterman [1] discovered that carbon, nutrients and pollutants are removed in MFCs in a very low rate, indicating first a process management issues and second an additional need for design. On the other hand, Janicek, Fan [2] presented that a wide range of organic removal rates were reported in the literature with fluctuating values between 0.0053 and 5.57 gCOD/L/d with different material including manure slurry, domestic wastewater, synthetic wastewater, primary effluents, landfill leachate, among others. This results leaves a very high uncertainty factor in estimating the MFC performance when scaling up.

- Low power densities:

The energy output in MFCs is still too low to make an energy-neutral operation feasible at the practical scale [3]. This is one of the most important topics that researches should overcome in order to make this technology successful.

Regarding the literature, there is some inconsistency in power densities reported to date. A extensive range of power densities between 0.0018 and 2 W/

m2

(0.2 – 200 W/

m3

) were reported [2]. Despite this situation, power production capacities have grown up due to recent research efforts in this area, but still, it is not sufficient for scaling up this technology from laboratories to field applications. This recommends that more efforts should be dedicated to develop efficient power output configurations [4]. For better understanding of this limitation, researchers should focus in comprehend the role of biofilms and their metabolic functions in electron transfer may help develop robust and resilient MFC systems. [5].

- Integration with other beneficial processes

Due to the versatility of MFC operation (simple and straightforward), then it is possible to integrate this technique with other processes and operations to obtain a higher electricity production and higher sludge reduction. MFCs can be integrated with existing wastewater treatment system (active or passive) to enhance nutrient, energy and water resource recovery [6]. Likewise, MFCs could be used after the anaerobic digestion process or as a processing unit after the primary treatment or even as a standalone process to eliminate the organic compounds. Moreover, MFCs can be integrated into the existing wastewater treatment and management systems from domestic levels to a community level as well as systems in industrial sectors to grow their energy and resource utilization efficiencies [7]. Researchers have mentioned that in order to expand the application and overcome the MFCs limitations, it is necessary to integrate MFCs with conventional wastewater treatment process, which are classified as desalination MFCs (DS-MFCs), sediment MFCs (SMFCs), constructed wetland MFCs (CW-MFCs), membrane bioreactor MFCs (MBR-MFCs) and others. These combinations can not only improve the treatment, but also has the ability to be a self-sustained or even net energy producer [8, 9]

The Microbial desalination cell technology will be explained later in this paper.

- Costs associated with materials

One of the biggest challenges of the microbial fuel cells technology is the cost associated electrode and membrane materials. The capital cost of the MFC is 30 times higher (on average) than that of traditional activated sludge treatment systems for domestic wastewater, due to its arrangement and treatment [10]. Frequently, the high level capital cost in a MFC is principally caused by the use of expensive electrode materials, such as catalyst, current collector and separator materials [3]. According with different authors, the cost of electrode material is still a key factor limiting the practical application.

- Fouling at the membrane

Fouling at the membrane is one of the major factor limiting the MFCs’ application in wastewater treatment. It should be pointed out that membranes are expensive (as mentioned above). Particularly, biofouling leads to a decline in MFC performance because the interruption in proton migration and completion for substrate utilization [11, 12]. An alternatively to prevent this issue, membrane-less MFCs are now being widely investigated since their costs are less than the basic two-chamber MFC [13].

- Other challenges

The long-term stability of electrode materials is also a very crucial issue in wastewater treatment technology. This is a huge challenge for the researchers as well, because instability of the operation and process will lead unexpected results when scaling in a real-world scenario.

Other limitation of MFC and also a big challenge to break is that MFC cannot operate at low temperatures because microbial reactions are slow at low temperatures [14].

Other challenge to pass is that when utilizing microbial fuel cells, the power created by the cell might not be enough to run a sensor or a transmitter continuously. This can be treated by increasing the surface area of the electrodes or using a suitable power management program because the data are transferred when enough energy is stored (using a ultra-capacitor could be the solution) [15].

MICROBIAL DESALINATION CELL TECHNOLOGY

The microbial desalination cell (MDC) is a new technology which joints the microbial fuel cell (MFC) process and electrodialysis for water desalination, wastewater treatment and production of renewable energy. This technology could either be combined with other desalination processes, such as reverse osmosis or electrodialysis or can be used as a standalone process [16].

- Description of the process

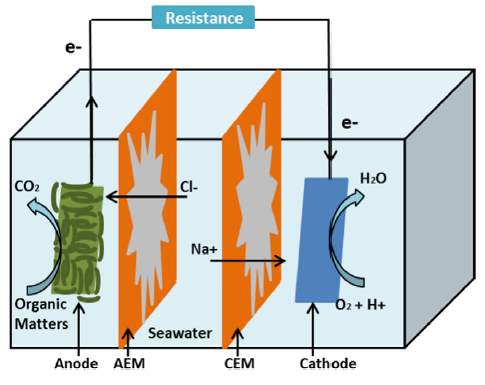

In a typical way, a MDC unit (Fig 1) consists of a desalination chamber in the middle built by inserting an anion exchange membrane (AEM) and a cation exchange membrane (CEM) on other side, plus an anode and cathode chambers. In this case, the middle chamber is responsible for salt removal, the anode chamber is responsible for electricity production and organic degradation, while the cathode chamber completes the electrical loop [16]

Fig 1. Typical scheme of microbial desalination cell [16]

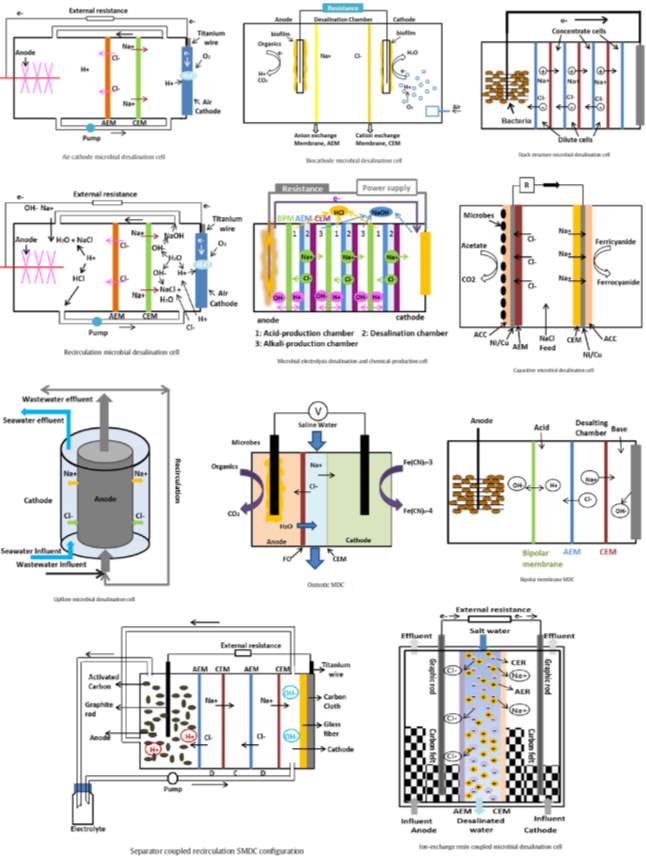

Below are presented the main Microbial desalination cell configurations (Fig 2).

- Air cathode MDC:

In this case, oxygen is used as a terminal electron acceptor and approximately 62% salt reduction. High reduction potential as a main advantage [16].

- Biocathode MDC:

For this case, catalyzes reduction reactions through use of microbes. This process is self-generating and sustainable, produces improved water desalination and decreases start-up time [16].

- Stack structured MDC:

Alternating AMEs and CEMs. Total desalination rate approximately 1.4 times that of a typical MDC unit. This process improves charge transfer efficiency, increases the separation of ion pairs from saltwater and increases energy recovery [16].

- Recirculation MDC:

Catholyte and anolyte solutions sequentially re-circulated through cell. Low concentration buffers should be used. This technique increases power density and also increases desalination efficiency [16].

- Microbial electrolysis desalination and chemical production cell:

This configuration is formed by introducing an acid production chamber and a bipolar membrane in an MEDC. This process reduces the pH fluctuations and increases the desalination rate [16].

- Capacitive MDC:

In this configuration there are three main key features: incorporates the concept of capacitive deionization, double layer capacitor is formed on the surface electrodes and salts should be frequently removed from electrodes. This process reduces salt contamination in anode and cathode chambers and resolves the ion migration problems [16].

- Upflow MDC:

In this process there is a tubular reactor containing two compartments divided by an ion exchange membrane (IEM). Main advantages are listed below: efficient fluid mixing inside the chambers, easy to scale up, enhances desalination efficiency and increases power density [16].

- Osmotic MDC:

Anion exchange membrane (AEM) replaced with forward osmosis membranes (FO). Increasing water flux results in dilute saltwater and for the technique Potassium ferricyanide is usually used as catalyst. Main advantages: enhances overall desalination performance, the cost of FO membranes is lower than the cost of AEM and improves organic matter removal from wastewater [16].

- Bipolar membrane MDC:

The bipolar membrane is placed next to the anode chamber, making 4 chambers in the microbial desalination cell. In this case, cation and anion selective layers are laminated together to make the bipolar membrane. This process allows high permselectivity, increases desalination efficiency, maintains desired pH in anode chamber and enables long life duration of the membranes [16].

- Decoupled MDC

In this technique, stainless steel mesh covered with carbon cloth is used as an electrode and also the anode and the cathode units are placed directly in salt solution. Main advantages: easy to scale up and to repair or replace any damaged part [16].

- Submerged microbial desalination-denitrification cell:

This technique integrates the denitrification system into a microbial desalination cell. In this case, the nitrate ions are removed from groundwater and also are used in electricity generation. There are 2 main benefits: there is no risk of bacteria leakage into groundwater and there is no additional treatment for nitrate required [16].

- Separator coupled stacked circulation MDC:

The key feature of this process is that a piece of glass fiber is attached to water facing one side of the cathode and acts as a separator. There are several benefits regarding this process: prevents biofouling on the cathode, increases the coulombic efficiency, decreases pH imbalance across the chambers of the microbial desalination cell and its operation is smooth for longer periods [16].

- Ion exchange resin coupled MDC:

In this technique, the desalination chamber is packed with mixed anion and cation exchange resins. There are 3 main advantages: reduces energy consumption, stabilizes ohmic resistance and improves the charge transfer efficiency and desalination rate [16].

CONCLUSIONS

- Even though the Microbial Fuel Cell offers more advantages and benefits among other technologies and process to wastewater treatment, sludge reduction and energy production, more efforts have to be made to achieve the transition from laboratory to real field application. The main challenges to scaling up are the low electricity production, high material costs and electric current instability.

- In order to expand the application and overcome the MFCs limitations, it is necessary to integrate MFCs with conventional wastewater treatment process. One important choice is the integration with the microbial desalination cells (MDC). This type of combination can obtain a higher electricity production and higher sludge reduction, while improving the treatment.

Fig 2. Microbial desalination cell configurations [16]

1. Clauwaert, P., et al., Minimizing losses in bio-electrochemical systems: the road to applications. Applied Microbiology and Biotechnology, 2008. 79(6): p. 901-913.

2. Janicek, A., Y. Fan, and H. Liu, Design of microbial fuel cells for practical application: a review and analysis of scale-up studies. Biofuels, 2014. 5(1): p. 79-92.

3. Do, M.H., et al., Challenges in the application of microbial fuel cells to wastewater treatment and energy production: A mini review. Science of The Total Environment, 2018. 639: p. 910-920.

4. Logan, B.E., et al., Assessment of Microbial Fuel Cell Configurations and Power Densities. Environmental Science & Technology Letters, 2015. 2(8): p. 206-214.

5. Gude, V.G., Energy and water autarky of wastewater treatment and power generation systems. Renewable and Sustainable Energy Reviews, 2015. 45: p. 52-68.

6. Xu, L., et al., The integrated processes for wastewater treatment based on the principle of microbial fuel cells: A review. Critical Reviews in Environmental Science and Technology, 2016. 46(1): p. 60-91.

7. Gude, V.G., Wastewater treatment in microbial fuel cells – an overview. Journal of Cleaner Production, 2016. 122: p. 287-307.

8. Fang, Z., et al., Electricity production from Azo dye wastewater using a microbial fuel cell coupled constructed wetland operating under different operating conditions. Biosensors and Bioelectronics, 2015. 68: p. 135-141.

9. Wang, Y.-K., et al., Development of a Novel Bioelectrochemical Membrane Reactor for Wastewater Treatment. Environmental Science & Technology, 2011. 45(21): p. 9256-9261.

10. He, L., et al., Advances in microbial fuel cells for wastewater treatment. Renewable and Sustainable Energy Reviews, 2017. 71: p. 388-403.

11. Choi, M.-J., et al., Effects of biofouling on ion transport through cation exchange membranes and microbial fuel cell performance. Bioresource Technology, 2011. 102(1): p. 298-303.

12. Xu, J., et al., Fouling of proton exchange membrane (PEM) deteriorates the performance of microbial fuel cell. Water Research, 2012. 46(6): p. 1817-1824.

13. Zhang, G., D.-J. Lee, and F. Cheng, Treatment of domestic sewage with anoxic/oxic membrane-less microbial fuel cell with intermittent aeration. Bioresource Technology, 2016. 218: p. 680-686.

14. Shantaram, A., et al., Wireless Sensors Powered by Microbial Fuel Cells. Environmental Science & Technology, 2005. 39(13): p. 5037-5042.

15. Rahimnejad, M., et al., A review on the effect of proton exchange membranes in microbial fuel cells. Biofuel Research Journal, 2014. 1(1): p. 7-15.

16. Saeed, H.M., et al., Microbial desalination cell technology: A review and a case study. Desalination, 2015. 359: p. 1-13.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this assignment and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal