Supply Chain Management of Kinik-Thai Company (KTC)

Info: 10041 words (40 pages) Dissertation

Published: 16th Dec 2019

Tagged: Supply Chain

Chapter 4: Results

Overview

This section summarizes the interviews’ data for the Kinik-Thai Company (KTC) and articles for Macphie of Glenbervie as the basis for next chapter’s discussions. Since this dissertation focuses on Thailand, the majority of the section is dedicated to the Thai KTC case while Macphie in UK case is addressed briefly and used as a basis for the comparative analysis about the similarities and differences between the implementation in developed and developing countries.

Company A: KINIK-THAI COMPANY LIMITED (KTC)

Kinik-Thai Company Limited (KTC) is a leading manufacturer and exporters of high quality grinding discs, vitrified bond wheels, and mounted wheels. The company is established in 1995 in the form of a joint venture between Thailand and Taiwan. Since Taiwan’s labor and overhead cost was significantly higher than Thailand, Kinik PLC, in Taiwan, has reallocated the factory and equipment to Thailand to operate under a profit sharing model and royalty fees (Sriratanaviriyakul et al., 2013). To expand its sales opportunity, KTC produces its own brand products as well as OEM products. The products are generally of high quality, durable, and second-to-none as they are approved by many international standard such as JIS, ISO 9001:2008, and EN 12413. The company consistently strives to improve the products’ performances and at the same time emphasizes safety to achieve highest consumer satisfaction. On average, the company produces over 50 million pieces of products, and profits an average annual sale of over 400 million Thai baht.

1. What is industry 4.0 at Thai KTC?

The participants have similar understanding of industry 4.0 concepts that it is a transformation of the production system by involving digital technology and the Internet. Specifically, the Managing Director defined industry 4.0 as “when the machines are able to produce variety of goods automatically and continuously without human intervention”. The IT Director added that CPS helps to store the products’ specification’ data while IoT facilitates the connectivity between the smart machine and products. The Manufacturing Director also stated that the current innovation such as 3D printing, Simulation, Virtual Reality, will be integrated into the new generation factory to improve efficiency. Some of the interviewees also mentioned of data- analytics use at the company. For instance, the Planning Director explained, “when the machine is working under Industry 4.0, the data will be generated as a byproduct; these data could then be decoded and analyzed to solve the managerial problems and optimize the business performances”. Thus, the business will make more logical decision as it will be relying on data, not on experiences and gut feeling.

2. Do you plan to implement industry 4.0 and why?

Based on the interviews, all participants showed interest and enthusiasm to implement Industry 4.0 into their SME’s supply chain as this will enhance their competitiveness and increase productivity. Concretely, the Procurement Director stated that, “the company is facing various cost pressures such as inflation of raw materials, labor wages and overhead cost, thus we will need to reduce those costs to improve the product margin”. He argued about the importance of Industry 4.0 technology and strongly voiced that if the company ignores this technology, it will not be able to compete effectively in the future. Therefore, the important question is not when to implement, but rather to what extent it should be implemented.

For an SME, to achieve the ideal supply chain, the Managing Director affirmed, “the company will require a large amount of upfront investment to program the whole supply chain systems as they need to buy many electronic components to allow the machines and systems to be interconnected”. The HR manager also added that managers will surely face employees’ resistance to change, especially from blue collar employees, who fear that implementing the new technology will result in job losses. The GM also mentioned that the government has introduced a revised tax policies for SMEs; “the SMEs that work with the innovation are exempted from the corporate income tax for 15 years”. This motivates the SME to implement new technology within their production system.

Yet, many interviewees also expressed their concerns on the government’s policies and other institutions. According to the company’s GM, although the government has to improve the IT infrastructure in the country and set up the standards to ensure that industry 4.0 in Thailand is implemented, he raised concerns about the ability of the government in these efforts especially because of the lack of infrastructure and manpower. Furthermore, he stated, “Nowadays, the banks do not approve the loan easily as they used to face with high NPL from being generous loaner”. At the same time, the HR director also stated that, “The Thai education is not suitable for industry 4.0 thus the ministry of education will need to work on improving the curriculum to fit with the ongoing business situation”.

Currently, the company identifies three investment phases in Industry 4.0. The first phase centralizes all data using ERP suites, the second phrase introduces a smart production systems while the third phase automates the warehousing and logistic systems. This identification is a result of the company’s inability to invest in the automation of the whole company due to financial limitations and cash flow shortage. It is noted that further improvements and implementation of Industry 4.0 will be subject with government’s and other institutions’ commitments to continuously support Thai SMEs.

3. How could it be used to streamline the supply chain?

The supply chain at KTC is a typical company’s manufacturing supply chain. The diagram, exhibited below, outlines the main processes as well as the supporting functions of the company.

Sales Process

The sales department establishes customers’ contact, develops relationships with the clients by providing information and assistance to customers throughout the transaction. The company does both house brand products and OEM products. The sales director aims to increase sales and turnover.

Regarding the current process (Figure 10), the sales Director stated “The sales managers currently introduces the company’s and its products to the potential customers during his/her visits and the sales executives are responsible for answering customers’ inquiries, provide customers support , and enter the data into the ERP system”. Since the product comes in various materials and sizes, the client is required to fill and submitted an order form in person or by email. Once received, the sales team enters the sales order into the ERP system, in which the program will automatically generate picking list to the procurement team, and cut down the raw material inventory. Then, packing slip is issued to the logistic team to notify them about the order delivery date while the invoice is sent to customers to remind them about the payment. The payment term depends on the negotiation however the tries to make special offers (i.e. 2/10 net 30) to motivate early payment.

For further improvements by implementing Industry 4.0, the sales director recommended, “The company can provide handheld devices, which is integrated with the ERP systems, to all the salesperson”. The device enables the salesperson to access the centrally allocated sales contents, training information databases in real time as a result of categorization and instant upload of the product catalogues into the server. For example, when the client wants to buy a metal cutting product, the salesperson could filter and introduce the product that fit the client’s requirements. Moreover, the salesperson could remotely check the inventory inside the warehouse and calculate the finished date for the OEM products based on the cycle time of each product. The device could be used to record or even modify the order even after the client agrees to execute the order. The ERP system will automatically create a picking list and packing slip to the procurement and logistic team respectively. At the same time, the system will also generate and printout the invoice for the customer at their site. Furthermore, it can also track the buying history, previous quotes and payment history. These initiatives will increase client responsiveness and consumer satisfaction while reducing the turnaround time.

Planning Process

The main duties of the planning team are to forecast each product and sum them up to achieve high demands. Based on the interview, the planning director clearly stated that “The department can only forecast the house-brand product while they cannot forecast quantity of OEM product because there is no association between the data”. For the company’s house-brand product, the analyst will look at past sales, trends and profit generating for each product in order to determine the order’s quantity to be produced and the amount of raw materials needed to cover the order. Since the company already started implementing the ERP systems, presenting this data in a single system will make it easy for the analyst to draw comparisons and make decision. As the OEM grows and becomes 60% of sale but still the company is unable to forecast demand and the planning director will use his/her ‘gut feeling’ to predict the order quantity. He exemplified “If the company needs 100 tons of grains, the director would recommend the company to order 300 tons of grains instead”.

To implement industry 4.0 into the system, the interviewee stated that “The process will remain the same; the house brand production will forecast based on the data available while the OEM will be produced as the orders are executed as it is deemed unpredictable”. Thus, manufacturing should operate at less than 100% capacity utilization to hedge against the demand uncertainty.

Procurement Process

The Procurement function generates relationship with the suppliers and procures the product at the best optimal cost. As a first step, the procurement manager searches for new suppliers to expand the supply chain. The procurement director meets and negotiates the conditions with the suppliers. During the interview process, the procurement director stated the following example;

“If the company needs to procure 5,000 boxes under the house brand design, 300 boxes under brand A and 500 boxes under brand B, and they will give 10% discount for the minimal order of 5,000 boxes with same design. The purchasing director will negotiate so that the cost per unit of boxes for Brand A and Brand B is equate to the cost per unit of house brand boxes [i.e. receive the discount for Brand A and B even though not reaching the minimal order]”.

At the same time, in the ERP system as in figure 11, the Procurement Executive will monitor the production schedule, the quantity of raw materials in the stock and how much more materials that are needed to cover the schedule; they will then make the purchase requisition accordingly. Later, the orders are distributed to different suppliers at a time to build good relationships, gain economy of scale advantage and avoid unforeseeable disruption. Afterwards, the ERP system will automatically generate Purchase orders to suppliers. Once the order is received, the procurement executive will generate packing slips to logistic department while receiving the purchase invoice. Lastly, the payment is settled as per the agreement.

To improve the procurement process using industry 4.0, the interviewee stated that, the procurement executive will need to order the raw material to cover the planned schedule. As the demand is very volatile, the company will also use reorder policy; when the material approaches the reorder level, it will automatically alert the buyer to make an order. In the future, the team suggested that reorder process to be automatic, hence the company will still use procurement to make the order. At the same time, the company will need to negotiate with new suppliers and ensure that the two systems could be integrated.

Additionally, the company should also categorize raw materials into two groups; strategic goods and non-strategic goods. Strategic goods refer to the raw materials that can differentiate the final product from the competitors’ and vice versa. The procurement director stated that, “Procurement will focus on building relationships with strategic suppliers to ensure competitive edge whilst the non-strategic product order will be automatically executed as soon as it reaches the reorder point”. The suppliers will be selected based on various dimensions such as cost, quality, time and compatibility. These strategies allow the procurement staff to prioritize the importance of each supplier and focus mainly on high priority suppliers as this would best contribute to the company’ competitiveness.

The Manufacturing Process

Currently, the factory uses a combination of labor and automated machine to manufacture products as in Figure 12. After the planning team enters all the orders into the system, the ERP will automatically prepare master production schedule, which details the orders, production time, lead time, batch sizes, machine to be used and working hours. The employee can then start the production process. The Manufacturing Director explained the process of making resinoid bond as follows; the process starts with mixing the abrasive grains, bonding materials and additive according to a specific formula. The ingredients are then poured into the mold and the binder, which help the product to retain the shape while solidifying, are inserted. Then, it is compressed by using a hydraulic pressing machine to form a shape. After that, the wheel is fired in the oven so that the binder converts itself into heat and solvents resistance substances which hold the abrasive grains together. After manufacturing, the product will be. Lastly, the products are transferred to the QC department; the products are checked for certain qualities including thickness and the size of arbor hole. The company produces 10% more than what is needed in case that there are defects or the client needs more of the product(s) immediately. In term of capacity management, the utilization rate is at 60% so that there is leftover capacity which can be used to produce OEM product or highly demand house-brand products. At the end of each day, the quantity produced in each process will be manually tabulated into the ERP system.

As to implement industry 4.0, the process should be automated as much as possible to improve the overall functionality. Specifically, the manufacturing director recommended,

“The machine should pull the master schedule data from the planning department into the machine. As machine attains the data from the system, it will automatically inject the raw material into a mixing bowl in accordance to the data. The automated machine will mix the raw materials, inject them in the mold, and compress it to form a shape. After that, the products will be transferred, by the conveyor belt, to the oven. Lastly, they will be moved into packaging station and storage area.”

He also added that the manufacturing departments can work 24 hours during peak demand period to supply the products in timely manner resulting in increase in profitability. As the workers will monitor the process, it will not be too tiring for them.

These strategies will allow the production to be flexible and responsive. As the overall production processes will be handled automatically, there will be fewer quality problems resulting in less materials’ waste, personnel and operation costs. Lastly, censors would generate large amount of data; this could be used to analyze and make an informed decision to leap further performances.

Distribution Process

The logistic department is responsible for warehousing and dispatching the products to the clients at the right quality, place and time. Once the products have been manufactured, the process will depend on whether it is a house brand or an OEM product;

House-brand

The House-Brand products are transferred to the warehouse in Bangkok. Upon arrival, the staff checks the stock and shelf the product using a forklift. Once there an order is placed by the retail shop or the clients, the ERP automatically reduce the stock on hand and alert the team about the dispatching date. According to the logistic director, “The system provides accurate detail about what is sold during the day to allow the manufacturing team to modify production quantity and schedule”. The products are then moved to the dispatching area, loaded, checked and delivered to the recipients. Small stocks are delivered by pick up while large stocks are delivered by trucks.

OEM Products

The OEM products dispatching policy varies upon the situation. For clients with a large order, the OEM products are loaded and delivered directly from factory to the clients’ site. For a small order, the orders are separated by their location. If the consolidate orders for the area are large, they are delivered by truck, but if not, then they will be deliver by a small pickup.

To implement industry 4.0 in the process, there are several ways for the automation of the warehouse and the logistics system. The AIs could fully or partially manage the tasks from receiving goods until the delivery of the goods to the recipients. However, the interviewee exerted that, “It will only happen in long term because it will require huge investment as the company will need to purchase the expensive software from international vendors”. Moreover, he continued, “Since the company already plans to automate the manufacturing process, it would not be sensible to invest in both functions due to limited budget”. He further elaborated that, Thai companies are not ready for cars automation as the IT infrastructure is not yet fully developed. Instead, GPS systems will be implemented to provide an optimal path for drivers to the delivery destination and to track each vehicle’s location.

Supporting Team

The supporting departments, including Management, HR, Accounting/Finance, IT and Maintenance departments, help the processing team to solve many issues. Currently, the IT Director admitted that, “We are running after the problem as we can only solve the problem after it happens; some takes very long to fix while many are quick and easy”. The General Manager added that, as the company runs the machine at 60% utilization rate, there are idle capacity in many machines hence the staff could simply shift to another machine instead”.

To improve the system, the General Manager said, “The Company will build a virtual factory system, from the ERP data, to oversee the process within the company and to response to problems instantaneously to avoid the disruptions”. The data will be shown in graphical form such as gauge indicator, graphs or color status so that it is easier for management to identify the problems. Moreover, the dashboard can be watched from any portable devices to allow the progress to be monitored by top management remotely.

Moreover, based on the interview with the Managing Director, “It is essential for the company to identify unique proposition or business model for the products or service, and be responsive to the market needs”. For instance, the company could position itself as a construction material consultant instead of just construction material merchandisers. In its place of pricing which is based on the quantity purchase, it can offer a service package in which the clients will need to pay large sum of money while receiving the advises and products from the expert from the start until the end of the project.

After implementing the process, the KTC supply chain will become more responsive to the drastic demand changes, as exhibited in figure 13.

4. What are the challenges of initiating industry 4.0 within the company?

Issue 1: Change in organizational structure

As industry 4.0 becomes prominent, organizational structure as well as functionalities will be affected substantially. There will be considerably high demand for IT personnel whilst the blue-collar job will be reduced significantly.

Industry 4.0 will require new skills and talents such as data analysis, business intelligence, designers and programmers. In fact, the majority of SMEs in Thailand including the research’s company has underinvested and has little awareness of understanding the IT management for business. Manager without IT knowledge will find it difficult to survive in today’s economy where organizations are in the process of introducing Industry 4.0 technology. According to the HR Director, “Millennial workers could be a great solution however they are more willing to work in multinational company rather than SMEs because they believe that they not only will gain higher credibility, but they will be paid higher than the rate in medium size firms”. Moreover, the factory is also located far away from the urban area, which in turn makes recruiting highly qualified IT personnel a challenge. To solve this problem, the HR team would design attractive and competitive salary packages (i.e. meritocracy bonus or higher than average salary), oversea scholarship and employment package (i.e. 1.5 months paid leave) and a good transportation facilities for staff in order to encourage young IT professionals to apply for positions at the company.

On another hand, industry 4.0 will take over many functions such as machine controller. Although many jobs will be replaced by intelligence machines, human will still be essential in the production system because AI is superior at the routine tasks, but they are unable to solve the problems that has not been programmed. The IT Director explained “When the materials are delayed, human will need to close the order and continue with the next one”. Therefore, it is deduced that, the staff will move from acting roles to supervision roles instead. Blue collars will work on tactical level tasks such as maintenance to keep the operations uninterrupted and perform final check on the product based on the specifications while white collar will focus on strategic level tasks such as how to improve the system efficiency and product to create incomparable competitive edge. To make this happen, HR Director posited, “We will need to create training sessions which allow the staff to become familiar with the new operations and keep up with technological progress”.

While some employees will be moved to more value-added job, many will also be asked to resign or simply lose their positions. Therefore, HR Director said that, “We will need to think of the remuneration policy that will strike the balance between the company’s and employees’ benefit”. As in many other companies, the policy will be based on a voluntary basis to lower the pressure from the employees.

Issue 2: Compatibility between the operation systems

Since companies utilize different operating systems, implementing industry 4.0 will only connect all the processes within the company rather than connect the whole supply chain. The Procurement Director gave the following example, “In procurement function, the ERP could only alert the buyers when the raw material reaches the reorder point, but it is unable to execute the order as the operation system are not compatible with each other”. Therefore, the company should make compatibility a main criterion along with existing criteria such as Time, Cost and Scope.

Issue 3: Investment

Implementing industry 4.0 requires a large upfront investment to transform the whole system. As the company has already implemented an ERP system, which consolidates all the data into one database to facilitate the information flows, the current focus is to automate the production systems. The IT Director stated that, “Since Thailand cannot create automated machine by itself, the company will need to purchase from developed countries, and it is expected to be sold at a very high cost”. Moreover, he continued that, the company will need to procure censors, machines and other components to allow the machines to be interconnected. There will also be additional charge on hiring consulting firms to assist in implementing the projects. The GM added, “After the first phrase of implementation, it can result in high debt equity ratio which can result in the company unable to loan more investment resulting in unable to scale up the system” To solve the problem, the top management could increase the equity to decrease the debt ratio and increase the debt allowance.

Issue 4: Accounting

The Accounting department is responsible for all the company’s financial issues and follow standards in preparing financial statements. In addition, it prepares other statements which help to improve the company’s performance. The GM explained,

“As the company has implement ERP system last year, the company will set up direct labor hourly rate and overhead hourly burning rate into the ERP program. It will then calculate all the indirect cost based on the operating time, and will accumulate them into direct cost to form the final production cost”.

With industry 4.0, the accountants can obtain the previously unobtainable data in real-time. Specifically, the direct cost and indirect cost can be obtained based on the introduced CPS sensor, which will allow the company to make a sound decision regarding costing and pricing decision. Although it does not help in facilitating the flow, but it can help to improve the resources efficiency as well as company’s profitability. As this becomes prominent, the GAAP may change the account reporting standard hence the accountants will need to follow up on the issues and become more familiar with technological & IT knowledge.

Issue 5: Disruption

In Thailand, there are many flooding incidents especially in the rainy season (May to September). As a consequence of the large flood in 2011, many FDI factories started moving their production to other developing nations (Fernquest, 2011). While it is a good idea, SMEs could not just simply do that due to their resource scarcity. To mitigate the risk, the company could elevate the shop floor and build a brick wall surrounded the factory to avoid the flood leaking into the factory.

The Production Director exerted that, “Machine may have a major breakdown during the production disrupting the whole supply chain system”. To mitigate the problem, they would need to outsource the order to other suppliers.

Cyber Security may also cause the disruption of the smart factory system. The IT Director admitted, “There are many security threats that can ruin the supply chain however we are not capable of developing the antivirus software, therefore we will purchase the security suites from the vendors”. He further added, many cyber security problems arise as a result of employees’ faults wrongly opening fishing emails, therefore the company needs to raise employees’ awareness, develop proper training sessions and disseminate security policies to make them available to employees. In addition, the company might employ specialists in cyber security so any security issues would be dealt with instantaneously. Finally, the company’s data should have a backup server to protect company’s vital data in unanticipated situations.

Issue 6: Education

Thailand suffers from a non-standardized educational system. The HR Director stated that, “There is a large gap between the curriculum of institutions; the students from Top Universities in Thailand are knowledgeable in their field of expert, but I cannot see that from students at Technical Universities”. She added that many Universities do not update their textbooks so the students in 2016 used old textbook published way back in 2002. Lastly, the MD added that it is essential to develop IT literacy, which will be highly demand when Industry 4.0 become more prominent.

Issue 7: Government

Although government plans to implement Thailand 4.0, citizens still have doubt with its policies, rules and regulations. The IT Director voiced his opinion stating that, “The Thai government is very corrupted therefore we face the problem such as lower specification of infrastructure”. He also gave a clear example of Airport Link Train in Thailand last year; the train broke down twice in two months. This is a result of maintenance not being standardized. If this scenario happens when Industry 4.0 is implemented, many companies will be disrupted. Lastly, due to political instability, there are risks of discontinuing the effort of the previous government.

Company B: Macphie of Glenbervie, UK

Macphie of Glenbervie, started in 1928, is one of the UK’s leading food ingredients manufacturer (SMAS, 2016). It produces various culinary products such as sauces, bakery mixes and desserts for retailers and manufacturer globally including Mark & Spencer and Ben & Jerry. The company is renowned for using various innovative techniques to improve its supply chain, resulting in increasing operating profit by 7%, which accounts for almost 48 million pound (Findlay, 2017). Despite being a leader, the company continuously strives to improve its business and manufacturing processes. This is evident by the introduction of the following initiatives;

- The company is highly motivated to implement industry 4.0 into the process because the Operation Director believed that, “Innovation is the key to unlocking opportunities for the growth in the food and drink sector” and he is confident that the company should invest in technology as it will improve the supply chain processes and productivity (Findlay, 2017). In fact, the company also allocates 1-million-pound investment for new innovative machines.

- As the company does not have much know-how on technology, it partnered with Scottish Manufacturing Advisory Service (SMAS) to gain advises on industry 4.0 implementation. Since Macphie has been utilizing ERP system to control and visualize the supply chain for a long period, industry 4.0 becomes easier to implemented.

- Since the company produces many product, the author will focus on the chocolate sauce product, which is done autonomously (Figure 14). First, the company receive the cocoa bean that is being harvested, fermented and dried (Owen, 2013). RFID tag is attached to the cocoa bins to allow identification and traceability. The staff then pour the cocoa bean in a hot air stream machine to improve the flavor and ensure that it is roasted evenly. The censor is used to make sure that the temperature are stabilized throughout the task (SMAS, 2016). After that, the roasted beans are transferred to the mill where the bean are cracked and the shell are vacuumed by the fan. The beans are automatically poured and grounded in stone rollers until they become cocoa liquor or paste. As there are lot of cocoa butter in the liquor, it is being removed using giant press machine. During the process, sugar and milk powder are added into the chocolate to make it tasty. The machine autonomously continue to mix and grind until the ingredients are fully mixed. Throughout the grounding process, the temperature are being monitored and it is being time in accordance to the standard (SMAS, 2016). Then, the chocolate liquor is transferred into evaporator and rollers to squeeze out the solid grain. After cooling down process, the chocolate content is being checked for fat, moisture and sugar (ibid.). Lastly, the machine injected the chocolate content into the labelled bottle. Production overhead is also being monitor throughout the whole process to reduce the manufacturing cost (Findlay, 2017).

- The company becomes the first food manufacturer to adopt renewable technology for its production at Aberdeen headquarters. Specifically, the company installed biomass boilers, which is operated on the locally sourced woodchips, and two wind turbines. These multimillion investments resulted in the reduction of carbon by 2100 tons a year (SMAS, 2016).

- Since the company installed many automated machines and robots at Glenbervie plant, manual handling risks are significantly reduced (SMAS, 2016). For example, in the past, the workers had to stack boxes of ingredients, such as butter, in sub-zero temperature storage. However, the management has now replaced this with the “Artic Robot” to build pallets of boxes. The sensor technology keeps the process fast, efficient and safe (Findlay, 2017). This resulted in minimal exposure to severe temperature for the workforces. By implementing automated machines and robots into the operations’ system, the company could also provide value-added job for the workforce (SMAS, 2016).

Despite many advantages from implementing industry 4.0, the company also exercises few problems;

- As the company implements industry 4.0, large amount of data has been generated. And, its IT infrastructure often becomes malfunction as the capacity is occupied (Castle C-S, n.d.). Thus, the company upgrades its IT infrastructure as well as enhance the back-up arrangement in case of disruption.

- Since the company believed that, “Investment in new equipment and technologies will only generate a return if there is a skilled workforce capable of getting the most out of the new manufacturing technology” (SMAS, 2016, pp.20). Specifically, employees are moved from blue-collar job to the more value added task, they might not be familiar with new task. Therefore, the training is being provided to improve employees’ skills and ensure that they are familiar with the new tasks.

- In the future, the company will have to hire experienced employees in digital manufacturing with knowledge on circular economy (SMAS, 2016). At the same time, the government is encouraged to provide more fund in improving the Science, Technology, Engineering and Math (STEM) to improve professionalism of the future workforce.

Additionally, to progress even further, it is not only about the company, but it is also about other stakeholders as well;

- After leaving the EU, the British government is committed to more involvement in supporting businesses and to develop policies for the post EU era. Similar to the German, US and Chinese economies which encouraged public investment in R&D, the UK followed suit by investing more in R&D resulting in a £4.7bn increase over the past 4 years, the biggest increase in R&D budget since 1979 (Termperton, 2017). Extra funding will also be invested to create jobs and support businesses in struggling economic areas. In addition, the Scottish Government has invested 1.5 million pounds over two years to enable Scottish Funding Council to develop young workforces as well as tackle inequality in apprenticeships (SMAS, 2016). In the long run, the government also plans to upgrade the infrastructure and improve vocational education to be in-line with job demand.

- At the same time, there are external associations, such as the Scottish Funding Council, Skill Development Scotland, Scottish Manufacturing Advisory and Service, which actively create frameworks to improve the productivity and actions plan for all the stakeholders including the organizations, governments and other institutions. This can accelerate the growth of Industry 4.0 implementation in UK as it is supported directly from the industry.

- As Universities in Scotland are highly ranked in the world ranking; it is proved that Education in Scotland is highly respected by the Academia globally (SMAS, 2016). Hence, the University will need to improve its curriculum to fit the future business environments and job demand.

Chapter 5: Discussion

Overview

This chapter discusses implication of the findings based on literature reviews and interviews to strategically answer the 3 objectives:

- Objective 1: To understand the definition of industry 4.0

- Objective 2: To apprehend the usages and challenges of industry 4.0 on SMEs in Thailand?

- Objective 3: To identify the similarities and differences of implementing industry 4.0 in developed and developing countries

Objective 1: Understand the definition of industry 4.0

Industry 4.0, also known as Smart Factory, Factory of Future, is still a very contemporary topic for researchers (Lu, 2017). Various authors provided diverse definitions for Industry 4.0 because of its broad topic. Schafer and Huxtable (2016) then defined the 8 building blocks to fully scope the definition of the topic. It is comprised of 1) Internet of Things, 2) Internet of Service, 3) Cyber Physical System, 4) Smart Factory, 5) Big Data 6) Cloud Computing 7) Cyber Security 8) Autonomy. Based on the literature and interview, the author reach the following concluding remarks:

- Internet of Things (IoT) works as a facilitator which connects smart machines and smart products. Supported by IoT, businesses are expected to witness increase in innovation which will eventually transform the current production systems as well as the world we live in.

- Internet of Services (IoS) is when one company grant contemporary access to another party (SAP, 2012). The company may need to introduce new business idea, to become more profitability. For example, Rolls-Royce does not sell the engine, but it rent out the engine and charge the service fee instead.

- Cyber Physical System (CPS) is a technology that allows the product to store its specification. In the future, practitioners will be looking for ways to improve CPS reliability and capability while ensuring harmonization with human (Li, 2017).

- Smart factory is when the supply chains are capable of sourcing the raw material, producing variety of products and delivering the products to the recipient with low level of human intervention. As machines are more rationale than human, this transformation would eventually improve the efficiency and error reduction and waste (Schrauf & Berttram, 2016).

- Big data is when the system creates a virtual copy of physical world through sensor data (Marr, 2016). When machines are working under FoF, the data will be generated as a byproduct. This data and its analysis could then be used to solve the managerial problems and optimize business performances. The business will solely rely on data not gut feeling.

- Cloud computing is a network to store documents, orders, models, simulation models and order requirement etc. As production data is stored in the cloud, it can customize orders through the internet without interrupting the production schedule (Ruggaber, 2006).

- Industry 4.0 is will be vulnerable to security attacks. Currently, AI is capable of generating the necessary malware that can avert the anti-virus program. Thus, the company should consistently update the security policies as insufficient security could cause a serious of disruption to the whole supply chain (Yan et al., 2012). Yet, for SMEs it is rather difficult to do that as the lack the necessary security infrastructure due to financial limitations as well as the expertise.

- Autonomy refers to machine learning or when the robot is able to learn by itself by using reasoning. Currently, there is a controversial issue whether machine learning will pose the opportunity or threat towards humanity (Field, 2017). In Thailand, many companies will still use basic function machines as the advance machines could be too expensive.

Prior to the implementation of the Industry 4.0, the management team should develop an understanding its full impact on the organization as well as full understanding of what it can or cannot achieve in order to ensure maximum benefits from it. As per the interviews, it is evidenced that different departments have different knowledge on the building blocks of Industry 4.0. Hence, the transition to Industry 4.0 might be easier to achieve.

Objective 2: To apprehend the usages and challenges of implementing industry 4.0 on SMEs in Thailand?

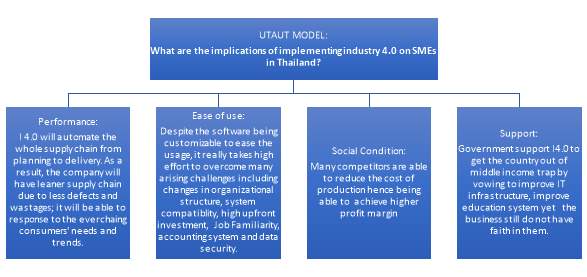

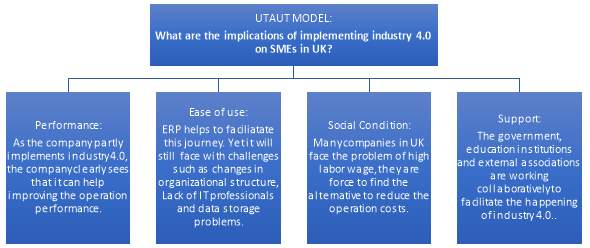

To successfully implement Industry 4.0, the technology should be accepted by all the stakeholders within the company (Davis et.al, 1989). One of the most prominent models is the Unified Theory of Acceptance and Use of Technology (UTAUT). The theory indicates that there are four key variables 1) Performance Expectancy, 2) Effort Expectancy, 3) Social Influence, and 4) Facilitating Conditions (Venkatesh et al, 2003). The author then compares an SME company in Thailand (Figure 14) to an SME in the UK (Figure 15) to draw the similarities and differences regarding the technology’s acceptance in both.

Company A: KINIK-THAI COMPANY (KTC), THAILAND

- Performance Expectancy refers to the extent that the stakeholders believe that the innovation will increase productivity and enhance performance (Venkatesh et al, 2003). Based on the literature and the interview, it can be deduced that industry 4.0 could be used to improve the supply chain performance in every process. As stated by the Sales Director and the Literature (Schrauf & Berttram, 2016), it is apparent that the integration between ERP and handheld machine will allow the sellers to browse for data in real time, create or modify orders, and provide quick turnaround regarding the client’s question. The planning manager also stated that, as the company already implements ERP, past sales, trends and profit generated from each product are presented in a single system allowing the analyst to compare and make optimal decision on the quantity to be produced of each product and how much sales would be generated. In terms of procurement, the literature (Glas & Kleemann, 2016) and interviews had advocated that industry 4.0 can automatically alert the buyers and execute the orders when raw materials are approaching the reordering point. Furthermore, as monitoring the inventory is eliminated, the staff could focus on more value-added tasks such as developing relationship with the suppliers. Similarly, the Manufacturing Director does have similar ideas to Lobo (2015); both imply that the company should automate the production to improve the quality and reduce wastage. Moreover, the data of transformation from raw material to final goods will also be available and the data could be used to improve the processes and solve anticipated problems as well. Moving on to logistics, both literature (Schrauf & Berttram, 2016) and the Logistics Director agreed that the management team could automate the warehouse, optimize the route and track each delivery vehicles.

- Effort Expectancy refers to the easiness in implementing the technology (Venkatesh et al, 2003). Since the company has already installed ERP into the supply chain system, it becomes easier for the company to implement industry 4.0 because the data are organized in a silo. Moreover, they are highly customizable and available in many languages; it becomes easier for the employee to confidently operate the new technology. The literature demonstrated that ERP could provide real-time information and is capable of integrating all business functions to enhance supply chain coordination (Akkermans et. al, 2003). Despite that, it also leads the company to many new challenges, which falls into the similar category with Kidd (1995), which includes;

- Technological Problems:

There are several technological problems that are anticipated to be encounter when implementing industry 4.0. Firstly, both literature and the interview results emphasized that the implementation of industry 4.0 will require a high upfront investment (Schroder 2017). Specifically, as Thailand cannot produce smart machine yet, it will need to purchase at high cost from the developed countries. Moreover, the company will need to procure censors, machines and other components to allow them to be interconnected. Also, there will be additional charges for hiring consulting firms to assist in the projects’ implementation. As a result, the company will not be able to implement the whole process in one go, it will incrementally scale up the development instead.

Secondly, compatibility between the programs also represents a challenge. Concretely, the Procurement Director stated that different suppliers utilize different ERP systems, and sometimes they are not compatible for transferring the data. The company used to face this issue during transferring of the data from previous MRP system to the current ERP system as well (Sriratanaviriyakul, 2013). The IT Director has recommended that system compatibility will become an important criterion when they are recruiting the suppliers.

Thirdly, the company’s data is prone of data theft, which can cause a serious disruption (Yan et. al, 2009). For example, the hacker can install the malware to disrupt the automated production; trade secret might be taken if the data is not encrypted. Moreover, the scientists from Endgame Company could adopt some malware that can avert the anti-virus program (Lerkvaleekul, 2017). The company will need to purchase antivirus suites, hire the full-time specialist to deal with this issue and back up the data into various servers to mitigate against the disruption. Moreover, the elder staff will need to be trained on the phishing email to further secure the system.

Lastly, the changes in technology will also bring about the change in legal framework. As the accountants can access previously hard to find data in real-time via CPS sensor, they are able to calculate the costs necessary to see real production cost. When it becomes prominent, the GAAP or other accounting association may change the account reporting standards hence the accountants will need to follow up on the issues and become more familiar with technological & IT knowledge.

- Organizational problems:

The organizational structure will change as there will be high demand for IT personnel. In fact, many Thai SMEs, including the case study company, lack IT personnel. MD has admitted that, the company has underinvested in attracting highly IT qualified employees and has little knowledge of understanding of the IT management for business. This problem has also been advocated in other developing countries (Pfohl, 2016). Furthermore, millennial workers are more willing to work in multinational companies rather than SMEs because they believe that they not only will gain higher credibility, but they will be paid higher than the rate in medium size firms. Despite that, the HR department is committed to design an interesting employment package to attract such professionals. On the other hand, the blue-collar job will be drastically diminished if not eliminated. As AI takes over their job, only few of blue collar employees will be needed to oversight the progress. Therefore, HR will also need to consider the remuneration package which maintain a balance between their demand and company’s demand.

- Skill Problems:

Industry 4.0 will result in the elimination of some basic jobs; some employees will be moved to work on the more value-added job (Schlotzer, 2015). As the staffs have limited knowledge with their new job, the HR department will need to provide the training to allow the staff to familiarize themselves with their new job and systems.

- Social Factor is the degree that other people or other industry believe that one should implement the technology (Venkatesh et al, 2003). According to the interview with the procurement director, the company is facing various cost pressures such as inflation of raw materials, labor wages and overhead cost. Thus, they will need to reduce these costs to improve the product margin. Additionally the Chinese suppliers are able to produce resinoid product at cheap price therefore many companies within the construction material industry, including KTC, are looking forward to find the new alternatives or improve their systems.

- Facilitating Conditions is the extent that the infrastructure is ready to support and facilitate innovations (Venkatesh et al, 2003). The literatures and the interviews have reflected similar picture for this issue. Specifically, the Thai government currently advocates Thailand 4.0, which will enable firms to get across the middle-income trap, by developing the infrastructure, educational system, initiating tax reduction scheme for innovative SME (The Nation, 2017). Despite the governmental efforts, many interviewees still do not have faith in the government and the situation. Evidently, Thailand has a moderately high corruption index. The private banking institutions become stricter with SME loan due to the increase of NPL (Punyasavatsut, 2008). Moreover, educational institution, especially in rural area, are not doing so well in accordance to PISA (Sondegaard & Lathapipat, 2017). According to the interview with HR Director, the institution must put more emphasis on teaching strategies, research and development, and ensure that the curriculum is standardized throughout the whole country.

Based the literatures and interviews, there is still too much ambiguities on whether to it is time to implement industry 4.0 in Thailand as described in figure 13. To be precise, many Thai SMEs are facing the pressures of increased cost of production hence they are looking for the alternatives. Industry 4.0 seems to be a good idea as it can definitely improve the companies’ performances yet it also comes with many new challenges. The internal challenge includes high upfront investment, lack of IT personnel and system compatibility while the external challenge includes strict policy in loaning, no confidence on government policy and worsening education system. Therefore, all the stakeholders will need to work collaboratively to solve these challenges. The extent to invest in industry 4.0 will be varied by how risk-averse the management team is, how confident companies are in being able to solve new challenges, and how much faith companies have in the fact that external institutions will accomplish their task such as infrastructure and educational issues. This contradicts the literature (UNIDO, n.d.) which advocates that regardless of whether it is a developed or a developing country, one will need to implement industry 4.0 into its supply chain to reduce the cost of production and eliminate all the wastage in long run.

Figure 15: Applying UTAUT model to implementing industry 4.0 at KTC (Pers. Comm., 24 July 2017)

Company B: MACPHIE OF GLENBERVIE, UK

- Performance Expectancy- Industry 4.0 will provide the company with many benefits. For example, RFID allows the company to track the material; automated process reduces the number of staff intervention; censors help to control the temperature in the roasting and mixing process resulting a consistent product quality (SMAS, 2016). The company has also invested in biomass boiler fueled by locally sourced woodchips and two wind turbines, as a result, the company showed a yearly reduction of 2100 tons of carbon emission (ibid.). Additionally, Artic Robot builds pallets of boxes in the sub-zero temperature storage instead of human (Findlay, 2017). This enhances the safety and health of the employees.

- Effort Expectancy- As the company already implemented ERP, the implementation of industry 4.0 becomes easier due to the information transparency among the supply chain. Yet, Industry 4.0 will still create many new challenges, which are to be solved. First, since the robot will take over the job in sub-zero temperature storage, the staff will need to be retrained to be familiar with the new tasks (SMAS,2016). Second, professionals in digitized manufacturing will be in high demand; this represents a challenge for HR to create an employment scheme that will attract them (Ibid.). Third, as industry 4.0 generates huge amount of data, the storage will need to be upgraded or expanded (Castle C-S, n.d.). Lastly, the company will need to spend a high upfront investment in installing the system, which it seems to not pose a problem in this company as the management team advocates innovation (SMAS, 2016).

- Social Factor- The labor cost in developed countries is quite high compared to developing economy. As the company plans to offshore its production back to its origin to be near to the customers, they are forced to find alternatives to solve the problem; industry 4.0 represents a good alternative as it can reduce the number of employees and the level of wastage (Kleindienst & Ramsauer, 2016).

- Facilitating Condition- After Brexit, the UK government will invest in public R&D as it is proved to be successful in Germany, USA and China (Termperton, 2017). The institutions are working with the industries to generate academic and practical contribution to industry 4.0 (SMAS, 2016). Moreover, the external associations, such as Scottish Funding Council, Skill Development Scotland, Scottish Manufacturing Advisory and Service, are consistently monitoring the progress, advocate the problems and continuously provide the action plan for all the stakeholders. This collaborative effort will ensure the progress of facilitating industry 4.0 by the government (Ibid.).

Based on the analysis, the adoption of Industry 4.0 in UK seems to be positive as stated in the literature (UNIDO, 2016). Specifically, many companies in UK are not able to compete with low cost countries thus they are finding new alternative to reduce the operation costs. As the company partly implements industry 4.0, it is evidenced that industry 4.0 can improve the operation performances. Despite facing many challenges, the government, education institutions and external associations are working collaboratively to mitigate the challenges.

Figure 16: Applying UTAUT model to implementing industry 4.0 at Macphie, UK (Adapted from: SMAS, 2016 & Findlay,2017)

Objective 3: To identify the similarities and differences of implementing industry 4.0 in developed and developing countries

The results are different from the literature (UNIDO, 2016), which says both developed and developing countries are facing different situation. In fact, they are facing similar problems except for facilitating condition.

| Similarities | Differences |

|

|

Table 3: Similarities and Differences in adopting industry 4.0 by developed and developing nations

As industry 4.0 is approaching, it is vital for the management team to fully comprehend the concept beforehand and take first-mover advantage. Implementation of industry 4.0 is on the discretion and risk aversion of the management team. Based on case analysis, it can be deduced that industry 4.0 will result in operation improvement and it can be used in various functions in the supply chain system. In term of effort expectancy, SMEs in both countries utilize ERP system to organize and oversight the supply chain, which make it easier to implement industry 4.0. However, they are expected to face with universal challenges such as Investment scarcity, System Compatibility, Employees and Cyber Security Threats. In addition, both companies also face with the pressure to increase the quality and decrease the operation cost. The only difference between them seems to be the faith in the government. In UK, the government vowed to increase the public R&D fund to generate the knowledge and innovation for public usage. The external associations will monitor, criticize and make action plan for the stakeholders. These collaborations will improve the confidence of UK people towards the industry 4.0 progress. While in Thailand, the government promotes Thailand 4.0, which aims to improve IT infrastructure, education system and taxation. Yet, the citizens do not have faith in the government to be able to solve the problem as evidenced by the banks become stricter with loaning to SME due to high NPL; and education in Thailand is worsening.

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Supply Chain"

A Supply Chain is a system in place between companies and their suppliers, from producing a product to distributing it ready to be sold. An effective and smooth running supply chain can contribute to the successful running of a business.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: