Health and Safety Case Study: KunShan Explosion and Cancer at Samsung

Info: 6973 words (28 pages) Dissertation

Published: 5th Jan 2022

Tagged: Health and SafetyCancer

Table of Contents

Click to expand Table of Contents

Section 1: Literature Review

1.1 Definition of Employment relation:

1.2 The importance of Employment relation:

1.3 Health and safety

Section 2: Case Study

2.1 KunShan Explosion

2.1.1 Introduction of 2014 KunShan Explosion

2.1.2 Background

2.1.3 Summary causes

2.2 Samsung Workers Have Deadly Cancer

2.2.1 Introduction of Samsung Workers Have Deadly Cancer

2.2.2 Causes of cancer in Samsung

Section 3: Independent Analysis

3.1 Solution and Evaluation of KunShan Explosion

3.1.1 Improving the working environment

3.1.2 Avoid Working Overtime

3.1.3. Using protective equipment

3.2 Solution and Evaluation of Samsung Case

References

Appendices

Table of Figures

Figure 1: The actors affect on Employment Relation

Figure 2: Guest and Conway model of cause and consequences of the psychological contract

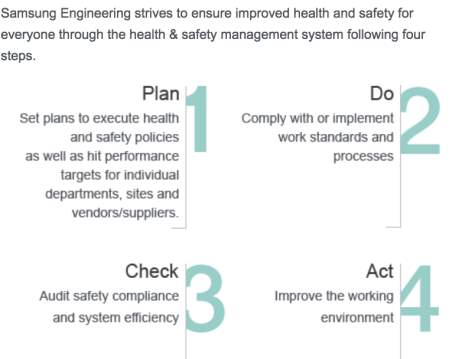

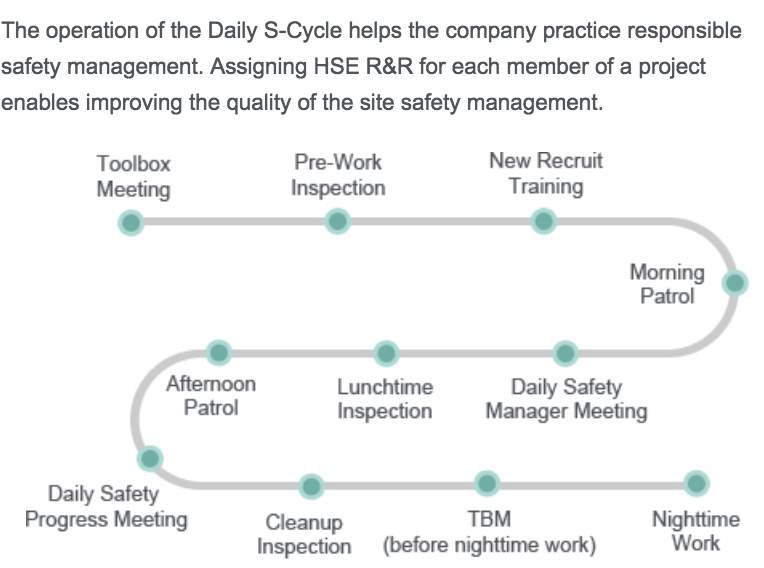

Figure 3: Health and safety process (Source: Samsungengineering.com,2018)

Figure 4: Health and safety management (Source: Samsungengineering.com,2018)

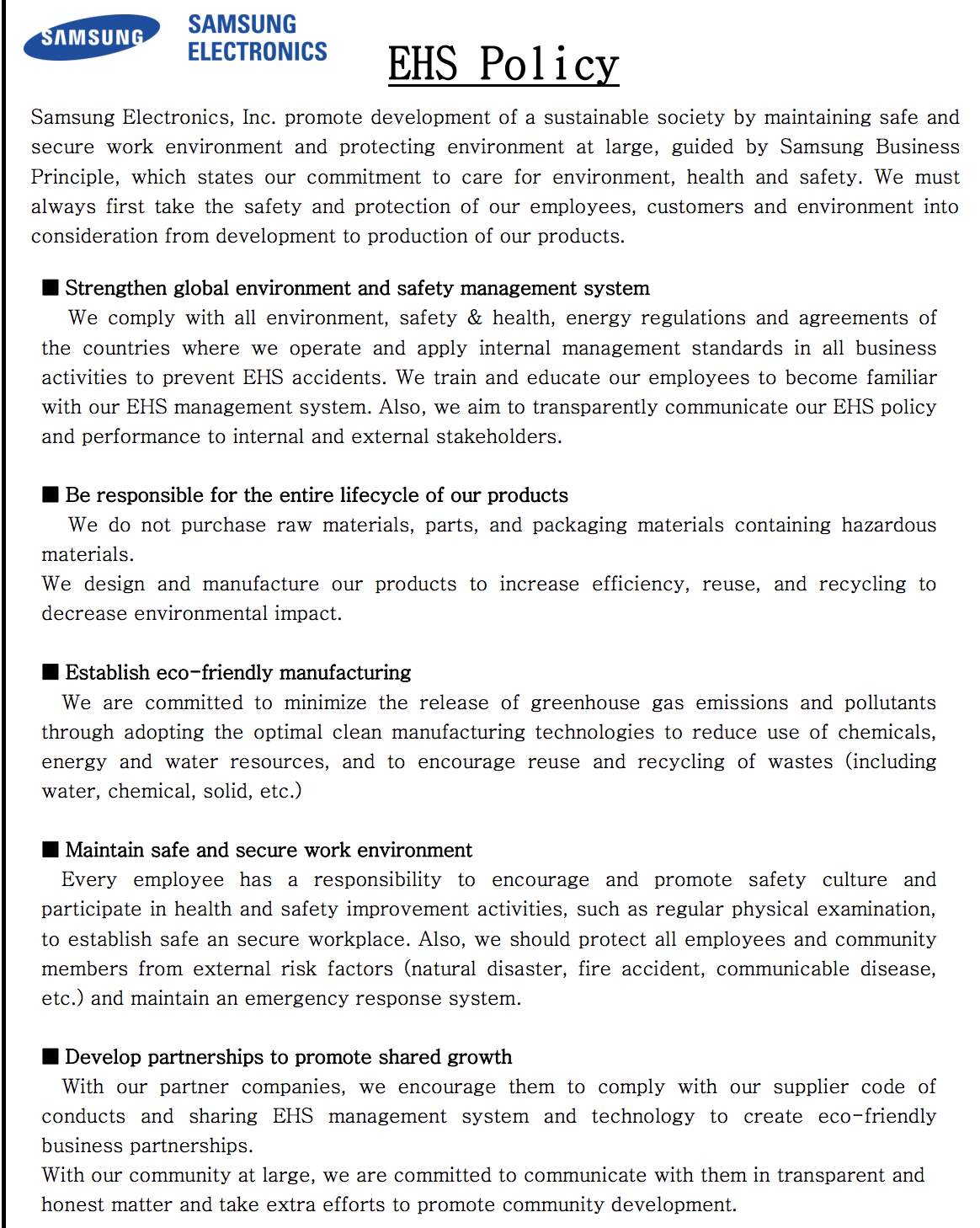

Figure 5: Samsung’s health and safety policy (Samsung.com,2018)

Figure 6: KunShan factory explosion, XinHua

Figure 7: KunShan Explosion, XinHua

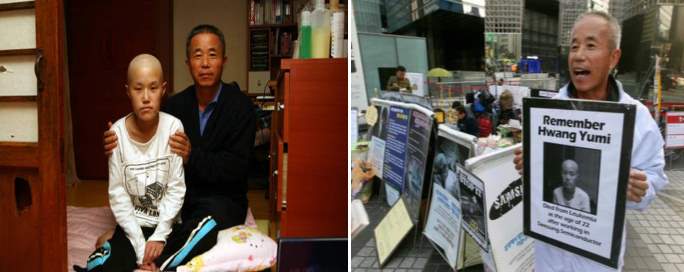

Figure 8:Hundreds of Samsung workers have deadly cancer, Baomoi

Figure 9:Number of Samsung Electronics employees worldwide from 2009 to 2017 (in 1,000s) (Source: Samsung)

Figure 10: Safety corrective action request system to create HSE issues database(Source: Samsungengineering.com,2018)

Figure 11: Samsung’s 10 safety rules (Source: Samsungengineering.com,2018)

Figure 12: Samsung safety training (Source: Samsungengineering.com,2018)

Figure 13:Financial summary by division (Source: Samsung Electronics 2015 Business Report )

Figure 14: HSE Sustainability policy (Source: Samsungengineering.com,2018)

Section 1: Literature Review

1.1 Definition of Employment relation

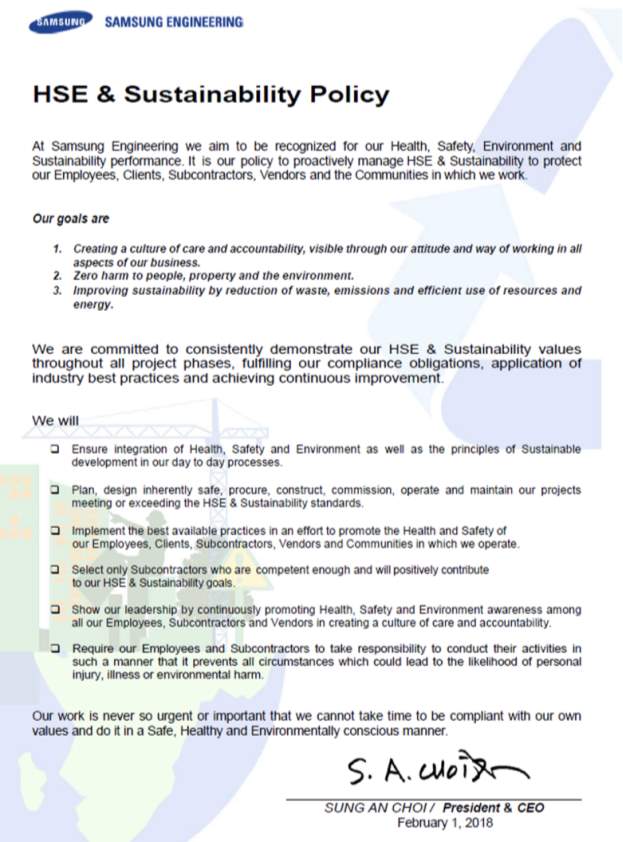

According to Dave Bookbinder, author of Return on Individuals: “The value of a business is a function of how well the financial capital and the intellectual capital are managed by the human capital. “You’d better get the human part right.” A thriving and sustainable economy requires the elements of finance, science technology, resource and labour. Among them all, human is always important to the success of one’s business. In the increasingly competitive business environment, demand is much higher for both sides.

To maintain a sustainable business, Employment Relation should be in great concern. So, what is employment relation? According to (Salmon, 2000): “Employment relation is about dealing with the conduct and regulation, managing the relationship between employees and the company and with each other on a micro level, and also between union and the company in a macro-approach.”

It influences nearly every Human Resource decisions of the firm and it deals with political, economic, technological, legal and social context. Another explanation of Employment relation is “The relationship when employees sell their intellectual and physical power in exchange for salary and benefits, and the company pays employees to get products or service” (Dibben P., 2011). It helps to clarify and manage effectively and fairly, and to reduce risk and resolve conflicts when occurred through agreements.

The agreements cover these specific interests: Code of Conduct, Confidentiality, Conflict of Interest, Working conditions, Job Description, Working outcome, Attendance, Working hour, Termination, Recruitment, Compensation, Performance Management, Learning and development, Benefits and Eligibility, Overtime, Privacy, Information, Leave, Vacation, Disability, Jury Duty, Formal complaint process, Disciplinary, Discrimination and Harassment, Health and Safety.

Figure 1: The actors’ effect on Employment Relation

1.2 The importance of Employment relation

According to (Dibben P., 2011), Employment relation helps to control, adapt and adjust the employment relationship by rules binding both parties while maintaining the company’s culture and performance, forecasting and resolving conflicts and developing employee engagement. It helps to create a fair, effective and consistent working communication and interaction between managers and employees, as well as being a guideline for employees to know how they are expected to behave, and for supervisors to assess employee’s performance. As employer relation involves all the potential issues in the workplace like ethics, justice, clarity, equality and sustainable working environment, it could help to fulfil the needs of both parties, designing wages, working conditions that suit with economic and social context, minimizing conflict and facilitating the company with condition and practice that is competitive to the economy. In return, employees are becoming more loyal, satisfied and motivated to contribute to the success of the company.

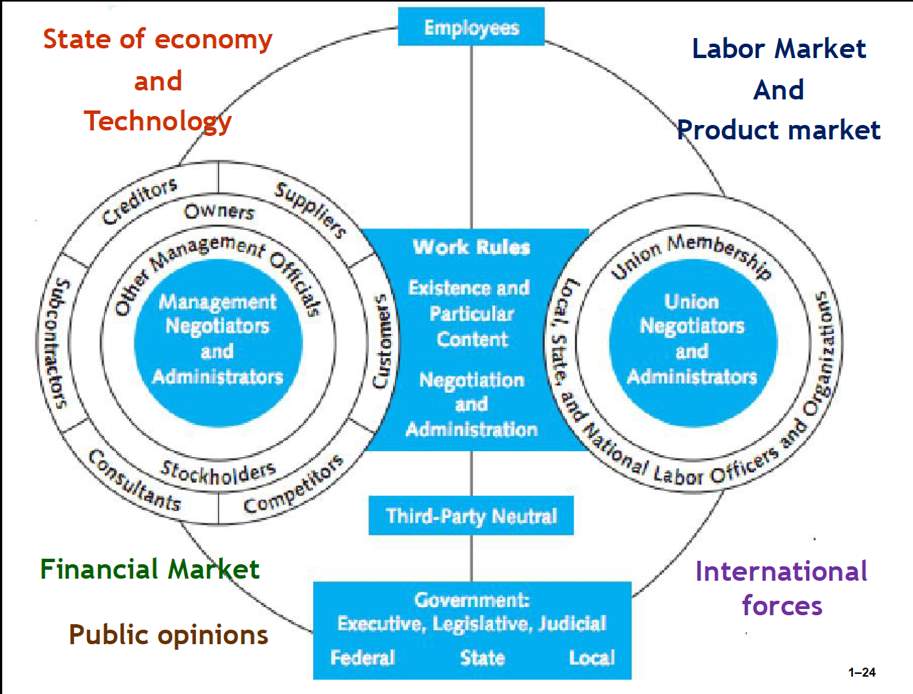

Figure 2: Guest and Conway model of cause and consequences of the psychological contract

1.3 Health and safety

Health and Safety is one of the most significant functions of Human Resources and employment relations. Safety is referring to the physical body is able to move normally, healthy and away from danger and injury without emotional issues and psychological (Foot et al., 2016). Health can be defined as a healthy body including physical and mental health and there are no illnesses or injuries that interfere with normal physical activity (Foot et al., 2016). Furthermore, the health and safety of employees is of great significance to the company.

First of all, employees’ health and safety management is an effective method to reduce and control medical expenses. By implementing health and safety management, enterprises can save the loss of human resources and reduce health care related expenses. It could help to minimize the risks to the employees and their dependants (Foot et al., 2016).

Secondly, health and safety management of employees effectively improves employee’s working hour. This is because it can effectively reduce sick leave and health-related leave (Zhu, 2013).

Thirdly, health and safety are the basic human capital needs, and ensuring the health and safety management of employees can improve the output efficiency of other capital inputs, and building a positive brand image as an enterprise (Muskin, 1962). According to Zhu (2013), health and safety management helps to improve the physical quality of employees, make them energetic and productive, reduce the work inharmonious caused by illness and absence and affect the progress of work. At the same time, it also reflects the concern for the health of employees, improve the sense of belonging and work enthusiasm of employees and improve work efficiency (Muskin, 1962).

Last but not the least, it can improve the quality of present and future human resources and directly promote the growth of present and future productivity (Zhu, 2013). Thus, the organization must manage the safety and health of the workplace in order to ensure the normal operation and efficiency of employees.

In conclusion, creating a safe and happy working environment is the morale and legal responsibilities of the employers, and also of every employee who work under contract. However, organisations have to adhere to these principles for health and safety management. First of all, the organisation should follow the relevant laws and policies of the state on the health and safety of employees and suitable for the nature and scale of the risks faced by the enterprise or organization. Furthermore, the organization should formalize the management plan and carry out according to the document and should be subject to periodic review and evaluation by the employee and manager (Zhu, 2013). Indeed, enterprises should take into account the actual circumstances of the company, including factors such as the nature of the industry and the corporate culture when setting up management programs.

To summarize, safety and health are an inseparable part of the employment relations. Health and safety management plan is a Win-Win between employee and company. Therefore, it is particularly important to study the health and safety of organization. This article will use two examples to analyze the health and safety of enterprises.

Section 2: Case Study

2.1 KunShan Explosion

2.1.1 Introduction of 2014 KunShan Explosion

KunShan ZhongRong factory explosion accident was at 7am on August 2, 2014. A serious dust explosion occurred in the car wheel polishing second workshop of Zhongrong Metal Products Co., Ltd. in Kunshan City, Jiangsu Province, China. There were almost 264 people in the workshop at the time of the accident, and 75 people were killed on the day of the accident. As of December 30, 146 people were killed and almost 118 people were injured.

2.1.2 Background

+ Unites incident: Kunshan City in-Metal Products Co., Ltd. was founded in 1998, Taiwan-funded enterprises, the main production electroplating alloy wheels, is the United States General Motors designated supplier. Plant area of fifty thousand square meters, a total of about 450 employees.

+ Accident Background: Shortly before the accident, the start-up time of the incident workshop was advanced from 8:00 am to 7:00 pm, and workers often worked 11 hours in a row. The workshop has serious dust. The dust removal equipment only has air blowers, lacks spray dust removal equipment, and no special person is responsible for dust removal. It is only when the months are not very busy that the workers are allowed to clean the air duct. In addition, accident coincided with weekend, due to the double pay overtime, so high casualties. Moreover, the city’s work safety regulator said it had repeatedly warned the factory that some potential hazards of the explosion, but it was ignored. Furthermore, the employee reported the pollution problem, but the factory has been ignoring.

2.1.3 Summary causes

After investigation, the direct cause of the explosion was found to be caused by aluminum powder in case of fire. At the same time, the company has long-term safety hazards and damage to employees’ health. Furthermore, there are some potential dangers and causes of the accident are:

- The factory building is not constructed according to the regulations, and the double-layer production workshop is illegally constructed. The building spacing is not enough;

- The production process route is too tight,

- The dust removal equipment does not design an independent dust suction device for each post according to the regulations. All electrical equipment in the workshop does not meet the requirements of explosion-proof requirements.

- Insufficient dust removal capacity. Did not clean the dust of the pipeline in time.

- The enterprise safety production system and measures are not perfect.

- There is no safety training for workers, and there are no fire-retardant and anti-static labor protection products as required. Violation of labor regulations and overtime work.

- The local government has neglected the supervision and the hidden dangers have not been resolved for a long time.

2.2 Samsung Workers Have Deadly Cancer

2.2.1 Introduction of Samsung Workers Have Deadly Cancer

Samsung, the largest producers of electronic devices, was founded in 1938 by Lee Byung-Chull. It concentrates on the production industry electronics, including semiconductor, memory chips, integrated systems and appliances. Samsung has become one of the most popular brands of producers, which produces around a fifth of total exports in South Korea.

By the end of 2015, ‘221 Samsung employees suffered from cancer and a rare condition after the company’s work, of which 75 were fatal’ said by Banolim. The most typical example is the case of Hwang Sang-gi’s daughter Yu-mi, who died in 2007 at the age of 22. Due to the chemicals in the Samsung’s factories in south of Seoul, Yu was attacked by a disease called acute myeloid leukemia. Yu-mi’s father Sang-gi became one of the founders of Banolim, he spent seven year to shed light on the use of carcinogens in the Electronic equipment factory, especially semiconductor equipment factory.

2.2.2 Causes of cancer in Samsung

Internal factor—— Carcinogen

Luan (2012) pointed that Huffington Post believed that the chemicals used to process wafers in chip factories of Samsung were linked with cancer. The World Health Organisation (WHO) and the International Agency for Research on Cancer (IARC) (NHS, 2015) have reported that there are estimated about 7% to 19% of cancers are because of the toxic material contact in daily life. As a result, the chemicals used in Samsung’s factories would seem to be the carcinogen. These chemicals may have the potential to make cells become cancer cells.

External factor—— Work Environment

People who work in the Samsung factories are in a closed room, with air conditioning system to ensure the products are clean. This kind of work environment will help the dangerous air to escape anywhere and therefore it cannot be exhausted. This is because the worker will not be poisoned by the toxic gap from chemicals. However, the workers cannot get the fresh air when they are working in the closed room.

Potential factor—— The temptation of money

According to VTC NEWS (2014), the workers had not filed a complaint or sued Samsung; although there are 19,000 workers at the Giheung factory were ill. The reason is that the company had compensated huge number of money to withdraw the suit and keep them silent. With the temptation of money, this event may probably disappear in the public, so that the company will ignore the death of toxic workers.

Section 3: Independent Analysis

According to (Michael Amstrong and Stephen Taylor, 2017), Top management should take great concern in establishing Health and safety policies. The complete policy should consist of three parts:

General statement

This is the declaration of importance and show the efforts of the company to comply the procedures to meet the standard with the law and legislation, in this part the company should also states the responsibilities of top management in assuring the ultimate standard of health and safety in the company, and the contacts and roles of each safety representatives and medical officers.

Description of means being implied

Conducting risk assessment

Identify different possible hazards in the workplace and the risks that could be attached to the hazards in order to prevent them and take control measures. There are two main types of risks assessment: qualitative (subjective and generalized analysis) and quantitative (using data to estimate). When conducting assessment companies should consider the risks that could be happen to employees and also visitors (outsourcing workers, guests and contractors). And then it should lead to practical actions to eliminate the hazards (protective equipment, adapt working procedures, change of chemicals, using barriers and warning system etc.)

Health and safety reviews and audits

Companies need to get health and safety advisor committees, board of management and employees to get involved in this stage, or they can outsource agencies to carry out independent audits. The audit should ensure the policies, procedures and practices align with the legal requirements, that everyone in the company is committed to it and the practices need to be clearly communicated and trained internally. The outcome of this stage is the assessment of priorities and costs of the program to get approval.

Health and safety inspection

This stage is to define any faults or operational errors that could cause accident and create a report checklist for closer monitoring

Guidelines for implementing

After carrying out the program, it is essential to measure the effectiveness using the two methods of:

+ The frequency rate: (number of injuries/numbers of working hour) * 100,000

+ The incident rate: (number of injuries/ number of employees in that period) * 1,000

3.1 Solution and Evaluation of KunShan Explosion

3.1.1 Improving the working environment

Due to the accident workshop dust removal system for a long time not as prescribed cleaning, aluminum dust accumulation and lead to dust removal system and workshop series of explosions. According to Zhu (2013), company needs to ensure the clean and safe of working environment for employees. Thus, it’s necessary to improve the working environment.

First of all, Kunshan City in-Metal Products Ltd should control the concentration of combustible dust in combustible materials, such as Aluminum dust, the equipment with good sealing performance can be used in production, processing and storage. Furthermore, if the equipment, such as silo and hoist, has powder leakage and other phenomena to timely maintenance, should be repaired in time to reduce or avoid dust dispersion as far as possible.

Thirdly, the factory needs to installation of effective ventilation and dust removal equipment, such as dust shaker, and strengthening of cleaning work in order to eliminate the flammable dust suspended in the air and reduce the concentration of the combustible dust in the combustible substance. Indeed, to ensure that the combustible dust is not within the limit of explosion concentration, and to prevent the explosion of combustible dust fundamentally.

Last but not the least, factory have to eliminate ignition sources in the workplace. By controlling and protection of ignition source in the workplace to avoid explosion of ignition source and combustible material.

3.1.2 Avoid Working Overtime

According to articles 36 (State Working Hours System), 38 (The minimum guarantee for rest days) and 42 (Prohibition of illegal extension of working hours) of the Labour Law of the People’s republic of China (2014), the working hours of workers are not more than eight hours per day and the average weekly working hours are not more than forty-four hours, the employer need to ensure that the labourer rests at least one day per week and the employer shall not extend the working hours of the workers in violation of the provisions of this Law. The Kunshan factory seriously violated the provisions of the Labor Law.

Therefore, the owner and manager of the factory must create a new work schedule in accordance with the law, to ensure the legal rest time of the staff. In addition, the local government to carry out strict supervision. Furthermore, the government accepts and encourages employees to inform any illegal situation and provide corresponding rewards, make sure employee voice can be concerned and valued. If the employee voice cannot be responses by government or company, then the employee can use social media to expose any illegal and unequal treatment that would endanger the health and safety of physiology and psychology.

3.1.3. Using protective equipment

In order to protect the health of workers who are working in the dust, they should wear the protective clothing. The protective garments are used to enhance worker safety, they also have some negative impacts on worker performance, heat stress as an example (Adams, Slocum and Keyserling, 1994). As a result, it would seem that changing the working environment of Kunshan Factory can be a fundamental method to solve the health problem. Simultaneously, the workers also need to take some trainings about how to protect themselves in the emergency. From Robson, Stephenson and Schulte et al. (2012), the occupational health and safety had shown positive effects on behaviours. So, the Kunshan Factory should focus on the health and safety training and changing the working environment. The following discussion will pay more attention about the working environment and overtime working in Kunshan Factory.

3.2 Solution and Evaluation of Samsung Case

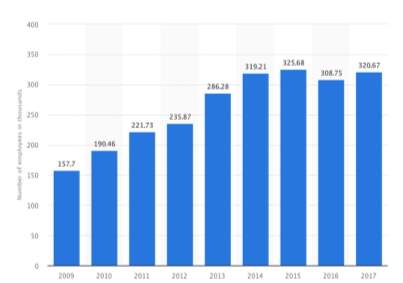

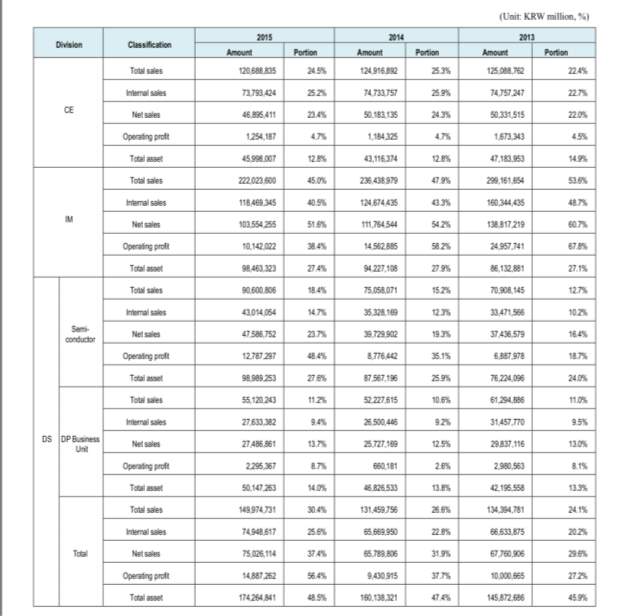

Samsung was and is still a successful company. However, in recent years especially in 2015, their sales dropped. Before in 2015, their sales were higher. For example, in 2013 Samsung total sales were at 125,088,762 krw million, and 124,916,892 krw and 120,688,835 krw million in 2014 and 2015 respectively (SAMSUNG ELECTRONICS Co., Ltd., 2015). See figure 13. Therefore, Samsung’s significant sales drop had an impact on the human resources as in the factory workers in South Korea. The problem roots from the case that many employees suffered from deadly cancer which happens to be a rare condition in 2015 (Baomoi.com, 2016). Over a quarter of labours have died from the rare disease (Baomoi.com, 2016). After the incident which was in 2015, there was staff turnover.

In the year 2015, the number of Samsung Electronics staff who worked worldwide was at 325,680 (Statista, 2018). However, 308,750 employees worked at Samsung Electronics in the year 2016 globally (Statista, 2018). See figure 9. Therefore, the employment relations in regarding Health and Safety was not in place. Many people did not trust Samsung as they became aware of the incident and worried about how workers could be treated in the future and if more equipment would be provided in regard to health and safety for the future coming. Samsung needs to improve their employment relations towards employees as it will benefit both sides.

Without having good employment relations, employers would not treat their employees ethically, for instance, providing health and safety at work. In order to prevent any major happenings, Samsung employers should provide surveys for employees which would lead to having communication as well as receiving feedback (Vredenburgh, 2002). This would help them to find out if there are any signs of problems which employees put in the survey (XpertHR, 2018). The survey should also give a reflection on how employees feel at work in general if they put in the survey genuinely.

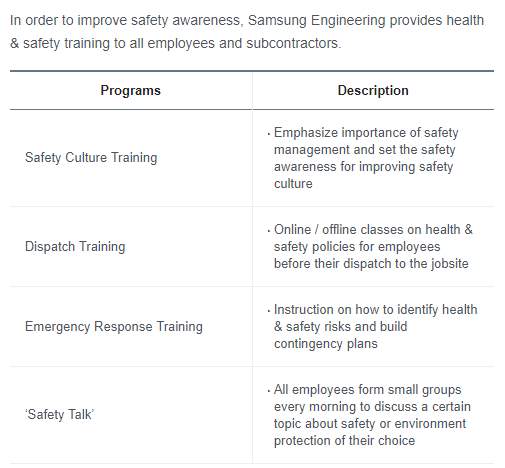

Once employers have identified the problem what employees put in the survey then they can take measures in solving the problem. Besides, Samsung employers should concentrate on providing safety training (Vredenburgh, 2002). Vredenburgh (2002) suggest that employees need to have training for their safety and health. This is because by receiving training of safety Samsung employers will be able to identify the potential accidents that could occur at work and provide measures or solutions to prevent serious injuries or deaths.

Another suggestion would be that Samsung should let or get their employees involved in terms of the organisational issues. Therefore, this would lead to worker participation (Vredenburgh, 2002). Vredenburgh (2002) also proposes that employees are the best people to ask in regard to their concerns at work. This is because they are the part and heart of the organisation which will impact on their work performance. By listening to employees; concerns employers can do something about the circumstances. This highlights that employers have the choice to ensure that staff voices are heard. By giving the opportunity to employees’ involvement of Samsung they will feel more comfortable to do their job effectively without much interference unless guidance is needed from them (Cohen and Cleveland, 1983 in Vredenburgh, 2002).

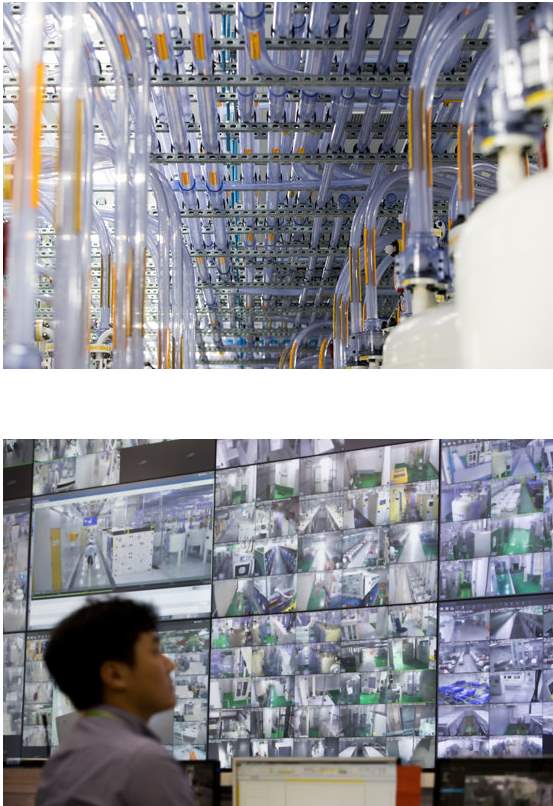

Samsung try to use non-hazardous materials. However, manufacturing semiconductors sometimes involve with hazardous chemicals. Samsung has operated the most advanced chemical management system and stringent policy. Before being delivered to facilities, chemical substance is being analyzed on physical and chemical characteristic. The process of health and safety controls on storage, use, recycling and disposal is being strictly regulated. Chemicals are stored outside the cleanroom and are transferred directly to the equipment without contacting workers. They keep the exposure standard to 1/10 of legal requirements. Samsung continuously seek for enhancement in chemical monitoring, air and water quality monitoring system, and they have maintained the ISO 14001 and OHSAS 18001 certifications for effective safety control (Samsung Semiconductor, 2018).

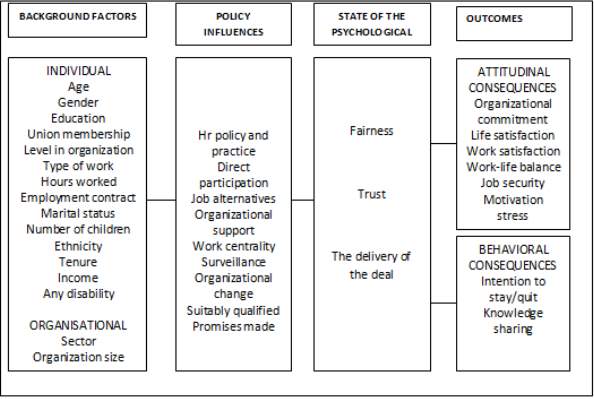

Samsung has already made policies in regard to their health and safety for their employees which is the right thing to do. See figure 5. However, the policies may not have been effective. This is because employees were not protected (Baomoi.com, 2016). Therefore, they got sick or died from the deadly cancer (Baomoi.com, 2016). This shows that writing policies are equally important as implementing their actions what they are going to carry out in order to avoid contradiction eventually. Although Samsung claimed that they tell employees how to be protected at work (Samsung, 2016) they still faced consequences of the deadly cancer. They have ignored workers needs for instance, providing training in order to ensure that terrible incidents will be reduced.

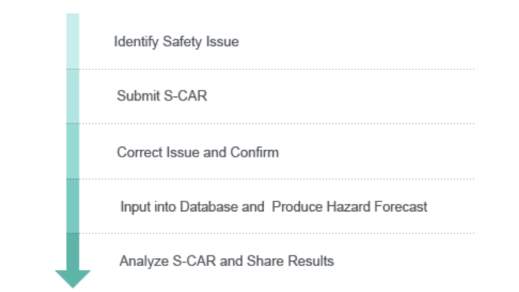

Figure 3: Health and safety process (Source: Samsungengineering.com,2018)

Figure 4: Health and safety management (Source: Samsungengineering.com,2018)

Figure 5: Samsung’s health and safety policy (Samsung.com,2018)

References

Amuedo-Dorantes, C., 2002. Work safety in the context of temporary employment: The Spanish experience. Industrial and Labor Relations Review 55, 262–285. doi:10.1177/001979390205500204

Arnold, J., Randall, R. et al. (2016), 2018. work psychology 1–33

Ashiru, O. a, Odusanya, O.O., 2009. Fertility and occupational hazards: review of the literature. African journal of reproductive health 13, 159–165.

Báo điện tử Tiền Phong. (2018). Tôi đi làm công nhân Samsung: Sự thật những tin đồn. [online] Available at: https://www.tienphong.vn/xa-hoi-phong-su/toi-di-lam-cong-nhan-samsung-su-that-nhung-tin-don-1250421.tpo [Accessed 17 Oct. 2018].

Benavides, F.G., Benach, J., Mustard, C.A., Delclos, G.L., Catot, N., Amabile, T.M., 2006. Associations between temporary employment and occupational injury: what are the mechanisms? Occupational and environmental medicine 63, 416–21. doi:10.1136/oem.2005.022301

Blank, V.L.G., Andersson, R., Lindén, A., Nilsson, B.C., 1995. Hidden accident rates and patterns in the Swedish mining industry due to involvement of contractor workers. Safety Science 21, 23–35. doi:10.1016/0925-7535(95)00004-6

Blank, V.L.G., Laflamme, L., Andersson, R., 1997. The impact of advances in production technology on industrial injuries: A review of the literature. Safety Science 26, 219–234. doi:10.1016/S0925-7535(97)00044-1

Cellar, D.F., Yorke, C.M., Nelson, Z.C., Carroll, K.A., 2004. Relationships between five factor personality variables, workplace accidents, and self-efficacy. Psychological Reports 94, 1437–1441. doi:10.2466/PR0.94.3.1437-1441

Cioni, M., Savioli, M., 2016. Safety at the workplace: accidents and illnesses. Work, Employment and Society 30, 858–875. doi:10.1177/0950017015590759

CIPD, 2016. Absence Management – Annual Survey Report 2016 [WWW Document]. CIPD. doi:0683

CIPD, 2016. Absence Management Survey – Private Sector 2016. doi:0683

CIPD, 2016. Absence Management Survey – Public Sector 2016. doi:0683

CIPD, 2018. Health & Wellbeing at Work [WWW Document]. URL https://www.cipd.co.uk/Images/health-and-well-being-at-work_tcm18-40863.pdf

Developed Master Li(masterlijf#hotmail.com), 3. (2018). The reasons for the explosion in Kunshan and how to protect it. [online] Cz-ex.net. Available at: http://www.cz-ex.net/xyzx/ksbzdyyyjz_1.html [Accessed 16 Oct. 2018].

Fabiano, B., Currò, F., & Pastorino, R. (2004). A study of the relationship between occupational injuries and firm size and type in the Italian industry. Safety Science, 42(7), 587–600. https://doi.org/10.1016/j.ssci.2003.09.003

Fortin, B., Lanoie, P., LaPorte, C., 1996. Unemployment insurance and the duration of workplace accidents. Canadian Journal of Economics April, 17–24. doi:10.2307/135953

Foot, M., Hook, C., Jenkins, A. (2016) Performance management and performance appraisal. In health, safety and wellbeing. 7th edn., pp. 218-219. Harlow: Pearson Education Limited.

Goldberg, A.I., Dar‐El, E.M., Rubin, A.E., 1991. Threat perception and the readiness to participate in safety programs. Journal of Organizational Behavior 12, 109–122. doi:10.1002/job.4030120204

Khanzode, V.V., Maiti, J., Ray, P.K., 2012. Occupational injury and accident research: A comprehensive review. Safety Science. doi: 10.1016/j.ssci.2011.12.015

Kitt, M., Howard, J., 2013. THE FACE OF OCCUPATIONAL SAFETY AND HEALTH: 2020 AND BEYOND. Public Health Reports (1974-) 128, 138–139.

Martinello, F., Meng, R., 1992. Workplace Risks and the Value of Hazard Avoidance. The Canadian Journal of Economics 25, 333. doi:10.2307/135867

McCallum, R., Schofield, T., Reeve, B., 2012. The Role of the Judiciary in Occupational Health and Safety Prosecutions: Institutional Processes and the Production of Deterrence. Journal of Industrial Relations 54, 688–706. doi:10.1177/0022185612454956

McLain, D.L., 1995. Responses to health and safety risk in the work environment. Academy of Management journal. Academy of Management 38, 1726–1743. doi:10.2307/256852

Muskin, S. J. (1962) Health as an investment. Journal of Political Economics, 70, pp. 129-157.

Nenonen, S., 2011. Fatal workplace accidents in outsourced operations in the manufacturing industry. Safety Science 49, 1394–1403. doi:10.1016/j.ssci.2011.06.004

News, V. (2018). Samsung làm ngơ vụ công nhân tử vong vì nhiễm khí độc – VTC News. [online] VTC news. Available at: https://vtc.vn/samsung-lam-ngo-vu-cong-nhan-tu-vong-vi-nhiem-khi-doc-d152727.html [Accessed 17 Oct. 2018].

Olson, S.H., 1979. An ecology of workplace hazards ( Canada). Economic Geography 55, 287–308. doi:10.2307/143162

Quinlan, M., Muntaner, C., Solar, O., Vergara, M., Eijkemans, G., Santana, V., Chung, H., Castedo, A., Benach, J., 2010. Policies and interventions on employment relations and health inequalities. International journal of health services : planning, administration, evaluation 40, 297–307. doi:10.2190/HS.40.2.i

Samsung, 2016. Employee Health And Safety At Semiconductor Facilities. [online] Available at:

South China Morning Post. (2018). Kunshan explosion factory ignored several danger warnings, says regulator. [online] Available at: https://www.scmp.com/news/china/article/1565751/kunshan-explosion-factory-ignored-several-danger-warnings-says-regulator [Accessed 16 Oct. 2018].

S2 health-and-well-being-at-work-infographic-1_tcm18-40892, 2AD.

Tom Redman, A.W., 2008. Contemporary Human Resource Management: Text and Cases, 3rd ed.

VnExpress. (2018). Cứ 100 nhân viên làm điện thoại Samsung thì có 80 người Việt – VnExpress Kinh Doanh. [online] Available at: https://kinhdoanh.vnexpress.net/tin-tuc/doanh-nghiep/cu-100-nhan-vien-lam-dien-thoai-samsung-thi-co-80-nguoi-viet-3398628.html?ctr=related_news_click https://kinhdoanh.vnexpress.net/tin-tuc/doanh-nghiep/samsung-viet-nam-chua-tung-co-cong-nhan-nao-bi-phoi-nhiem-hoa-chat-3675420.html [Accessed 17 Oct. 2018].

Việt Nam Mới. (2018). Lật tẩy chuyện đáng sợ của công nhân sau khi rời Samsung | Việt Nam Mới. [online] Available at: https://vietnammoi.vn/lat-tay-chuyen-dang-so-cua-cong-nhan-sau-khi-roi-samsung-37116.html [Accessed 17 Oct. 2018].

VnReview.vn. (2018). Nhà máy sản xuất chip của Samsung gây bệnh ung thư – VnReview – Tin nóng. [online] Available at: https://vnreview.vn/tin-tuc-xa-hoi-so/-/view_content/content/360804/nha-may-san-xuat-chip-cua-samsung-gay-benh-ung-thu [Accessed 17 Oct. 2018].

Wachter, D.S. and T. von, 2016. Job Displacement and Mortality: An Analysis Using Administrative Data. Oxford University Press 124, 1265–1306.

Williams, M. (2018). China factory explosion kills scores. [online] the Guardian. Available at: https://www.theguardian.com/world/2014/aug/02/china-factory-explosion-kills-scores-shanghai [Accessed 16 Oct. 2018].

Worrall, J.D., Butler, R.J., 1983. Health conditions and job hazards: Union and nonunion jobs. Journal of Labor Research 4, 339–347. doi:10.1007/BF02685341

Xinhuanet.com. (2018). 昆山爆炸事故已致65人死亡150多人受伤_图片频道_新华网. [online] Available at: http://www.xinhuanet.com/photo/2014-08/02/c_126825403.htm [Accessed 16 Oct. 2018].

Zhu, B., Zhu, Y. (2013) A Preliminary Study of Employee Health Management from the Perspective of Human Capital Investment. Journal of Nanjing University of Science and Technology, 26(5), pp.35-40.

MANAGING THE PSYCHOLOGICAL CONTRACT. (2018). [image] Available at: https://writepass.com/journal/2015/04/managing-the-psychological-contract/ [Accessed 17 Oct. 2018].

Baomoi.com, 2016. Samsung Ignored The Deaths Of Toxic Workers. [online] Available at: https://baomoi.com/hang-tram-cong-nhan-samsung-mac-benh-ung-thu-chet- nguoi/c/18437053; [Accessed 21 October 2018].

SAMSUNG ELECTRONICS Co., Ltd., 2015. 2015 Business Report. [online] Available: http://images.samsung.com/is/content/samsung/p5/sg/ir/docs/2015_business_quarter04 [Accessed 21 October 2018].

Statista, 2018. Number Of Samsung Electronics Employees Worldwide From 2009 To 2017 (In 1,000S). [online] Available at: https://www.statista.com/statistics/236919/number-of-samsung-electronics-employees-worldwide [Accessed 21 October 2018].

Vredenburgh, A., 2002. Organizational safety: Which management practices are most effective in reducing employee injury rates? Journal of Safety Research, 33(2002), pp.259–276.

XpertHR, 2018. Design A Staff Engagement Survey. [online] Available at: https://www.xperthr.co.uk/tasks/design-a-staff-engagement-survey/150653/?keywords=value+of+employment+relations [Accessed 22 October 2018].

Adams, P. S., Slocum, A. C. and Keyserling, W. M. (1994) A Model for Protective Clothing Effects on Performance. International Journal of Clothing Science and Technology, 6(4), pp.6-16.

Robson, L., Stephenson, C., Schulte, P., Amick, B., Irvin, E., Eggerth, D. et al. (2012). A systematic review of the effectiveness of occupational health and safety training. Scandinavian Journal of Work, Environment & Health, 38(3), pp. 193-208

Samsung Semiconductor. (2018). Our commitments on responsible chemicals management. [online] Available at: https://www.samsung.com/semiconductor/minisite/EHS/commitment/ [Accessed 23 Oct. 2018].

Samsungengineering.com. (2018). Samsung Engineering. [online] Available at: http://www.samsungengineering.com/sustainability/hse/health/suView [Accessed 23 Oct. 2018].

Samsung.com. (2018). EHS Policy. [online] Available at: https://www.samsung.com/us/smg/content/dam/samsung/sg/aboutsamsung/2017/environment/pdf/environmnet-health-n-safety-policy-en.pdf [Accessed 23 Oct. 2018].

Appendices

1. The 8.2 KunShan Explosion

The 2014 Kunshan explosion was a dust explosion that occurred at Zhongrong Metal Production Company, an automotive parts factory located in Kunshan, Jiangsu, China, on 2 August 2014. The explosion killed 146 workers and injured 118 others (Xinhua News Website, 2014).

Figure 6: KunShan factory explosion, XinHua

Event

A massive explosion occurred at the factory at 7:37 a.m. At the time, more than 260 people were present, which was more than the usual number of employees working since overtime wages were doubled during the weekends.44 people died at the scene of the explosion, while another 31 died at local hospitals. Five hospitals in Kunshan and nearby Suzhou treated over 180 wounded. Almost all workers were seriously burned or injured. It is believed the explosion may have been caused by flames igniting metal polishing dust (South China Morning Post Website, 2014).

Figure 7: KunShan Explosion, XinHua

2. Hundreds of Samsung workers have deadly cancer

According to Banolim, the main advocacy group for infected workers, out of 221 Samsung workers suffering from cancer, and rare disease after working at the company, 75 people died last year. (Baomoi website, 2016)

Event

The most typical example is the case of Hwang Sang-gi’s daughter Yu-mi who died in 2007 at the age of 22 due to a blood cancer called acute myeloid leukemia, with chemicals at Samsung’s Giheung factory south of Seoul. Yu’s death raises concerns about the working conditions of workers in Samsung factories in particular and the Korean semiconductor industry in general. Her father has spent seven years fighting against Samsung, refusing to take money to silence his daughter’s death to shed light on the use of carcinogens in the Electronic equipment factory, especially semiconductor equipment factory. (Baomoi, 2016)

Figure 9:Number of Samsung Electronics employees worldwide from 2009 to 2017 (in 1,000s) (Source: Samsung)

Figure 10: Safety corrective action request system to create HSE issues database(Source: Samsungengineering.com,2018)

Figure 11: Samsung’s 10 safety rules (Source: Samsungengineering.com,2018)

Figure 12: Samsung safety training (Source: Samsungengineering.com,2018)

Figure 13: Financial summary by division (Source: Samsung Electronics 2015 Business Report )

Figure 14: HSE Sustainability policy (Source: Samsungengineering.com,2018)

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Cancer"

Cancer is a disease in which cells grow or reproduce abnormally or uncontrollably. Cancerous cells have the potential to spread to other areas of the body in a process called metastasis.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: