Environmental Management System for Hydraulic Fracking

Info: 8504 words (34 pages) Dissertation

Published: 16th Feb 2022

Tagged: Environmental StudiesTechnology

Abstract

Over the last few years, there has been an increase in activities regarding hydraulic fracturing, which has raised a lot of questions and controversy around the topic of hydraulic fracturing and whether it has any impact on the environment. Different agencies conducted environmental assessment on how Hydraulic Fracturing could affect water, air quality, marine life, wildlife, etc.

Our team was assigned to develop an environmental management system for our oil company to manage & reduce the effect of Hydraulic Fracturing operation by following international and local standards of ISO 14001.

Contents

Click to expand Contents

1. Introduction

History

2. Literature Review

What is hydraulic fracturing?

Some geological facts behind the use of Hydraulic Fracturing:

What is the hydraulic fracture fluid consisting of?

Chemicals most commonly used in hydraulic fracturing:

Why is Hydraulic Fracturing Used in the United States of America?

Most Common problems associated with the process of Hydraulic fracturing.

A. Surface and underground water contamination.

B. Air Pollution.

Kuwait Clean Fracturing Company’s environmental policy

3. Policy:

4. Planning

4.1 Environmental aspects

4.2 Laws and regulations:

4.3 Objectives and targets:

4.4 Environmental management program (Department):

5. Implementation and Operation

5.1 Structure and responsibility

5.2 Training, awareness and competence

A-Baseline training;

B- Specific training:

5.3 Communication

5.4 EMS documentation

5.5 Document control

5.6 Operational control

5.7 Emergency preparedness and response

6. Checking and Corrective Actions

6.1 Monitoring and Measurement

6.2 Evaluation of Compliance

6.3 Non- conformance and corrective and preventive action

6.4 Control of Records

6.5 EMS Internal Audit

7. Management Review

8. Conclusion

9. References

Table of Figures

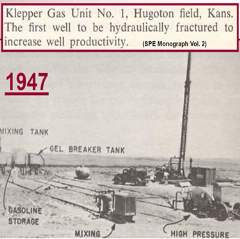

Figure 1 History

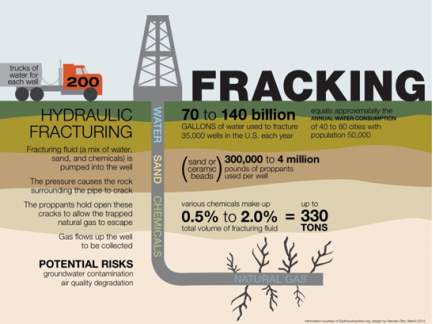

Figure 2 Fracking

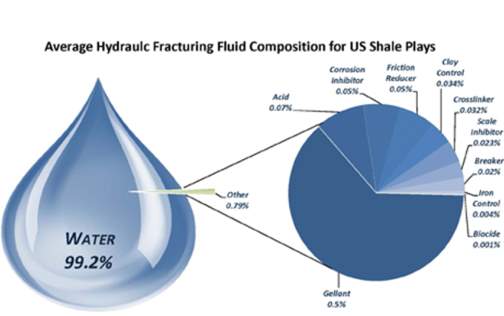

Figure 3 Fluid composition

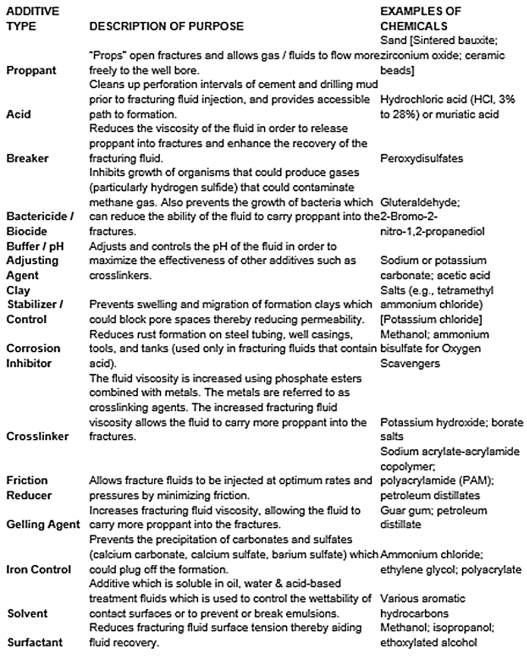

Figure 4 Fracking Fluid

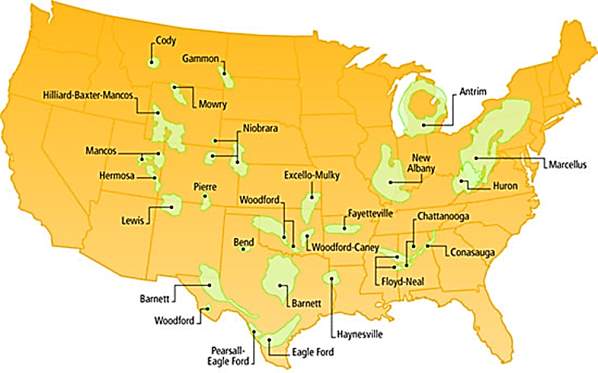

Figure 5 Shale Formation in the US

Figure 7 Methane Emissions in US

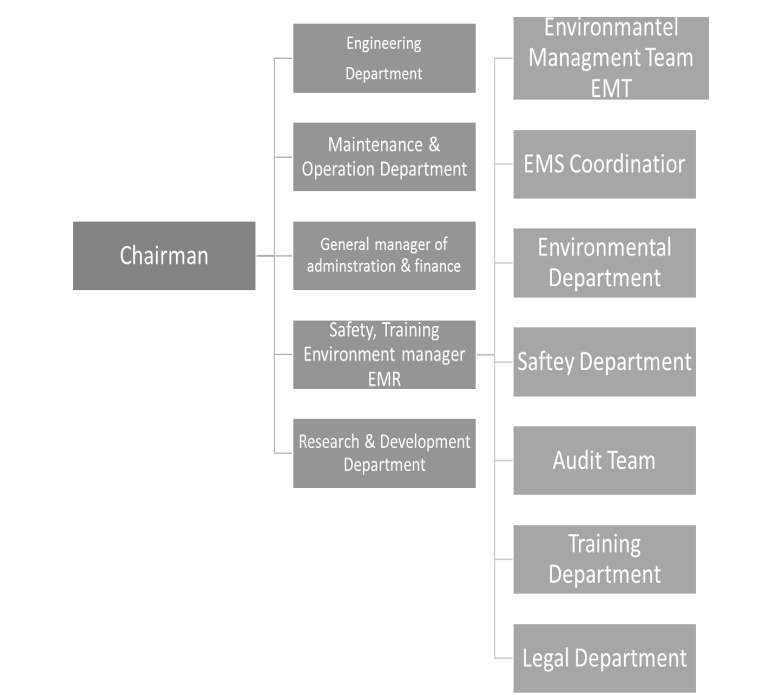

Figure 2 KCFC structure

List of Tables

Table 1 characteristics of chemical that are added to the fracture fluid

Table 2 Identification of environmental aspects

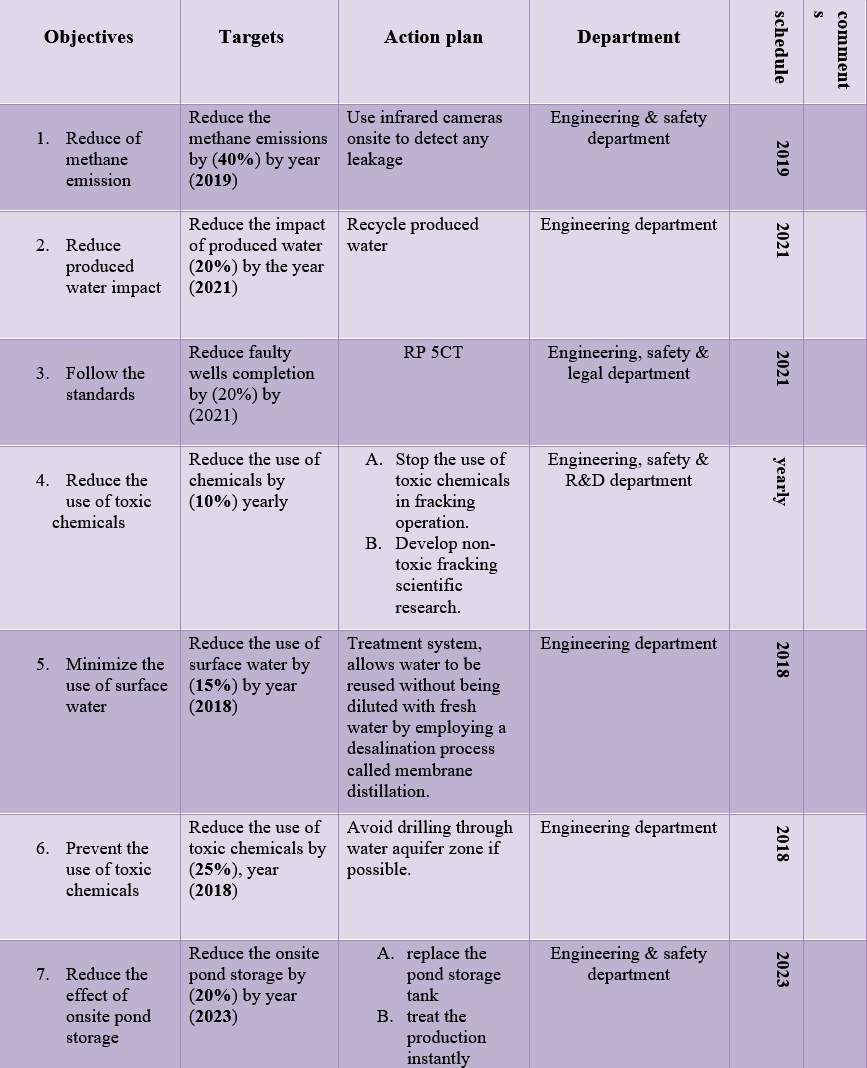

Table 3 list of objectives and targets

Table 4 environmental management program

Table 5 type of communication

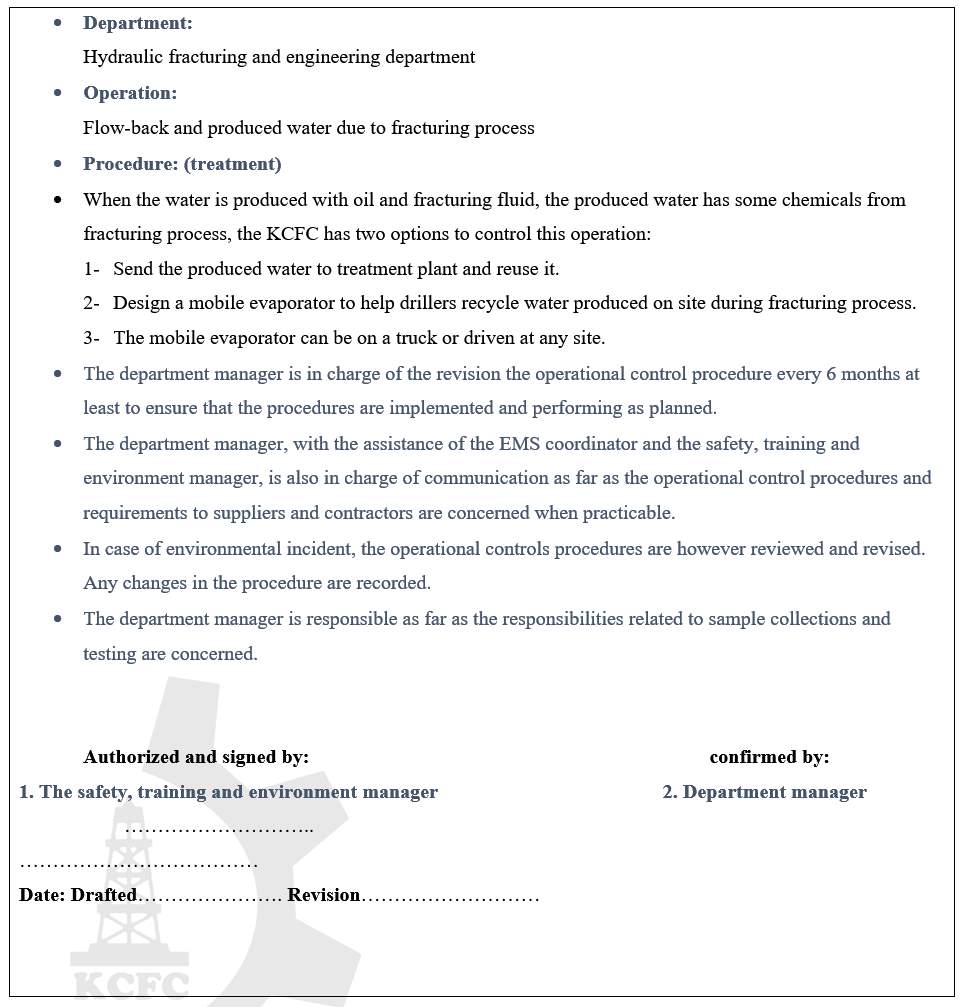

Table 6 operational controls procedure for flow-back and produce water for KCFC

Table 7 Activities & indicators

1. Introduction

History

The birth of modern day hydraulic fracturing began in the 1940s. Where in 1947, Floyd Farris of Stanolind Oil and Gas began a study on the relationship between oil and gas production output, and the amount of pressurized treatment being used on each well. This study lead to the first experiment of hydraulic fracturing, which occurred at the Hugoton gas field, located in Grant County, Kansas in 1947. This experiment did not achieve a great success to produce a significant production increase, however it was marked as the beginning of hydraulic fracturing.

Over 1 million wells in the U.S. have been subjected to hydraulic fracturing, most of them conventional vertical oil and gas wells. Hydraulic fracturing became more important in the 1990s, when improved technology allowed its application to horizontal wells in developing tight gas and oil reservoirs, particularly for shales. (Manfreda, 2015)

2. Literature Review

2.1. What is hydraulic fracturing?

Hydraulic fracturing is a technique used to enhance and stimulate production of oil and gas after a well has been drilled. It consists of injecting a mixture of water, sand (proppant), and chemical additives through a well drilled into an oil- or gas-bearing rock formation, under high controlled pressure. The process is designed to create small cracks (fractures) within the formation, and propagate those fractures to a desired distance from the well bore by controlling the rate, pressure, and timing of fluid injection which eventually facilitating greater access to gas in certain shale formations.

Thus, this method is used to simulate the flow of hydrocarbons in tight or low permeable rock formations increasing the recovery factor rates. (The Geological Society of America (GSA), n.d.)

Figure 2 Fracking

2.2. Some geological facts behind the use of Hydraulic Fracturing:

In some rock formations hydrocarbons are trapped within microscopic pore spaces in the rock. This is especially true in fine-grained rocks, such as shale’s, that have very small and poorly connected pore spaces not conducive to the free flow of liquid or gas. Natural gas that occurs in the pore spaces of shale is called shale gas. These hydrocarbons are very hard to be extracted due to the low permeability. Thus; hydraulic fracturing came as a solution to this problem by creating fractures to enhance the permeability of low permeability rocks such as shale to a point where oil and gas can be economically extracted. (The Geological Society of America (GSA), n.d.)

2.3. What is the hydraulic fracture fluid consisting of?

Water and sand make up 98 to 99.5 percent of the fluid used in hydraulic fracturing. In addition, chemical additives are used such as proppants, biocides, surfactants, viscosity modifiers, and emulsifiers. The exact formulation varies depending on the drilling well type.

Figure 3 Fluid composition

2.4. Chemicals most commonly used in hydraulic fracturing:

Chemicals used in this in fracturing serve many functions such as limiting the growth of bacteria to preventing corrosion of the well casing.

According to Pennsylvania Department of Environmental Protection “The number of chemical additives used in a typical fracture treatment depends on the conditions of the specific well that is being fractured. A typical fracture treatment will apply very low concentrations of between 3 and 12 additives, depending on the characteristics of the water and the shale formation being fractured. Each component serves a specific purpose. For example, the predominant fluids currently being used for fracture treatments in the gas shale plays are water‐based fracturing fluids mixed with friction‐reducing additives (called slick water). The addition of friction reducers allows fracturing fluids and sand, or other solid materials called proppants, to be pumped to the target zone at a higher rate and reduced pressure rather than using only water. In addition to friction reducers, other additives include: biocides to prevent microorganism growth and to reduce biofouling of the fractures; oxygen scavengers and other stabilizers to prevent corrosion of metal pipes; and acids that are used to remove drilling mud damages within the near‐wellbore area.”

Fluids are used to create the fractures in the formation and to carry a propping agent (typically silica sand) which is deposited in the induced fractures to keep them from closing up. (Pennsylvania Department of Environmental Protection, 2010)

Figure 4 Fracking Fluid

Some additives used in hydraulic fracturing:

(Earthworks organization , n.d.)

Table 1 characteristics of chemical that are added to the fracture fluid

2.5. Why is Hydraulic Fracturing Used in the United States of America?

According to Oil and gas experts 60 to 80 percent of all wells drilled in the United States in the next ten years will require hydraulic fracturing to resume producing. In addition; fracturing allows for extended production in mature oil and natural gas reservoirs. Moreover; it makes it possible for the recovery of oil and natural gas from formations that geologists once believed were impossible to produce, such as tight shale formations in the areas shown on the figure below.

(Pennsylvania Department of Environmental Protection, 2010)

Figure 5 Shale Formation in the US

2.6. Most Common problems associated with the process of Hydraulic fracturing.

A. Surface and underground water contamination.

1. Chemicals contamination:

One of the most highly controversial effect of hydraulic fracturing is water contamination and its potential to consequences on human health. The amount of water used in hydraulic fracturing can be as much as 100 times of the water used in conventional drilling. Between 25 and 100 percent of the fluid which is used in drilling procedure may return to the surface; and these produced fluid may contain fracturing chemicals, salt, minerals, heavy metals and naturally occurring radioactive materials from the subsurface, additionally this water must be treated or disposed in safe manners (Henry, Edward, & DeGette).

Chemicals and proppants used during the process that is added to the water which is used in hydraulic fracturing process have raised a lot of environmental and public health concerns which is related to the surface and subsurface water contamination (T. Myers NGWA.org).

Additive used with variety of properties as mentioned previously on the report vary in their toxicity levels. Some of them are known to be safe however other known to be toxic to human like silica, lead, ethanol and isotopes. On top of that manufacturer can have their own secret ingredient which can be remain secret under trade mark protections, without this information it is difficult to tell the potential health hazards (Henry, Edward, & DeGette)

2. Methane contamination:

The potential contamination from methane by seeping into drinking water supplies has received a lot of media attention. According to a study published by PNAS which states that “drinking water within one-kilometer radius of a drilling site have methane concentration of 17 times higher than outside of the one-kilometer radius” figure 7 shows the methane emission sources in the united states which 30% of is emitted by the oil and gas industry (Stephen G. Osborna, Avner Vengosh, Nathaniel R. Warne, and Robert B. Jackson, 2011).

Figure 7 Methane Emissions in US

According to the EPA Methane is the second most emitted greenhouse gas in the United States. The majority of the gas comes from oil and gas activities. Analysts estimate that the energy sector is responsible for about 30% of global methane emissions, with North America leading the charge.

B. Air Pollution

Using natural gas instead of coal can result in reducing air pollution. Where on the other hand combustion that is associated with the extraction process and emissions may cause air quality and health related problems during the hydraulic fracturing process. According to study that have been done in Colorado where the researchers found out that methane was being leaked near hydraulic fracturing operation was emitting twice as much the methane level that should be in the atmosphere, additionally the study have found out that there is a risk on the residents living near these drilling location from the emission than those who live farther away (TEDX, The Endocrine Disruption Exchange, Paonia, CO, USA, 2012).

Since Kuwait Clean Fracturing Company (KCFC) will be engaged in extracting hydrocarbons using hydraulic fracturing which is a technique used to enhance the gas production from unconventional wells, it would be highly possible that this operation would be associated with some environmental impacts and risks. In addition; ever since our top management showed its willingness to become pioneer in the field of producing clean energy and highly concerned with preventing or mitigating these risks to the minimum limit, it will develop and apply an Environmental Management System (EMS) which will create a systematic framework to manage and overcome these environmental risks associated with its operations without affecting its ambition to use the latest technologies possible to achieve the maximum profits.

Before discussing how KCFC did develop its EMS strategy in compliance with ISO 14001 standard, this section will provide a brief overview over EMS, ISO 14001 standard, framework, and components.

What is an Environmental Management System?

According to the Australian department of environment EMS can be defined as “A structured system or management tool by which once implemented it helps the organization to identify the environmental impacts resulting from its activities and to improve its environmental performance. The system aims to provide a methodical approach to planning, implementing and reviewing an organization’s environmental management.” (Department of Environment, water, heritage and arts)

However, to specify the requirements of EMS, the International Organization for Standardization (ISO) developed an international standard ISO 14001 which is considered as the guideline of how to construct an EMS which was favored by our company.

The main operational components according to ISO 14001 standard to build up an effective EMS can be summarized as follows:

- Create an environmental policy which will show the company’s desire and commitment to minimize the impact of its activities on the environment.

- Plan which include:

- Environmental aspects

- Legal and other requirements

- Objectives, targets, and programs

- Do which include:

- Responsibilities

- Competence, training, and awareness

- Communication

- Documentation

- Control of documents

- Operational control

- Emergency preparedness and response

- Check which include:

- Monitor and measure

- Evaluate compliance

- Nonconformity, corrective and preventive action

- Control of records

- Internal audits

- Act which include:

- Management review

- ISO 14001 audit

By fulfilling these ISO 14001 EMS components the company will ensure a continuous improvement of its environmental performance, reduce operating costs, maintain compliance, and increase employee’s involvement.

In the next section, KCFC Development Strategy of EMS in compliance with ISO 14001 standard will be discussed in detail.

3. Kuwait Clean Fracturing Company’s environmental policy

KCFC is committed to leading the Oil and Gas industry in the State of Kuwait for hydraulic fracturing by minimizing the impact of our activities on the environment.

The key points of our strategy to achieve this are:

- Measure our operations activities impacts on the environment and set targets for ongoing improvement.

- Ensure the safe management of wastewater by evaluating our operations to ensure they are as efficient as possible and providing safe and legal options for disposal of flow back and produced water.

- Minimize any greenhouse emissions through using better technologies and practices.

- Refrain from using toxic chemicals associated to the fracturing process and use environment friendly alternative chemicals.

- Implement a training program for our staff to raise awareness of environmental issues and enlist their support in improving the KCFC performance.

- Meet all the environmental legislation that relates to our company and strive to follow best practices.

- Apply health safety and environment program followed by K companies.

- Use of best available technologies to protect the environment as much as possible.

- Communicate our environmental policy to the public to promote their support.

- Use an accredited program to offset the greenhouse gas emissions generated by our activities.

- Seek continuous advancement by monitoring our progress and remaining proactive.

Signed by company’s director Mr. Fahad al-Qattan

4. Planning

Planning is an identification of environmental aspects and their level of impact on the environment, followed by the legal requirements that should be followed. Moreover; this subsection will discuss the chain of objectives and targets of our company. Eventually, environmental management programming, which has to meet the goals of our environmental policy as well as the legal and other requirements.

4.1 Environmental aspects

KCFC has assembled its environmental aspects and impacts (shown in table below) with the intention to set its own significant aspects. Our company has established its own significant aspects based on a rating system where the value 0 means that there is no impact and the value 5 means that there is a significant impact. An aspect with a total score of 18 or 19 is considered as a significant aspect.

Table 2 Identification of environmental aspects (Modified after Biltayib)

| Activities | Environmental Aspects |

impact on air |

impact on water quality |

impact on human health |

impact on wildlife |

impact on natural resources |

impact on marine life |

impact on water quantity |

impact on local infrastructures |

impact on economy |

impact on soil |

total environmental score |

|

hydraulic fracturing |

Venting of methane | 5 | 3 | 5 | 5 | 2 | 1 | 0 | 0 | 3 | 0 | 24 |

| Flow back and produced water | 4 | 5 | 4 | 3 | 0 | 0 | 0 | 0 | 3 | 2 | 23 | |

| Faulty well construction | 0 | 5 | 5 | 2 | 4 | 0 | 0 | 0 | 4 | 3 | 23 | |

| Use of toxic chemicals | 1 | 5 | 5 | 3 | 0 | 0 | 0 | 0 | 4 | 3 | 21 | |

| Use of surface water | 0 | 0 | 0 | 3 | 3 | 3 | 5 | 2 | 2 | 1 | 19 | |

| Contamination of ground water | 0 | 5 | 5 | 1 | 4 | 0 | 0 | 0 | 4 | 0 | 19 | |

| On site pond storage | 4 | 1 | 4 | 4 | 0 | 0 | 0 | 0 | 3 | 3 | 19 | |

| Pipe leakage | 2 | 2 | 4 | 4 | 1 | 0 | 0 | 0 | 3 | 1 | 17 | |

| Transportation | 3 | 1 | 2 | 1 | 0 | 0 | 0 | 4 | 3 | 1 | 15 | |

| Chemical mixing | 1 | 0 | 4 | 3 | 1 | 0 | 3 | 0 | 2 | 0 | 12 | |

| Power generators | 4 | 0 | 3 | 2 | 0 | 0 | 0 | 0 | 3 | 0 | 12 | |

| Silica sand inhalation without protection | 0 | 0 | 5 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 9 | |

| Noise | 0 | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 7 | |

| Seismic activity | 0 | 0 | 3 | 2 | 0 | 0 | 0 | 0 | 1 | 0 | 6 | |

| Water waste disposal | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 2 | 1 | 0 | 6 | |

| Spills from trucks or tanks while transportation | 0 | 0 | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 2 | 5 |

4.2 Laws and regulations

The laws and regulations which KCFC follows are obtained locally from Kuwait (EPA) laws, as well as international laws and regulations. These laws and regulations will serve the company’s activities and services that will protect the environment.

List of laws regarding the aspects:

- Kuwait laws under (EPA)

- (Article 52): this article focuses on gas emissions.

- (Article 96): this article takes underground and surface water.

- (Article 50): this law is about the air quality.

- (Article 21 and 23): both talks about chemical substances management and toxic chemicals.

- International laws:

- (Clean air act): law on air quality.

- (Clean water act): law on water quality.

4.3 Objectives and targets

KCFC have set their own objectives and targets in the table below, based on the significant aspects selected from the identification of environmental aspects table.

Table 3 list of objectives and targets (Modified after Biltayib)

|

significant aspect |

Objectives |

Targets |

|

Reduce of methane emissions | Reduce the methane emissions by (40%) by year (2019) |

|

Reduce produced water impact | Reduce the impact of produced water (20%) by the year (2021) |

|

Follow the standards | Reduce faulty well completion by (20%) by the year (2021) |

|

|

Reduce the use of toxic chemicals | Reduce the use of toxic chemicals by (10%) yearly |

|

Minimize the use of surface water | Reduce the use of surface water by (15%) by year (2018) |

|

Prevent the use of toxic chemicals | Reduce the use of toxic chemicals by (25%), year (2018) |

|

Reduce the effect of onsite pond storage | Reduce the onsite pond storage by (20%) by year (2023) |

4.4 Environmental Management Program (Department)

KCFC has established its EMS Program based on the objectives and targets set in the table above. Our company aims to define its action plans and choose the appropriate department for it using the table below.

Table 4 Environmental Management Program (Modified after Biltayib)

5. Implementation and Operation

The implementation and operation section requires the company to define the roles, responsibilities and authorities of all employees, commitment to staff training, maintain an effective of communication channels, effective approval of document and operational controls, and maintain necessary awareness on emergency preparedness among the staff.

5.1 Structure and responsibility

Top management of KCFC will commit to providing resources including (human resources and specific skills, company structure, technological and financial resources) which are essential to the implementation and control of the EMS. Top management will be defined, allocates the roles, responsibilities and authorities of all employees of our company in order to facilitate effective EMS. KCFC’s management structure has a chairman and 5 general managers including; engineering, maintenance, administration, research and development, and the safety training environment manager which is the environmental management representative (EMR). For an EMS to be effective EMR was included to the management structure to achieve our environmental objectives and targets set by the company. EMR plays an essential role in order to control or develop an EMS ISO 14001 standard. EMR manger has 7 sections including EMT, EMS coordinator, environmental department, safety department, audit team, training department and finally the legal department.

Individuals, teams, and departments that have significant role in the EMS ISO 14001 and their responsibilities:

- Chairman: Responsible for approving and signing the company’s policy and leading all the division’s managers within the company.

- Chief Operating Officer (COO): The senior manager for all operations of the company and in-charge of providing resources for development.

- Engineering department: Responsible for construction and supplying all operations.

- Maintenance Manager: Responsible for waste management.

- General Manager of administration & finance: Responsible for funding and management.

- Director of Quality: Is the EMR and responsible for the implementation and maintenance of EMS, and reporting on the performance of EMS to top management.

- Research and development department: Responsible for research and development.

- Environmental Management Team (EMT): Members of the activity who are responsible for representing their area or department in different sides of EMS.

- EMS coordinator: Responsible for identifying, assigning, scheduling, providing the necessary support for, and ensuring completion of all tasks relating to the EMS.

- Environmental Department: responsible for the environmental issues or problems.

- Safety Department: Responsible for health and safety

- Audit Team: Team assists in setting the general objectives towards good governance on the environment and check to make sure these objectives are met or even improved.

- Training Department: Responsible for training all employees.

- Legal Department: Responsible for following the laws and regulations in local and international.

- The figure on the next page illustrates the structure of KCFC, for the implementation and operation in accordance with ISO 14001 Standard.

Figure 2 KCFC structure

Table 4 gives a summary of the responsibilities and the level of involvements to make the EMS effective in KCFC.

Table 5 Responsibilities and Level of involvement in the activities

| Tasks | Chairman | EMT | Audit Team | General managers | Safety, Training environmental Manager (EMR) |

| Developing an environmental policy | Approval | Involved | Involved | Involved | Responsible |

| Conducting legal and other requirements | Involved | Involved | Involved | Responsible | |

| Conducting and analysis of environmental aspects | Involved | Deeply Involved | Responsible | ||

| Setting objectives and targets | Involved | Involved | Responsible | ||

| Conducting training | Involved | Involved | Responsible | ||

| Internal & external Communication | Involved | Involved | Involved | Responsible | |

| Documentation system and control | Involved | Involved | Responsible | ||

| Measurement and Evaluation | Involved | Involved | Responsible | ||

| Coordinating emergency response efforts | Involved | Involved | Responsible | ||

| Conducting Audits | Involved | Deeply Involved | Responsible | ||

| Maintenance of equipment/tools to control environmental impact | Involved | Involved | Responsible | ||

| Conformance facility’s EMS requirements | Involved | Involved | Involved | Responsible | |

| Maintenance of EMS records | Involved | Involved | Responsible |

5.2 Training, awareness and competence

According to KCFC’s environmental policy statement, all employees are responsible to follow, support, and enforce the company’s environmental scope in all divisions of the company. KCFC will implement and maintain procedures to identify the training needs associated with its environmental aspects and its EMS, and develop program(s) to ensure awareness and competence of all KCFC’s employees.

A - Baseline training

KCFC ensures that its entire staff and especially those that might have the potential to cause significant impact on environment are identified by the company, qualified and competent on the basis of education, drawing, and experience.

KCFC identified the training needs and requirement relevant to our aspects and EMS. KCFC staff and employees were trained to be aware of:

- Commitment to the KCFC’s environmental policy and requirements of EMS.

- Our KCFC’s activities environmental aspects and related impact.

- Their role or responsibilities to make our EMS successful.

- Laws and regulation on hydraulic fracturing.

B - Specific training

KCFC requires identifying training needs and providing specific training to those who work and could cause an environmental impact. It will provide specific training for employees whose activity result in flow-back and produced water. In this case, only production engineers and chemists will be involved.

Areas to be considered will be:

- KCFC’s policy statement towards environmental commitment.

- Specific objectives and targets towards flow-back and produce water.

- Local and international laws and regulation in produced water.

Training areas to be considered for KCFC environmental training:

- New emerging surface treatment technologies.

- Managing produced water.

- Composition and characteristics of produced water.

- Environmental risk assessment and monitoring.

- Options available for produced water treatment.

5.2 Communication

A - Internal Communication

KCFC’s internal communications include employee’s meetings, notice boards, and the company’s internet. The EMR will provide information regarding the EMS (such as the policy, objectives, targets and program(s).

B - External Communication

As per the policy, KCFC will communicate its environmental policy to the public to promote their support. All internal and external communications will be discussed and reviewed during the meetings and the decisions will be recorded in meeting minutes.

The EMS coordinator of KCFC will discuss and decide whether to communicate externally about its significant environmental aspects, the decision will be documented in the meeting minutes. The EMS committee will establish and implement a method for this external communication if needed be.

The EMS coordinator is responsible for identifying communication methods. Table 5 below gives an example of what’s included in both external and internal communication.

Table 5 type of communication

| Internal communication | External communication |

| Posted notices | Company internet web site |

| E-mail or internal | |

| telephone, meetings | Letters receive |

5.4 EMS documentation

KCFC will establish and maintain information either in paper or electronic form to describe the core elements of the management system and their interactions and also to provide direction to related documentations, such as KCFC ‘s policies, procedures, and records.

KCFC is following the standard documentation that required by ISO 14001 in order to ensure that the EMS is well understood and operation as designed. EMS documentation will provide a direction for KCFC’s employees on the application of the EMS. There may also external parties that interested in how KCFC’s EMS is designed and implemented such as customers, regulators and the public. KCFC’s procedure can be useful for establishing EMS documentation.

KCFC’s EMS documentation includes the following:

- Environmental policy, and objectives and targets.

- Scope of EMS, which is to develop an environmental management system of our company to reduce the effect of hydraulic fracturing operation.

- Documents including records required by ISO 14001.

- Document including records determined by KCFC’s top management, to ensure the effective planning, operation control to all activities that has a significant impact to the environment.

5.5 Document control

KCFC’s EMS documentation ensures that everyone is working with the appropriate EMS documents. KCFC has a procedure for describing how the documents should be controlled, when employees can easily locate working documents that are periodically reviewed, KCFC can be guaranteed that employees are working with the right information.

KCFC’s structure includes five departments; each department will be supplied with specific document related to department’s objectives and targets within the EMS to allow easy access to the staff members in each department. After every revision of the EMS, all documents will be updated and outdated ones withdrawn from points of usage. Moreover, the EMR of the company will have copies of all documents related to the EMS for backups and for training purposes.

Document control required by the ISO 14001, the KCFC implemented a procedure to:

- Approve document prior issuance.

- Review, update, and document.

- Ensure that the documents remain legible.

5.6 Operational control

KCFC’s EMT follows a process to identify aspects that may lead to significant impacts and uses these to establish objectives and targets, which are addressed in the KCFC’s environmental management program(s). Operational controls ensure that activities associated with significant environmental aspects are in line with the environmental policy and progress toward fulfilling its objectives and targets.

KCFC has operational controls for the environmental aspects associated with some of their activities, which includes venting of methane, produced water, well completion, toxic chemicals, and on site pond storage. By following the ISO 14001 standards, KCFC improves a specific documented instruction to cover all the significant environmental aspects and periodically reviewing these set of instruction. KCFC set the procedure to develop effective operational controls for significant impacts. Flow-back and produced water has been used as an example to prove how this procedure can be applied.

Table 6 operational controls procedure for flow-back and produce water for KCFC

5.7 Emergency preparedness and response

KCFC will implement and maintain a procedure to identify potential emergency situations and responses to such situations in order to prevent or mitigate environmental impacts that may associate with them. In order to develop emergencies preparedness and response plans, the KCFC implemented procedures to be undertaken in cases of emergencies as followed:

- The company will provide copies of the KCFC’s emergency preparedness and response plans and procedures, to train workers on how to respond, including their roles and level of response to potential chemical spills or leaks when they are involved with the site.

- KCFC will provide contacts for the company’s on-site emergency coordinator (or at least critical contact names and phone numbers) in case of emergency.

- KCFC will develop and implement procedures to safely check chemical in produced water in order to reuse or disposal.

- KCFC will communicate to workers that flammable gases might be present as the formations are fractured.

- KCFC will develop and implement an effective operating plan and procedure, which include information about the equipment, operating limits, startup and shutdown procedures, normal operations and emergency procedures.

- KCFC will Implement procedures to the workers in flow back operations to be aware of potential hazards. Fluid and materials flowing back at very high pressures from the well may contain debris such as rocks and mud, plugs and other parts, methane gas, hydrogen sulfide, oil, water, sand, and small amounts of chemicals.

KCFC will review and revise its emergency preparedness and response procedure for at least 1 or 2 years or as a result of change, in particular after the occurrence of accidents or emergency situations. KCFC will periodically test the procedure and the preparedness where practicable.

6. Checking and Corrective Actions

KCFC seeks to measure the performance of its objectives and targets, its implemented operations as well as its compliance with the regulations and laws it follows. KCFC will make sure that the EMS accommodates with ISO 14001 standard. If there is any unconformity, KCFC will handle it and make the necessary corrective actions.

6.1 Monitoring and Measurement

Our company has implemented a procedure to frequently monitor and measure the impacts of our operations on the environment. Moreover, our Ems team has reviewed the environmental aspects and specified the monitoring requirements on:

- Aspects

- Operation control

- Monitoring and measurement

Further monitoring will be performed to monitor the objectives and targets and have it documented. KCFC will establish performance indicators to monitor performance of the objectives and targets. The table below shows the indicators with their related activities that KCFC have set.

Table 7 Activities & indicators

| Activities | Indicators |

| Regulations and Laws | # of occasions of unconformity |

| Safety & Training Procedures | # of people that completed the procedure |

| Identification of Aspects, Objectives & Targets | # of significant aspects, objectives and targets identified |

| Corrective and Preventive Actions | Time required to perform corrective and preventive actions |

| Methane emissions | Occurrence of methane emission |

| Social | # of complaints from people towards the company |

| Employees Involvement | # of obstacles/problems affecting the idea generation of employees and their involvement |

6.2 Evaluation of Compliance

- KCFC will periodically evaluate the compliance with the applicable legal requirements.

- KCFC will review its operations every 4 years to determine if it complies with the legal requirements set by the company.

- KCFC will evaluate compliance with legal requirement through an internal audit process and safety inspection.

6.3 Non-conformance and corrective and preventive action

KCFC will implement and maintain procedures that deals with non-conformities to and take the necessary corrective actions and preventive actions if needed.

KCFC procedure defines the requirements for:

- Identifying any non-conformities that occurs.

- Determining the causes of the occurrence of any non-conformities.

- Taking actions, either corrective or preventive actions, depending on the type of non-conformity being faced.

- Recording non-conformities, their causes and actions taken against them by the company.

- Review the effectiveness of the actions taken by the company.

6.4 Control of Records

KCFC have established, implemented, and maintained records to ensure that there is a conformity with the requirements of the EMS and the standard ISO 14001.

KCFC records contains non-conformance, preventive and corrective actions, training records, incident reports, complaints, responses, maintenance records.

6.5 EMS Internal Audit

KCFC will conduct internal audits to its own EMS to determine if the EMS:

- Implemented and maintained properly.

- Conforms to planned arrangements.

KCFC will schedule Internal audits based on the activities and results and their importance. Internal audits will be implemented annually to make sure that the internal audit system is functioning properly.

7. Management Review

KCFC will conduct a management review semiannually, and if it’s required to do more, it will be held quarter annually.

Attendees of these meetings will be all the departments managers and the head of the meeting will be the EMS coordinator, the EMS coordinator will evaluate Management Performance Review Form (appendix A). moreover; all the necessary inputs for the meeting will be prepared by the coordinator.

Inputs of the meeting will include:

- Performance of the EMS.

- Objectives and Targets progress.

- Statutes of Corrective and preventives actions.

- Review internal and external audits.

- Recommendations for future improvements.

Outputs of the meetings:

- Possible changes for the EMS policy.

- Possible changes for the objectives & targets.

- Possible changes for any EMS elements that can ensure continual improvements.

8. Conclusion

In conclusion, hydraulic fracturing opened a new horizon in oil and gas industry especially with the escalating demand of petroleum crudes due to the booming population and industrial expansion all over the world. This innovative operation helped exploiting and enhancing the petroleum production from unconventional wells which improved the economy of so many countries by increasing the supply of hydrocarbons to fulfill the market needs and create a new job opportunities which eventually led to prosperity.

However, we should take into consideration the possible environmental impacts or damages that might be caused due to this operation on health and environment if this operation is not conducted efficiently and in line with international standards to preserve the environment and achieve sustainability.

Therefore; our company decided to utilize the best technologies related to extracting of oil and gas from unconventional wells by hydraulic fracturing in accordance with having an explicit commitment and procedures to persistent environmental management improvement. Moreover; setting an EMS strategy for our company will provide us with the framework which will assure that our environmental performance is well managed, controlled, and updated in regular basis.

9. References

Earthworks organization . (n.d.). Hydraulic Fracturing 101. Retrieved from earthworksaction.org: https://www.earthworksaction.org/issues/detail/hydraulic_fracturing_101#.V6nHOJh96iN

Manfreda, J. (2015, apr 13). Retrieved from http://oilprice.com/: http://oilprice.com/Energy/Crude-Oil/The-Real-History-Of-Fracking.html

Pennsylvania Department of Environmental Protection. (2010, july 20). Hydraulic Fracturing: The Process. Retrieved from fracfocus: https://fracfocus.org/hydraulic-fracturing-how-it-works/hydraulic-fracturing-process

Stephen G. Osborna, Avner Vengosh, Nathaniel R. Warne, and Robert B. Jackson. (2011, April 14). Methane contamination of drinking water accompanying gas-well drilling and hydraulic fracturing. PNAS. Retrieved 8 7, 2016, from http://www.pnas.org/content/108/20/8172.full.pdf

The Geological Society of America (GSA). (n.d.). GSA Critical Issue: Hydraulic Fracturing. Retrieved 8 5, 2016, from http://www.geosociety.org/: http://www.geosociety.org/criticalissues/hydraulicFracturing/defined.asp

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Technology"

Technology can be described as the use of scientific and advanced knowledge to meet the requirements of humans. Technology is continuously developing, and is used in almost all aspects of life.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: