Environmental Management System (EMS) for Oil Company

Info: 8741 words (35 pages) Dissertation

Published: 9th Dec 2019

Introduction

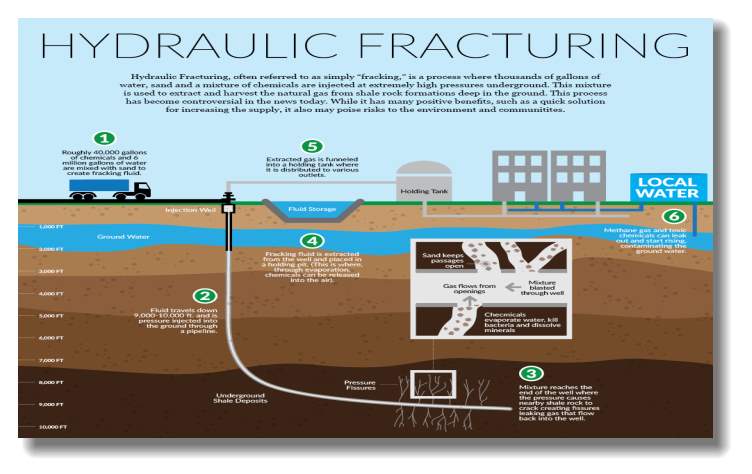

With the highly demand on oil and gas as a source of energy, operators are anxious to find petroleum resources even if it requires drilling a challenging wells, such as drilling to reach shale formations by using hydraulic fracturing process. The process of hydraulic fracturing gives great quantity of hydrocarbons but it involve many potential impacts on the environment. in order to reduce and avoid the risks and impacts of hydraulic fracturing on the environment, developing EMS plan would be crucial. Environmental Management System (EMS) is defined as a series of processes and practices that support an organization to decrease its environmental impacts and increase its operating efficiency. An EMS system depends on several stages that need to be followed.

(EMS)

Objective of this research

In this report the reader is expected to understand the EMS system and how we can build a whole new system for Kuwait oil companies focusing on the reduction of the effect of hydraulic fracturing process. this research covers the hydraulic activity and it is environmental impact and it is subdivided into three major areas :

- The first section gives a general idea of the hydraulic fracturing process for exploiting and production of oil and gas and the associated environmental impacts.

- The second section covers the use of ISO 14001 plan to minimize and reduce the effect of hydraulic fracturing on the environment.

Chapter 2

Literature Review

History of Hydraulic Fracture

Hydraulic fracturing began as an experiment in 1947, and the first commercially successful application followed in 1950. As of 2012, 2.5 million “frac jobs” had been performed worldwide on oil and gas wells; over one million of those within the U.S. Such treatment is generally necessary to achieve adequate flow rates in shale gas, tight gas, tight oil, and coal seam gas wells. Some hydraulic fractures can form naturally in certain veins or dikes.

The development of science & technology has led to discover a new technique in oil & gas industry called Hydraulic Fracturing. This method is used to stimulate shallow, hard rock oil wells at the beginning of 1860s. However, dynamite or nitroglycerin detonations were used to increase oil and natural gas production from petroleum bearing formations. On 1865, Edward A. L. Roberts received a patent for an “exploding torpedo” where he uses liquid and solidified nitroglycerin that applied to water and gas wells. Stimulation of wells with acid, instead of explosive fluids, was introduced in the 1930s. Due to acid etching, fractures would not close completely resulting in further productivity increase.

“Acid fracturing”. Society of Petroleum Engineers. Retrieved 12 October 2014.

In 1997, Nick Steinsberger, an engineer of Mitchell Energy applied the slickwater fracturing technique, using more water and higher pump pressure than previous fracturing techniques, which was used in East Texas by Union Pacific Resources in the Barnett Shale of north Texas. In 1998, the new technique proved to be successful when the first 90 days gas production from the well-called S.H. Griffin No. 3 exceeded production of any of the company’s previous wells.

Robbins, Kalyani (2013). “Awakening the Slumbering Giant: How Horizontal Drilling Technology Brought the Endangered Species Act to Bear on Hydraulic Fracturing” (PDF). Case Western Reserve Law Review. 63 (4). Archived from the original (PDF) on 2014-03-26. Retrieved 2016-09-18.

Hydraulic Fracture

It also called fracking: describes the recovery of natural gas from deep layers inside the earth, porous rock is fractured by the use of water, sand and chemicals in order to release the enclosed natural gas. In addition, almost 60% of all new oil and gas wells are drilled by using hydraulic fracking. Fluid used contains mainly water, sand, and chemicals.

On average:

- 8 million liters of water

- Several thousand tons of sand

- 200,000 liters of chemicals

Process:

First, a shaft is drilled several hundred meters into the earth. From there, a horizontal hole is drilled into the gas-bearing layer of rock. Next, the fracking fluid pumped into the ground using high-performance pumps. The mixture penetrates into the rock layer and produces innumerable tiny cracks. The sand prevents the cracks from closing again. Next, the majority of the fracking fluid is pumped out again, and now the natural gas can be recovered. As a rule, the fracking fluid is pumped back into deep underground layers and sealed in there.

Environmental Impacts of Hydraulic Fracturing. (2012). Retrieved from Exploration and Exploitation of Unconventional Natural Gas Deposits: https://www.umweltbundesamt.de/sites/default/files/medien/461/publikationen/4346-1.pdf

Hydraulic Fracturing:

Since the discovery of oil in1859 until now it has formed world’s major commercial source of energy. In 1968, Due to the depletion of well sources, geologist went to new discovery to extract oil and gas horizontally by fracking tight shale formation to create a path for hydrocarbons and this was called hydraulic fracturing.

Hydraulic fracturing is a process of oil and natural gas extraction.Where companies drill wells thousands of feet deep into the shale rock formations underground. These wells are cased with steel pipes and then a solution of water, sand and chemicals is pumped into these wells under high pressure. This process creates cracks within the shale to allow oil and natural gas to be released into these wells and pumped to the surface through the wellhead. However, in order to extract these trapped substantial deposits many environmental impacts are associated

http://sites.nicholas.duke.edu/avnervengosh/files/2011/08/Quantity-and-source-of-unconventional-wastewater.pdf

http://blogs.nicholas.duke.edu/thegreengrok/frackingwater/

Chapter 3

Methodology

About the company

The EMSH Company stands for the Hydraulic Management System for Hydraulic Fracturing. The company has built for a specific aim, which is eliminating the side effects and impacts of the hydraulic fracturing processes that is used now days. This company is implemented in Kuwait. This company is build based on the ISO 14000 standards. It is the company duties to conserve our earth from any harmful activities such as the hydraulic fracturing process.

This company was established in 22/1/2017 by partnership of four members. The members are Batool pour shamsi, Kawther AlQattan , Dana Ali and Sara AlQallaf. The decision to build this company has been taken between us. Since we are petroleum engineers so we are focusing on hydraulic fracturing process, it is widely used in extracting oil from different reservoirs.

(Brief introduction to EMS requirements)

1 Environmental policy

Purpose:

The purpose of the environmental policy is to have regulations that will control the impacts of the environmental aspects that are generated from the hydraulic fracturing process, therefore, will improve of the company’s ability to manage and account for environmental problems and hazards.(1)

(1)http://media.metro.net/about_us/sustainability/images/Environmental.pdf

Scope:

Within this scope we are dedicated to follow opportunities to reduce the effects of hydraulic fracturing by making some adjustment to the chemicals that are used and apply healthy techniques to the environment based on the company’s regulations and policy, to avoid waste and to observe with all environmental regulation in order to protect the environment. (2)

https://www.trendcontrols.com/en-GB/About/Documents/EMR_01_Rev_05_Environmental_Scope_and_Policy.pdf

Procedure:

- Reducing the impact on the environment of new techniques by analyzing the aspects of those new improvements before implementation.

- Apply direct methods for the organization plan to achieve its environmental impacts.

- Avoid waste and pollution through operative control procedures.

- Minimizing the pollution at the basis and monitoring the environmental effects by technological prospects.

- Minimize the influence of hydraulic fracturing operations on human, water, soil and atmosphere.

- Pursuing to frequently enhance our environmental performance using the environmental management system to avoid risks.

- Applying our environmental policy and objectives activities on a professional basis and improve feedback effectively.

- Directly connect the environmental aspects to the related requirements from the legislation.

- For determining the significant aspect, the related legislation that is applied to the environmental activity regulates the significant environmental aspect.

2 Environmental aspects

Purpose:

The purpose for this requirement is to identify the related environmental aspects which is associated with the effect of Hydraulic Fracturing on the environment, and identify the most significant aspects and impacts due to their hazardous effect.

Scope:

The related activities and facilities of the significant environmental aspects need to be determined in order to improve the company’s activities.

Definitions:

- Environmental aspect:

Part of any organization or activity that is relate to the environment.

- Environmental impact:

Resulting effects are either good or bad from the aspect.

Procedure:

Identification of environmental aspects and impacts:

First of all in order to identify the environmental aspect few steps should be followed to determine these aspects:

- The major activities of the process need to be examined to put all the effects either small or large in consideration.

- All environmental aspects need to be identified and clear.

- All environmental impacts whether good or bad are determined.

- The environmental aspects will be examine based on a scale (low , moderate , high) due to their effect from the environmental impacts as shown on the figure below.

Hydraulic fracturing as a modern technique has a very good results on enhancing oil production rates, on other hand, its impact on the environment can not be neglected as it effect the whole ecosystem is obvious where this result from the following aspects : Chemicals, proppants, sand, fire gun, flow back water, noise and well logging (gas radiation).

| IMPACT

ASPECT |

HUMAN

HEALTH |

AIR

EMISSION |

EARTHQUAKES | WATER

CONTMINTATION |

CLIMATE

CHANGE |

CORROSION | CONSERVATION OF NATURAL RESOURCES | RANK |

| TOXIC CHEMICALS

SPILLS |

High | high | low | high | high | high | NA | 5 |

| PROPANT,SAND | Moderate | low | low | high | low | NA | NA | 1 |

| FIRE GUN | High | low | low | moderate | NA | NA | NA | 1 |

| FLOW BACK WATER CONTAMINATION | High | low | NA | high | NA | high | NA | 3 |

| NOSIE | High | NA | NA | NA | NA | NA | NA | 1 |

| WELL LOGGING

(GAS RADITAN0) |

High | NA | NA | آNA | NA | NA | NA | 1 |

The table below shows the significance aspects, while the impacts that have the more (high) score is the significant environmental aspect.

As shown in the table the significant environmental aspects for our company are:

- Toxic chemical spills

- Flow back water

| Significant Aspect | Rank |

| Toxic chemicals spills | 5 |

| Flow Back Water | 3 |

Responsibilities:

A development, revision for the significant environmental aspects that are related to the company’s activity should be done by the training and safety manager due to his responsibility, in order to increase the efficiency for the company’s work.

3 legal and other requirements

Purpose

Obtaining and maintaining the legal requirements that are abdicable to the environmental aspects of the company activates/products/services and facilities.

Scope

Describing the procedures for approaching to the legal requirements, which are related to Activities, products and services of the company.

Procedures

- Identifying environment laws and regulations associated with environment aspects by the environmental management team.

- Every department in the company are responsible to distinguish the legal requirements, which are applicable to the significant aspects of each department.

- Maintaining a list of all legal requirements by the environment management team.

- A list of the requirement with a summary should be presented of the manager of each department.

- Reviewing the legal and other requirements.

- The list of the legal requirement are updated in the company’s website.

Reference : biltayeb book

Responsibilities

- Environment manager team

- Manager of each department

- All employees shall respond to the regulations.

Reference : biltayeb book

Legal requirements of EMSH

| code | description |

| Clean air act

[40 CFR parts 50-99] |

Determine surrounded and source emission criterion and statement requirements for hazardous air pollution. |

| Clean water act

[40 CFR parts 100-145,2200-232,410-471] |

Determine surrounded and source effluent criterion and requirements for water pollution including fountain that discharge to the sewer system. |

| Toxic substances control act

[40 CFR parts 700-799] |

Controlling the manufacturing, using, allocation, development and elimination of chemicals. |

| Emergency planning and community right to know act

[40 CFR parts 350-374] |

Determine a program to report the public the toxic chemical and hazardous materials release. |

| Hazardous materials transportation act

[49 CFR parts 100-180] |

Determining standards for having safer transportation of the hazardous materials. |

Reference : www.epa.gov/sites/productio

4 objectives and targets

Purpose

This stage is very important in order to identify the environment objectives and targets based on the significant environmental impacts. The objectives and targets are set In order to reduce the harmful side effects and risks form the significant aspect.

Scope

It is actually setting the environmental management System objectives and targets.

Definitions

Objective is the overall environmental goal, emerging from environment policy that the regulation put to achieve.

Targets are actions that need to perform in order to achieve the objective of the institute.

Reference :

http://www.epd.gov.hk/epd/english/how_help/tools_ems/ems_6.html

http://www.kdheks.gov/environment/download/EMS.pdf

Setting objectives and targets:

- Firstly its need to meet the company’s policy.

- In setting the environment objectives, the consideration of the environment aspects and impacts are important.

- Put in consideration the company’s priority in reducing risk. Seeking first for the most actions that cause risk.

- In setting the objectives, the significant aspects is having the priority.

Reference : biltayeb book

Objectives may include the following:

- Reducing the release of pollutions in the environment

- Controlling the significant aspects

- Reducing the resources depletions

- Awareness for the employees

http://www.tel.com/environment/ehsreport/document/2001/er2001_08.pdf

Procedures in general

- Identifying the significant environment aspects, each significant aspect should have an objective and a target.

- Reviewing all or environmental objectives in order to see if it needs to set more objectives or not.

- The environment policy should be in consideration in setting the objectives and targets.

- Identifying the impact of each objective.

- Setting targets to achieve the company’s objectives.

- All the company’s departments are responsible in the objectives and targets of the company.

- Improvement of the objectives and targets throughout the year.

- Progressing in the objective and targets throughout meetings.

- Removing the objective and targets are possible only by the management review department.

- The final objective and targets of the company listed in the company’s website, these objectives and targets are fixed.

Procedures in case of hydraulic fracturing

- Chemicals additives and the flow backwater are considered as significant aspects.

- Setting objective of each significant aspect.

- Chemicals additives objectives are

- Reduce usage of hazardous chemicals

- Proper control of chemical substance

- Reduce chemical spills

- Improve employee awareness

- Flow back water objectives

- Minimize the release of flow back water

- Improve employee awareness

Targets of the company

- Reduce the use of dilate acid CO2 by 10% on 2017.

- Eliminate chemical that contain carcinogens.

- Conduct of emergency response drills for chemical substance safety .

- Development of chemical substance management systems.

- Reduce the amount of flow back water by 30% by 6/6/2017.

- Reduce number of spill by 50% by 26/5/2017

- Train employee within a year.

Reference : biltayeb book

Responsibility

- Environment management team

- Managers

- supervisors

- EMS coordinators

Reference : biltayeb book

5 environmental and management program

1- Purpose

Providing the structure and body of our company, were the employees has to track it to achieve the objectives and targets of the company

2- Scope

Environmental and management program gives a plan written by the EMS team, were it shows the action plan needed to achieve the target and objective in set of time for the success of the EMS.

Environmental management program(s)

An environmental Management Program is a tool used to guarantee that the policy is taken into action to avoid any undesirable impacts and insure to reach the positive benefits of the projects by following different sit of activities. A company writes program with careful research and planning. Information and specifications on how to successfully reach the specified targets and objectives must be written in the program. Furthermore, a description of the time scale and the person in charged to implement the organization’s environmental policy must be written. Table ( ) shows hydraulic fracturing environmental program made by our company were it shows the objective and targets related to the significant aspects of hydraulic fracturing process and it’s relevant action plan to achieve the goal of our company. Additionally, The Table below include responsibilities and schedules as far as those objectives and targets are concerned.

| Objective | Target | Action Plan | Person in charge | schedule |

| Reduce green house gases emissions | reduce greenhouse gas emissions by 30% by 2019 | Chemical and safety engineer | 2019 | |

| Reduce fracturing fluid | Reduce the amount of fluid used in fracking by 30% in 2020 | Increasing recycling of fracturing fluid | Process engineer and production engineer | 2020 |

| reduce usage of hazardous chemicals | Reduce usage of hazardous and toxic chemicals by 20% | Replace it with no toxic chemicals | Chemical Engineer | 2020 |

| Reduce spills spilling | Reduce 20% of spills incidents by 2019 | Better storage and transportation | Environmental

And Safety engineer |

2019 |

| Reduce produce water (flow back water ) effect | Reduce production of flow back water by 20% | Process and production engineer | 2020 | |

| Reduce radioactive materials discharge | Reduce radioactive material presented from flow back water while discharging it | Make filtration and percentage test before discharging | Chemical engineer

Safety engineer |

2019 |

3 Procedure

Firstly, EMP provides action plan, responsibility and time required to achieve the listed objectives and targets.

Every member in the EMS has a role to accomplish the goal. The team is assigned to make an action plan with cost associated for the EMP including a schedule and identifying the recourses required for the action to be encountered. Additionally, it is the EMS coordinator responsibility to check, review and discus the EMP with relevant department managers regularly to ensure that the progress is achieved in the mentioned period. Also, The coordinator is responsible to regularly report to the safety, training and environment manager the status of environmental program.

Any new development or products and services that are applicable to achieve the project will be used.

4 Responsibilities

The responsibility of the environmental management program rests on EMS Manager and the team.

6 structure and responsibility

1 Purpose

All members in the company should be aware of their role and responsibility in order to achieve the required objectives and targets.

2 Scope

Classify the responsibilities, authorities and interrelationships of environmental recruits.

Structure and responsibility

To achieve successful EMS, our company clearly classified every recruitment from the top manager tell the operator his role and responsibility in regard to reach the targets and objectives. Top management or manager role is to provide all needed resources to the team and support them financially and keep up to date with the individual to ensure that EMS requirements are implemented according to 14001 international standards and done correctly. Furthermore, our top management selected an Environmental Management Representative

His tasks include: a) Ensuring that environmental management system requirements are established, implemented and maintained in accordance with this international standard; b) Reporting on the performance of the environmental management system to top management for review as a basis for improvement of the environmental management system [110]. Furthermore, EMR formed a team that will help him in constructing the EMS. Company EMS coordinator

Hence there is the need for an EMS coordinator, and an Environmental Management Team (EMT), all of whom will play a role in developing and promoting the EMS. • The EMS coordinator will be responsible for identifying, assigning, scheduling, providing the necessary support for, and ensuring completion of all tasks relating to the EMS. The EMS coordinator works closely with the EMR and the EMT. The EMS coordinator is also responsible for maintaining the EMS manual, under the leadership of the EMR. 125 • The EMT includes members of the activity who are responsible for representing their area or department in several sides of the EMS, such as identifying environmental aspects, objectives and targets [114]. In relation to AGOCO, there is the need for a modification of the management structure. Hence, Figure 31, which was shown in Chapter 7, is modified and the outcome is shown in Figure 32. Since the old structure focuses entirely on exploration, production and supply, it is important to integrate environmental issues into the overall objective of the company. This implies that the existing structure will not be effective in terms of meeting this overall objective which includes the comprehensive nature of environmental issues. Figure 32 presents this new structure for AGOCO, for the implementation and operation in accordance with ISO 14001.

The managers are divided into five top managers were each of them will define the overall role, the responsibilities and the authorities for the EMS and ensuring that it works. in addition, top managers are required to find out with their team the environmental significant aspect associated with their particular department and the required effort they have to put for achieving the targets and objectives .Also, they take part in environmental management programs, appoint and supervise internal auditors.

The safety, training environment manager will be responsible for appointing a full-time EMS coordinator to supervise that the environmental operation of the company is achieved. The EMS coordinator will be conducting routine checks to make sure that training programs are conducted as planned and done by qualified personnel and focus on achieving the set objectives.

Table 15 gives a summary of the responsibilities and the level of involvements in order to make the EMS effective. This Table is divided into seven columns and it shows the tasks to be conducted under the EMS and various responsibilities. From the Table it can be seen that it is very important for the chairman to approve the company’s environmental policy for the EMS to be effective. An approval of the policy is also a sign of commitment by top management as required by ISO 14001. It can also be seen that the EMT, line staff and the general managers are involved in all tasks related to the EMS. Making this group of people become involved in all tasks concerning the EMS is crucial, since it gives them the chance to explore the range of job functions and the various skills that make up the company.

It can further be seen that the audit team also is involved in only few tasks concerning the EMS.

This team assists in setting the general objectives towards good governance on the environment and check to make sure these objectives are met or even improved. Finally, one can observe that the field supervisors are also involved in some tasks since they are in charge

| Departments | Top management | HSE | HR | Financial | Engineering | Drilling | Production | chemical | FD | Safety, Training environment Manager |

| Environmental

Policy |

approval | involve | – | |||||||

| Identify environmental aspect of product | – | – | – | |||||||

| Legal requirements | approval | – | – | |||||||

| Establish environmental objective and targets | Approval | – | – | |||||||

| Environment management programme | Approval | – | Responsible | |||||||

| Auditing | Approval | Involve | Involve | Involve | Involve | Involve | involve | Involve | ||

| Coordinates communications with interested parties | Approval | involve | ||||||||

| Develop budget for environmental management | Approval | Responsible | Responsible | |||||||

| Maintenance | Approval | Responsible |

7 Training and awareness

Purpose:

The purpose of training and awareness stage is managing training courses for the employees to enhance the company’s efficiency and to improve achieving the set targets.

Scope:

EMSH employees and staff will have a training courses to be aware and conscious of the actions that results from the significant environmental aspects.

Procedure:

The training program will help the company’s staff and employees with an overview of the EMS requirements as a method of managing environmental aspects and impacts. In order to achieve the requirements there is two ways need to be followed:

- Firstly, a baseline training of the entire Environmental Management System of the organization must be given to the employees; basically it is training course that prepare the staff about the importance of environmental policy and achieving the objectives and targets.

- Secondly, specific training is divided into two areas, the first area is to offer a course about operations that may result from a significant environmental impacts. in the other hand, a course for emergency awareness and response and be able to deal with such actions professionally.

The following table introduces training courses provided by EMSH Company for minimizing the hazardous effect of hydraulic fracturing:

| Requirement training | Description of the training | Methodology | Frequency | ( period of training |

|

-Giving courses about type of chemicals and their classification and their level of hazard. |

|

Once a year | 1 month |

|

-Train the employees and staff how to deal with chemicals.

-How to take safety precautions when hazards occur. |

|

Twice a year | 2 months

( 1 month theory presentation and 1 month practically) |

|

-prevent the amount of toxic gas that released from the ground. |

|

Twice a year | 1 month |

|

-give the employees an idea about treating the amount of flow back water.

-storing the produced water. -reusing the flow back water in other hydraulic fracturing process. |

|

Once a year | 2 months |

Responsibility

EMS training and awareness is provided by the top manager ensuring that resources are available to establish and maintain the objective of the significant environmental aspects, and identifying specific training course to enhance the company’s activities.

8 Communication

Purpose:

The main purpose of this step is to establish procedures for internal and external communication for the company.

Scope:

The communication step requires establishing report in order to receive and respond to related communication from internal and external concerned participants.

Procedure:

Communication requires a perfect plan to be done in order to ease the procedure for the company’s programs to achieve the environmental policy and accomplish all objectives.

Communication has a great impact on the company’s EMS system as it’s an achieving support for the ems and establishing a process on objectives and targets where both employees and stakeholders are involved. External communication has a significant rule as it is used for determining the activities, improving facilities and environmental problems. The one who is encharge for determining the communication methods is the EMS coordinator. Nowadays the techniques of communication are a lot such as: emails, telephones, internet, meetings, fax and letters. Communication in general is divided into two sections: internal communication and external communication.

– Internal communication:

The main aim of internal communication is to enhance the awareness of the EMS employees, determining audiences for EMS communication and continually and consistently message for all employees.

– External communication:

The aim is to improve the awareness of the EMS and external contributions in accomplishing objective and target. In this part of communications few things need to be considered as: environmental policy, objectives and targets and participant roles and responsibilities.

Responsibilities:

The responsibility will be given to someone who has the right to apply and assign task for the employees to enhance the company’s communication mostly a manager. Furthermore, this manager should have a strong personality and take the responsibility for any risk, mainly an environment manager, safety manager and EMS coordinator that take the responsibility of EMS communication.

9 EMS Documentation

1 Purpose

Shows the way of arranging the work materials in a document or electronic form contains information regarding the core elements of EMS with the interactions.

2 Scope

The company policy, procedures and instruction must be written in a form as standard structure for the company

The environmental management system documentation consists ofthe environmental policy and it is related objectives and targets, EMS procedure and environmental management program. Also,It should include briefly a description of the core elements of the management, the interaction between those elements and work instructions, and records of the organizationessential to guarantee the effective planning, operation and control of processes that relate to its significant environmental aspects. The location of all requirements and records of performance should be included too. Hence, it should be written in clear and understandable document form or electronic form.

Components of environmental management documentation:

- Defines environmental policy, approach & responsibility

- The environmental management procedures

- A list of environmental aspects and environmental impacts

- A list of the legal and other requirements

- Provide a list of work instructions, what? And how? With brief details

- Situation specific documents training, audit, results and records.

Procedures

There are four different levels for several types of documents and records that should be in EMS documentation. The levels are as follows:

- Level 1: Has the environmental policy plus EMS instruction booklet that describe the conformance by ISO 14001 standards.

- Level 2: Contain supporting regulations and rules of developing the documents and plans for implementing the EMS requirements for the KPETRO Company.

- Level 3: Includes the regular operating procedures and individuals work instructions that is needed to classify the approaches in order to deal with task-oriented actions that relate to environmental impacts.

- Level 4: Determine the records and forms that involve level 2 and level 3 documents. Furthermore, it includes the reference lists and reports and other supporting forms that were developed in agreement with EMS or regulatory requirements.

11 Operational control

Purpose:

The purpose of this process is to determine instructions for applying the operational control for the hydraulics fracturing processes and activities to achieve the significant environmental aspects.

Scope

The detailed procedure for processing each significant environmental aspect that is identified by the company will be mentioned and discussed in order to have a better and clear view for the employees to achieve their work properly .

Procedure:

The environmental management team follows a specific method to identify the environmental aspects and their impacts, then determining the significant environmental aspects that satisfies the environmental policy, objectives and targets and environmental management programs, to improve the performance for reaching the company’s targets. It is an important step to have an operational control for all companies to ensure the work procedures, and all the staff has a clear view of their job responsibilities.

EMSH activities that needs an operational control in order to minimize the effects of hydraulic fracturing such as: minimizing the chemical spills, treating the flow back water , have more than 30% to be either used for other beneficial processes that won’t affect the environment badly and treat it for land and agriculture uses.

The following is the operational control for EMSH significant environmental aspects:

Toxic chemical spills:

In hydraulic fracturing process a large amount of water with mixture of chemical additives are injected down to the shale formation such as: toxic slicking agent and corrosion inhibitors. Chemical spills has a major effect on the environment when its accidentally spilled from a leakage while producing or transportation.

The effects of chemical spills depends on the level of the chemical toxicity and the amount of chemical spill, as their effects on the ecosystem is huge and will cause many diseases and illnesses for the humans such as :

- Cancer

- Blindness

- Death

For agriculture and wildlife:

- Extinction of animals

- Animal death

- desertification

- extinction of plants and trees

EMSH Procedures:

EMSH Company ensures to reduce the effect of the chemical spills as it is considered to be one of the significant aspects and implement various environmental safety solutions:

- Attach a sensor that detects the occurrence of the radioactive materials in the flow back water.

- Installing a direct pipe attached to the well head to carry the flow back water straight away to the treatment station.

- Install double casing for the flow lines.

- In case of long term storage, the company adapts a system of closed loop fluid handling for other hydraulic fracturing process.

- Periodically flow lines maintenance

https://fracfocus.org/hydraulic-fracturing-how-it-works/drilling-risks-safeguards

12 emergency preparedness and response

Purpose

The determination of preparing for essentials environmental emergency procedures that need to followed to deal with the dangerous and hazard situations in order to prevent any risk or injury, which can affect either the environment or human.

Scope

The entire employee in the company, including all the staff’s departments must learn and understand the various ways to deal with each situation carefully to avoid any hazards risk, and know the safety methods, involving all the actions at the company. Especially when we deal with threats chemicals where it can leads to death or by side effects that can be caused by the contaminated of flow-back water.

Procedure

For chemicals:

1. Evacuate and Aid

• Do not move the spills and evacuate the area immediately.

• Dispose of any polluted clothing/flushing any uncovered parts with water.

2. Confine

• You can close the doors and windows plus, isolate the chemical spills without implicating yourself in danger.

3. Report

• Call the emergency number or EHS department and inform them of current situation including name, area, and type of the chemicals.

4. Secure and Clean

• Manage all the entrances to the affected area and prevent everyone from entering until we take the necessary steps.

• Let EHS guide you for the cleaning methods.

For flow backwater:

Flow backwater and can be treated from Contaminations which contains high concentrations of chemicals, sand and radioactive minerals that water can be acquired after hydraulic fracture operations, where the best way to solve this problem by:

- Disposing the contamination flow backwater (on certain conditions and specific ranges) after treating.

- Reused the noxious flow backwater after treatment (recycle it).

In the case of emergency leakage, or high pressure that can be released during hydraulic fracture operations, it is recommended to:

- Report the Emergency Water Supply (EWS) and operations services to ask them for assistance, also try to follow their instructions to avoid any injuries.

- Stop running the hydraulic fracture operations immediately and Inform the workers about the hazards that high pressures can caused where most of the time it is lead explosions and high-energy discharges.

- Examine and test iron and other equipment’s from sand erosion

- Maintain and fix the problem to ensure the operation work well ,by managing the pressure or detect the affected leakage.

http://www.jst.umn.edu/safety-moments

https://www.osha.gov/Publications/OSHA3763.pdf

13 Monitoring and Measurement

Purpose

It is to pursuits the features and deeds of HMES company’s environmental monitoring and measurement management system.

Scope

It’s a gathering of environmental data which includes operations and activities that have the prospective significant environmental impacts of the hydraulic fracture.

Producers

It’s an operating system for monitoring and measurements the hydraulic fracturing procedures, which record the HMES company operational monitoring information. However, it is to tracks the operational performance and characteristic that must be checked periodically. Also; it is an evaluation technique that the company needs to stick with environmental legislation and regulation.

| Activities | Indicators |

| Leakagedetectors |

|

| Corrosion monitoring |

|

| Ground water monitoring |

|

| Training courses |

(attending and completing the courses is mandatory ) |

http://www.elibrary.dep.state.pa.us/dsweb/Get/Document-48361/383-3000-001.pdf

17 Management review

Purpose

Gives instructions regarding the EMS of our company to top management review to guarantee that the EMS is going smoothly, and therefore, make the required check to see if it needs any improvement.

Scope

All EMS elements with enough information should be included, in order for the management to take decisions regarding the state of the EMS is it suitable and effective to achieve the required purpose or not.

Management review process

Management review is an important part as it shows the continuity of the company’s EMS. Where it reflects the needed preventive and corrective action required for the improvement of the system. It has all the elements of EMS and the possible changes needed for them. Also, a scope of organizational services and products such as the environmental impacts and how it relates the environmental problems of the company to the business procedures must be included. it should be done and conducted every year.

Procedures

Every year KPETRO conduct a review of the EMS components by the top management. the top management review it and do checks to see EMS effectiveness and adequacy. any comment and correction will be recorded in management review form.

- KPETRO top management prepares a review of the EMS each year.

- The top management make a revision of all the EMS requirement for the company, and make sure that every step is done properly such as:

- Monitoring and Measurements and their results.

- Objective and target of the company.

- Legal and requirements

- Other information related to the EMS of the company

- Agendas and effectiveness of the work is reviewed periodically by the top management.

- All the results of the management review are documented on the management review form.

- All the employees are aware about the results of the management review through conducting a meeting by the top management.

Responsibility

• Top management is the one who is responsible for management review

Chapter 4

Analysis and discussion of results

Chapter 5

Conclusion

In conclusion, the EMS is one of the most important organizations that need to be done to preserve our land and earth. Either following the standards ISO 14000 or the local standards will be the same, since both of them aim for one think, which is maintaining better life and better environment. Activities such as hydraulic fracturing are really need to be controlled because of the harmless side effects that end with poor environment. Chemical additives and flow backwater are the most harmful aspects from this process. Controlling theses significant aspects means controlling the hydraulic fracturing process.

Reference

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Energy"

Energy regards the power derived from a fuel source such as electricity or gas that can do work such as provide light or heat. Energy sources can be non-renewable such as fossil fuels or nuclear, or renewable such as solar, wind, hydro or geothermal. Renewable energies are also known as green energy with reference to the environmental benefits they provide.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: