Bisleri International Performance Measurement System

Info: 3380 words (14 pages) Dissertation

Published: 16th Dec 2019

Tagged: Information Systems

1. Description of the Organization

1.1 Introduction

Bisleri International Pvt. Ltd. Is an Indian company best known for selling bottled water In India. Known all over India as the brand that pioneered the concept of mineral water, bottled with its distinct green label, today Bisleri is a household name (Bisleri 2018b).

Bisleri, an Italian mineral water company was launched in Mumbai in 1965 when the “Parle group” purchased Bisleri from Italian entrepreneur “Signor Felice Bisleri” in 1969. As a soft drinks company, Parle had Thums Up, Gold Spot and Limca (cola, orange drink and lemonade) and used the name Bisleri to sell water in glass bottles which they later switched to PET containers and launched soda with two variants — carbonated and non-carbonated mineral water. Parle sold their soft drinks brands to Coca-Cola in 1993 for Rs. 400 crores. After this, Parle decided to bring safe drinking water under the brand name Bisleri (Ghaswalla 2013).

1.2 Core values and Objectives

Bisleri thrives in India as the main brand for supplying mineral water due to the set Core values they are build upon. These are Quality they have to offer where every person has access to clean drinking water and their Passion to constantly drive from “Consumer Satisfaction” to “Consumer delight”. Leadership quality helps to control the overall growth of the team and treating all members with dignity and constantly keeping them motivated. Any success without Integrity is good as failure (Bisleri 2018e).

1.3 Size of the organization

The company has 52 bottling plants across India, which includes plants at Delhi, UP, Jaipur, Mumbai, Goa, Bangalore, Chennai and Rudrapur, which are owned by the company. “In view of growing consumer needs across India”, Bisleri are setting up 25 new bottling plants to fulfill the growing demands. On a national level, there are 2,000 trucks-on-call for Bisleri, while the number of trucks averages 300 and 250 in the Mumbai and Delhi markets. Maharashtra contributes 30 per cent of the company’s total sales (PTO India 2013).

The bottled water industry in India witnessed a growth in the 1990s after Bisleri launched its packaged drinking water in India. Its significance has increased with the rise in health awareness, poor quality of tap water and the ease of availability of bottled water at a cheaper rate. India’s packaged bottled water industry to reach Rs.160 billion by 2018 (ANI 2014).

The estimated industry size touched the 10,000-crore mark in 2012-13 fiscal year which show a growth by 19% p.a. Bisleri holds 60% share in packaged drinking water ahead of its competitors such as Kinley and Aquafina (TNN 2008).

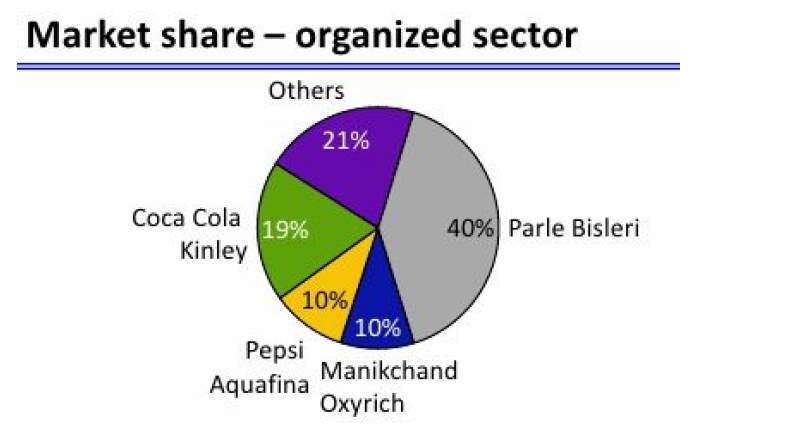

1.4 Market Structure

According to Bureau of Indian Standards (BIS), there are 1200 bottling plants and 200 brands of packaged drinking water in India (nearly 80% of which are local). The bottled water market is dominated by major player such as Parle, Coco-Cola, Manikchand, Tata-Mount Everest, Pepsico. Although we have a large number of players, Parle was the pioneer in this segment among the major player when it was launched in India in 1965 (Chopra 2013, pp.133–135).

Source : (Chopra 2013)

According to report from Statista India (2018), Bisleri continues to be the top brand for selling packaged drinking water with a 44% in shares. Coca-Cola’s Kinley follows with 31% share, followed by Aquafina at 15%. Other smaller brands include Parle Agro’s Bailley, Kingfisher and McDowells No.1.

2. Procurement Function

A functional and cohesive procurement function is vital to improving profitability. While clear standard operating procedures are important, it takes more to create efficiencies. The procurement structure is just as important to provide efficiency. Adopting one that aligns with long-term business goals and daily operations can help your company function properly (Lohrey 2017).

2.1 Resources

When it comes to resources, water is the main raw material to be procured and it is mostly sourced from lake, river, bore-well. Ground water constitute major water source and they have ties with the municipal corporation to supply water for treatment and filtering. Bisleri has 18 co-owned plants, 58 co-packers, 13 franchisees in India. Water forms the prime procurement function and holds the most value in-terms of quality and efficiency (TNN 2008).

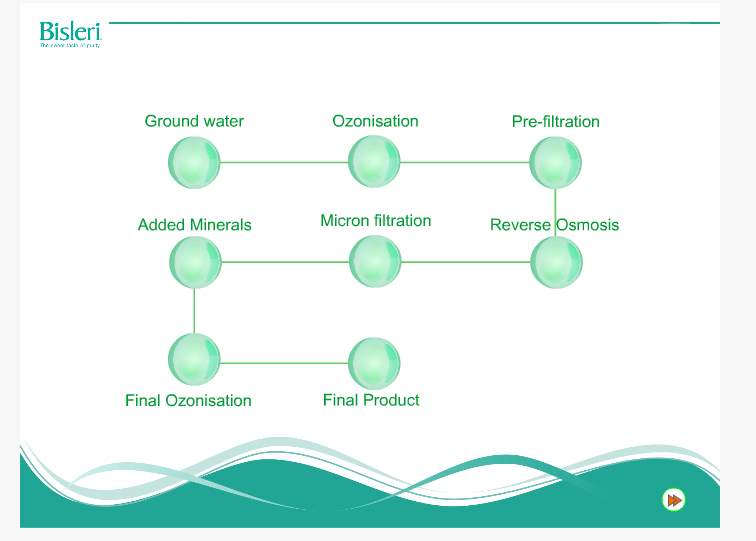

Each drop of Bisleri undergoes a stringent 6-step purification process of Ozonisation, Pre-filtration, added minerals, micron filtration, reverse osmosis (RO) and Final Ozonisation (Bisleri 2018c).

Source: (Bisleri 2018c)

This rigorous treatment ensures that water which is packaged is clear and safe for drinking.

As water is scarce, Bisleri has come up with few initiatives inorder to preserve the water and decreasing its overall dependency on municipality supplies.

1. Rain-water Harvesting: India is blessed with the highest amount of rainfall in the world. However, it is unfortunate that 95% of this fresh rain water is lost through run off. It is an initiative active in Bangalore, Chennai, Mumbai where the main purpose is to conserve every bit of water which is washed through run-off. Bisleri facilities are equipped with rain water harvesting systems and harvest 77.1 million litres of rainwater every year at Bisleri plants which forms the way of sourcing apart from ground water (Bisleri 2018d).

2. Check Dam Project: This project was first introduced in 2001 at a village in Gujarat. The main purpose is to conserve rain water by building and restoring Check Dams. Check Dams help store surface water for use both during and after the monsoon and helps in ground water recharge of the area. Recharge of water helps in raising the water table in the area. Availability of water ensures farming all year round and increase of agricultural yield by multi-cropping, thus, empowering growth and success. Such initiative has a huge impact on the reputation and pivotal for the growth in the sector (Bisleri 2018a).

When it comes to Human resources, Bisleri has over 2000 employees spread across all the department of organization, from the plant directors to its material management, finances and sales team (TNN 2008).

2.2 Organization Structure

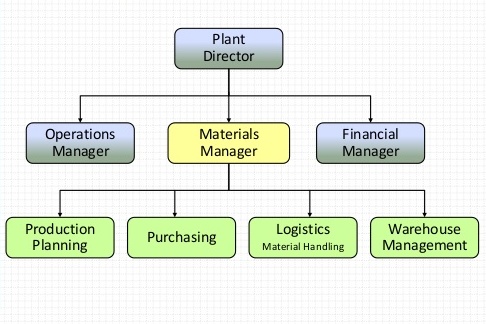

According to the Chairman, Mr. Ramesh Chauhan, Bisleri operations are centralized and areas such as purchasing, finance and marketing comes under one roof (Vijayraghavan 2009).

Although the organization has a wide supply chain, the main organization structure is divided into primary and secondary activities. Primary activities form the integral part of the supply chain where the value is created to the organization. It lies at the initial stages of development, such as the procurement and the role of production, logistics and warehouse management. Sales, Research and development sector (R&D), Marketing forms the support activities that guides the company’s core values and structure in the market (Vijayraghavan 2009).

2.3 Supply Chain Structure

Bisleri has over employees working under different department spread over all their bottling plant and factories. Although the supply chain reaches out to all the department, the core emphasis is based at the bottling plant where the sourcing, production, manufacturing and warehouse management is crucial that generates the entire supply chain value.

Following diagram clearly marks the part of the supply chain which generalizes the company structural value.

Source: (PTO India 2013)

The hierarchical structure of the supply chain is designed in a manner that each department has the same amount of power and can voice an opinion in any matter relating to the supply chain. This allows for smooth functioning and builds the system the way it should perform according to company’s goals (Vijayraghavan 2009).

3. Reasons for introducing a Performance Measurement System.

The company has implemented quality, sourcing and hygiene measurement tools to identify issues and to rectify those within the departments, but those system are not coherent and robust enough to deal with all types of matter regarding the price, quality at an operational level.

One of the key activities of the company is of sourcing water. Bisleri plant in Delhi was shut down in 2014 for illegal use of groundwater. The plant has been drawing 3.31 lakh litres of groundwater every day without requisite approval. The issue becomes even more critical as Delhi has been facing a perennial water crisis. Bisleri needs to provide an approval margin to draw certain amount of water per day (Singh 2014).

Another key reason for implementation is regarding the quality, according to the study conducted by scientists in the article by Author, 93% of bottled water sold in India (specifically in cities like Mumbai, Delhi and Chennai) has tiny plastic residues creating micro-plastic contamination which involves companies like Parle, PepsiCo. Although the companies claim to have quality control measures, sanitary manufacturing practices, filtration and other food safety mechanisms, issues are then raise regarding the packaging part of the supply chain (TOI 2018).

Such issues within the procurement and initial stages of their supply chain creates a huge risk surrounding company’s reputation, brand image and the organization values that echoes “safe drinking water”. So, a performance system would conduct and analyze matter influencing decision in every department and rating them according to their function and creating a robust system.

4. Implementing Performance Management System

Performance Measurement System (PMS) is an ongoing process which, once implemented, is designed to provide companies with a framework around which they can create a sustainable programme to encourage, develop employee’s contribution and improve their overall performance. This would enable to create a strong employee performance and improve the standard and potential in each department by self-evaluation (Heathfield 2018).

PMS will be implemented at a basic stage within the procurement, logistics department to get the standard methodology which then would be implemented across the entire supply chain.

TPM involves 5 stages which are as follows (Bjorn and Fagerhaug 2002).

1. Determining the performance categories to measure:

This forms the primary stage of the assessment wherein it focusses on designing the performance measurement system to think through and reacquaint themselves with the organization. According to the issues mentioned in the procurement stages activities, the categories which needs priority and utmost important are Quality and Sourcing consideration. Every organization would be having some sort of performance measurement system, for this reason the new system would work simultaneously and eliminating the one which has less impact in the organization. PMS will be implemented at a basic standard to understand the current activities and what needs to be improved.

2. Develop performance indicators:

The most important element of a PMS is the set of performance indicators you will use to measure your organization’s performance and business processes. The purpose of this step is to develop the performance measurement system with an appropriate number of relevant and precise performance indicators. Quantifying the indicators with suitable methods to collect data is the key aspect required to be addressed. Quality metrics are a key component of an effective quality management plan and are the measurements used in ensuring customers receive acceptable products or deliverables. For such quality would be benchmarked against the set standard prescribed the government or according to the Quality standard.

3. Establishing Performance objectives:

Performance objectives would be designed in a way that it can be realistic and urging each department to achieve the set measurement value at all manner. This can be done internally by identifying the best performers and using them as targets and trying to achieve those targets at a regular basis. Externally analysis can be done by examining the methods and measures of the competitors, which can influence the system to better equipped with data processing and getting to know how others are performing in the industry. It is a challenging methodology as it would not be easy to get access on other company’s internal activities and thus can be used as a secondary benchmarking analysis.

4. Testing the Performance measurement system:

As the system is new and methodology will differ from the existing system, employees and managers would need training on how to manage user access, what the various outputs means and how to achieve the given targets.

Since most of the issues addressed are at the initial phase of the supply chain, this system would heavily monitor the outputs and will try to rectify the mistakes at the early stage of procurement and its operation.

5. Monitoring and Review:

Implementing a system is one thing, monitoring its operation in the organization is key aspects to determine the overall approach and existence of the system. This can be achieved on a weekly or monthly basis, where quantifiable data will be compared and results will be analyzed. As Bisleri is a water packaging company, weekly approach towards measurement will be well suited as sourcing, hygiene and purification stages forms the core areas of the organization.

5. Benefits of the Performance Measurement System

An effective performance management system can play a very crucial role in managing the performance in an organization(Juneja 2017):

- Improving decision making within the various departments of the organization and the system being transparent.

- Ensuring each employee understands what is expected from them interms of purchasing, sourcing ad quality factors and equally ascertaining whether the employees possess the required skills and support for fulfilling such expectations.

- By evaluating the readiness of the employees for taking up higher responsibilities and thereby providing a feedback to the employees on their current competencies and the need for improvement.

- Highlights the areas where the firm is over-achieving and crediting them, while providing solution and feedback at the stages where needs improvement.

- Appropriate and accuracy in data collection can avoid any issues related to sourcing and quality which can hindrance the overall success of the company like Bisleri.

- Establishing a clear linkage between performance and compensation while distributing incentives and rewards on a fair and equated basis.

Thus, PMS can improve organizational performance, employee retention and loyalty, improved productivity, overcoming the barriers to communication, clear accountabilities, and cost advantages which can drive company’s core value and beliefs towards its ultimate goal and reward it with success and profit.

6. Bibliography

ANI 2014. India’s packaged bottled water industry to reach Rs.160 billion by 2018. Business Standard India. Available from: http://www.business-standard.com/article/news-ani/india-s-packaged-bottled-water-industry-to-reach-rs-160-billion-by-2018-114050800490_1.html [Accessed April 17, 2018].

Bisleri 2018a. Check Dams | Bisleri. Available from: https://www.bisleri.com/check-dams/#tillhere [Accessed April 22, 2018].

Bisleri 2018b. History | Bisleri. Available from: https://www.bisleri.com/about-us/history/ [Accessed April 17, 2018].

Bisleri 2018c. Purification process | Bisleri. Available from: https://www.bisleri.com/purification/ [Accessed April 22, 2018].

Bisleri 2018d. Rainwater Harvesting | Bisleri. Available from: https://www.bisleri.com/rainwater-harvesting/ [Accessed April 22, 2018].

Bisleri 2018e. Values | Bisleri. Available from: https://www.bisleri.com/about-us/values/ [Accessed April 17, 2018].

Bjorn, A. and Fagerhaug, T. 2002. Column: One Good Idea: Eight Steps to a New Performance Measurement System. Available from: http://asq.org/quality-progress/2002/02/one-good-idea/eight-steps-to-a-new-performance-measurement-system.html [Accessed April 22, 2018].

Chopra, P. 2013. Marketing of packaged drinking water in India. , pp.129–157.

Ghaswalla, A.N. 2013. No regrets selling Thums Up, says Bisleri chief Ramesh Chauhan. @businessline. Available from: https://www.thehindubusinessline.com/companies/no-regrets-selling-thums-up-says-bisleri-chief-ramesh-chauhan/article23106362.ece [Accessed April 17, 2018].

Heathfield, S.M. 2018. What Is Performance Management in the Workplace? The Balance Careers. Available from: https://www.thebalancecareers.com/performance-management-1918226 [Accessed April 21, 2018].

Juneja, P. 2017. Benefits of a Performance Management System. Available from: https://www.managementstudyguide.com/benefits-of-performance-management-system.htm [Accessed April 22, 2018].

Lohrey, J. 2017. Structure of a Procurement Organization. Available from: http://smallbusiness.chron.com/structure-procurement-organization-80305.html [Accessed April 20, 2018].

PTO India 2013. Bisleri to set up 25 new bottling plants. Business Standard India. Available from: http://www.business-standard.com/article/companies/bisleri-to-set-up-25-new-bottling-plants-109070200024_1.html [Accessed April 22, 2018].

Singh, D. 2014. Delhi: Bisleri plant told to shut down over illegal use of groundwater. https://www.hindustantimes.com/. Available from: https://www.hindustantimes.com/delhi/delhi-bisleri-plant-told-to-shut-down-over-illegal-use-of-groundwater/story-k3yl9Xix439DuOJkgNFDgL.html [Accessed April 21, 2018].

Statista India 2018. Bottled Water – India | Statista Market Forecast. Statista. Available from: https://www.statista.com/outlook/20010000/119/bottled-water/india [Accessed April 17, 2018].

TNN 2008. ‘Bulk water accounts for 60% of sales’. The Economic Times. Available from: https://economictimes.indiatimes.com/opinion/interviews/bulk-water-accounts-for-60-of-sales/articleshow/2908577.cms [Accessed April 17, 2018].

TOI 2018. Study finds plastics in bottled water from Mumbai, 2 other cities – Times of India. The Times of India. Available from: https://timesofindia.indiatimes.com/city/mumbai/study-finds-plastics-in-bottled-water-from-mum-2-other-cities9-nation-study-finds-plastics-in-90-of-bottled-water/articleshow/63323833.cms [Accessed April 21, 2018].

Vijayraghavan, K. 2009. Bisleri’s big ambitions for the brand. The Economic Times. Available from: https://economictimes.indiatimes.com/magazines/brand-equity/bisleris-big-ambitions-for-the-brand/articleshow/4883758.cms [Accessed April 22, 2018].

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allRelated Content

All TagsContent relating to: "Information Systems"

Information Systems relates to systems that allow people and businesses to handle and use data in a multitude of ways. Information Systems can assist you in processing and filtering data, and can be used in many different environments.

Related Articles

DMCA / Removal Request

If you are the original writer of this dissertation and no longer wish to have your work published on the UKDiss.com website then please: